Cyclic Fatigue and Torsional Resistance of Four Martensite-Based Niti Reciprocating Instruments

Abstract

Objective: To evaluate cyclic fatigue and torsional resistance of Reciproc Blue R25 (VDW, Munich, Germany), WaveOne Gold Primary (Dentsply Maillefer, Ballaigues, Switzerland), ProDesign R (Easy Equipamentos Odontológicos, Belo Horizonte, Brazil), and X1 Blue File (MK Life, Porto Alegre, Brazil) nickel titanium (NiTi) martensite reciprocating instruments.

Methods: In each group, ten instruments were tested for cyclic fatigue resistance using a stainless-steel artificial canal (curvature angle of 80° and radius of 3 mm) and ten instruments for torsional failure according to ISO 3630-1 standard. The surface of the fractured instruments was examined under scanning electron microscopy (SEM) at ×250 magnification. The results were compared statistically with one-way ANOVA and post hoc Tukey tests and the alpha-type error was set at 5%.

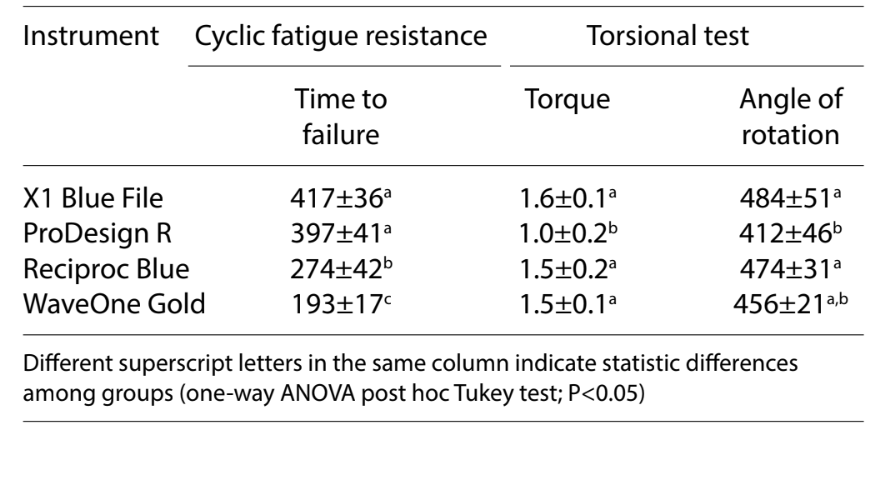

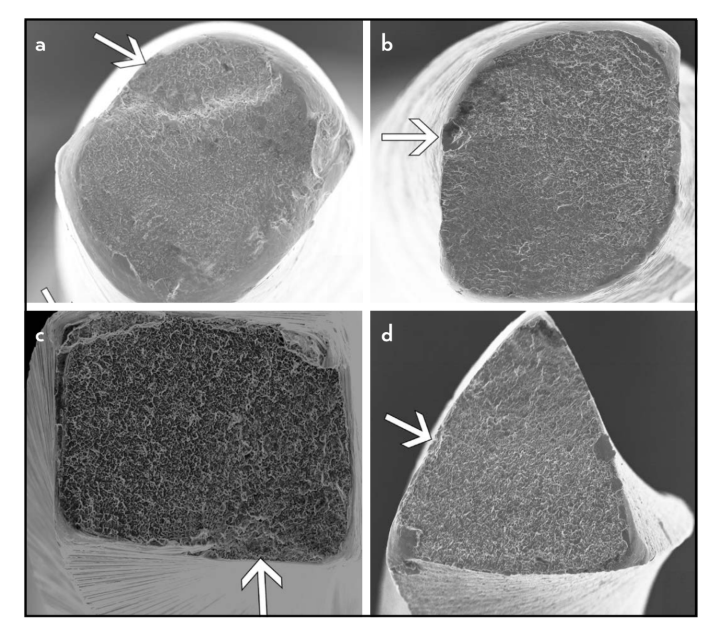

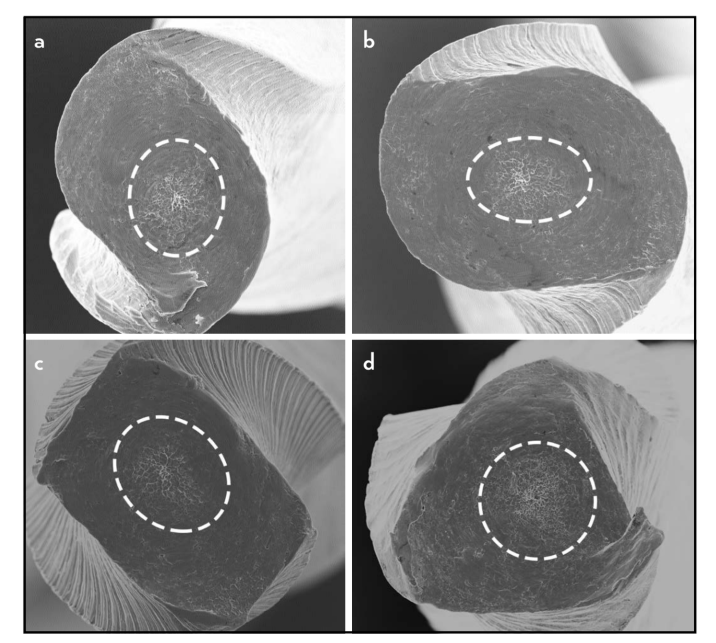

Results: X1 blue file and ProDesign Rinstruments showed highest time to fracture than Reciproc Blue and Wave One Gold (P<0.05). However, no differences were found between X1 Blue File and ProDesign R (P>0.05). In addition, Reciproc Blue demonstrated highest time to fracture than WaveOne Gold (P<0.05). The lowest torsional resistance (1.0±0.2 N.cm) and angle of rotation (412°±46) was observed in the ProDesign R group (P<0.05). SEM analyses of fractured surfaces showed a crack initiation area and overload fast fracture zone after cyclic fatigue test, and concentric abrasion marks with microvoids at the centre of rotation after torsional failure experiment.

Conclusion: Overall, X1 Blue File and ProDesign R showed higher cyclic fatigue resistance than Reciproc Blue and WaveOne Gold instruments, while ProDesign R had the lowest torsional resistance and angular rotation values to fracture. SEM analysis of all instruments demonstrated typical failures features in both cyclic fatigue and torsional failure tests.

Introduction

Nickel-titanium (NiTi) alloys usually are softer than stainless steel, have a low modulus of elasticity but they flexural are tougher and more resilient, and show shape memory and superelasticity. The latter two properties are the main reasons why NiTi alloys have succeeded for developing engine-driven instruments for root canal preparation. However, despite these mechanical advantages, NiTi instruments still present a risk of fracture, especially during treatment of curved root canals, which might compromise the outcome of endodontic therapy, which might compromise the outcome of endodontic therapy. In this way, several modifications have been proposed in their design, kinematics and manufacturing method (alloy type) aiming to enhance the mechanical properties in order to prevent fracture. According to some authors, the thermal treatment of the NiTi alloy changes the arrangement of its crystal structure, improving its flexibility and flexural.

Conventional NiTi alloy presents nearly equiatomic ratio of nickel (~56 wt%) and titanium (~44 wt%) elements and exists in two different temperature-dependent crystal structures named austenite and martensite phases. In the austenic phase, the alloy presents a superior superelastic property, while in the martensitic phase it has a better shape memory effect. Thus, martensite-based instruments have increased flexibility and higher cyclic fatigue resistance than the austenitic instruments of the same design. Therefore, various thermal treatments of the NiTi alloy have been suggested to produce endodontic instruments with improved mechanical properties including the Blue Technology (Dentsply Tulsa Dental Specialties, Tulsa, OK, USA), the Controlled Memory Wire (CM; Coltène Whaledent, Inc., Cuyahoga Falls, OH, USA), and Gold Technology (Dentsply Tulsa Dental Specialties). Also, the use of reciprocating movement was claimed to in- crease the resistance of NiTi instruments to fatigue in comparison with continuous rotation. However, despite these changes, martensite based NiTi endodontic instruments still might fracture due to torsional failure or torque load.

In the literature, martensite-based reciprocating instruments such as Reciproc Blue (VDW, Munich, Germany), WaveOne Gold (Dentsply Maillefer, Ballaigues, Switzerland) and ProDesign R (Easy Equipamentos Odontológicos, Belo Horizonte, Brazil) instruments have been extensively tested regarding their mechanical properties. Recently, a new martensite-based reciprocating instrument, named X1 Blue File (MK Life, Porto Alegre, Brazil), was launched in the market. According to the manufacturer, this instrument exhibits an inactive tip (ISO size 25) and convex triangular cross-section. So far, the cyclic fatigue and torsional strength of X1 Blue File instruments were not tested yet. Therefore, the purpose of this study was to compare the cyclic fatigue and torsional resistance of the X1 Blue File with ProDesign R, Reciproc Blue and WaveOne Gold reciprocating instruments.

Materials and methods

Eighty new 25 mm long instruments of four NiTi reciprocating systems (n=20) were selected for cyclic fatigue and torsional failure tests: Reciproc Blue R25 (n=20; size 25 at the tip and a taper of 0.08 while after the initial 3 mm the taper was regressive) (batch #37631), WaveOne Gold Primary (n=20; size 25 at the tip and a taper of 0.07 while after the initial 3 mm the taper was regressive) (batch #1226916), ProDesign R (n=20; size 25 at the tip and a constant taper of 0.06) (batch #170096), and X1 Blue File (n=20; size 25 at the tip and a constant taper of 0.06) (batch #20171010). In each group, ten instruments were tested for dynamic cyclic fatigue and 10 instruments for torsional resistance. All instruments were previously examined for visible defects or deformities at ×20 magnification under a stereomicroscope (OPTZS; Opticam, Sao Paulo, Brazil). No defects were detected, and the selected instruments were submitted to the tests.

Cyclic fatigue test

The cyclic fatigue test was performed using a stainless steel custom made device that allowed a reproducible simulation of an instrument confined in a curved canal with angle and radius of the curvature of 80° and 3 mm, respectively, located 4 mm from its tip (tip #30, taper 0.08). This is not identical tip and taper but close to the size and taper of all instruments. As artifical canal was not identical to the tip and taper of the instruments, no torsional resistance is applied in the instrument. All tests were conducted in saline solution at 37°C and instruments (n=10 per group) were operated in a dynamic method using a 6:1 reduction handpiece (Sirona Dental Systems GmbH, Bensheim, Germany) powered by a torque-controlled motor (VDW Silver; VDW), according to the manufacturers´ recommendations. The electric handpiece was mounted on a device that enable precise and reproducible placement of each instrument into the custom-made artificial canal. The amplitude of the axial movement was 3 mm and the speed of the movement was set at 1 cycle (complete movement from the highest to the lowest point) for 2 seconds. The time to fracture was recorded in seconds with a digital chronometer and stopped when the file fracture was detected visually and/or audibly.

Torsional test

The torsional load was applied until fracture to estimate the mean ultimate torsional strength and the angle of rotation of the tested instruments (n=10 per group) using a custom-made device produced according to ISO 3630-1. The test was performed under 37°C to simulate clinical conditions and each instrument was pressed at 3 mm from the tip using a chuck connected to a torque-sensing load cell. The shaft of the instrument was fastened into an opposing chuck able to be rotated with a geared motor. The instruments were rotated in the counter clockwise direction at a speed of 2 rpm until instrument fracture. The torque load (N.cm) and angular rotation (°) were recorded using a torsiometer (ODEME; Luzerna, SC, Brazil) and the ultimate torsional strength and angle of rotation at failure were provided by a specifically designed computed software (ODEME Analysis TT; ODEME).

Scanning electron microscopy

A scanning electron microscope (SEM; JSM 5800; JEOL, Tokyo, Japan) was used to evaluate the topographic features of the fracture surfaces of all instruments after cyclic and torsional tests at ×250 magnification.

Statistical analysis

Data analysis revealed a bell-shaped distribution (Shapiro- Wilk test; P>0.05) and statistical analysis was performed amongst groups using one-way ANOVA and post hoc Tukey tests with an alpha-type error set at 5% (Biostat; Instituto Mamirauá, Tefé, Brazil).

Results

Means and standard deviations of time to fracture (cyclic fatigue resistance), maximum load torque and angular rotation to fracture are shown in Table 1. No statistical difference was observed between the time to fracture of X1 blue file (417±36 s) and X1 blue file (417±36 s) and ProDesign R (397±41 s) instruments showed highest time to fracture than Reciproc Blue (274±42 s) and Wave One Gold (193±17 s) (P<0.05). However, no differences were found between X1 Blue File and ProDesign R (P>0.05). In addition, Reciproc Blue demonstrated highest time to fracture than WaveOne Gold (P<0.05). The lowest torsional resistance (1.0±0.2 N.cm) and angle of rotation (412º±46) was observed in the ProDesign R group (P<0.05). SEM analyses of fractured surfaces showed a crack initiation area and overload fast fracture zone after cyclic fatigue test (Fig. 1), and concentric abrasion marks with microvoids at the centre of rotation after torsional failure experiment (Fig. 2).

Discussion

Instrument separation has been repeatedly reported by several authors since the advent of mechanical preparation with NiTi alloy instruments in endodontics and explained on the basis of excessive torsion and cyclic fatigue. Cyclic fatigue fracture occurs as a result of the alternating tension compression cycles to which the instruments are subjected when flexed in the region of maximum curvature of the canal, while torsional stress is produced when shear stresses exceeds the elastic limit of the metal causing plastic deformation and fracture. The present study was designed to compare the cyclic fatigue and torsional strength of 4 new martensitic NiTi reciprocating instruments named Reciproc Blue, WaveOne Gold, ProDesign R, and the X1 Blue File.

Overall, results showed that X1 Blue File and ProDesign R instruments showed a higher time to fracture than Reciproc Blue and WaveOne Gold instruments (Table 1). A longer cyclic fatigue life of NiTi instruments depends on many factors including their diameter, metal mass of the core, flexibility, cross-sectional design, and type of NiTi alloy. Found that large-tapered instruments used in curved canals can fracture after only a few rotations. The variable taper and large cross-sectional area of Reciproc Blue and WaveOne Gold compared to ProDesign R and X1 Blue File instruments, associated with the position of the curved segment of the artificial canals used in this study (4 mm from the tip), may explain their lowest values in the cyclic fatigue test. Moreover, it is also possible that differences in the thermal treatment of the NiTi alloy in each system have influenced the final outcome. In fact, a recent publication demonstrated that Reciproc Blue had a significant higher cyclic fatigue resistance than WaveOne Gold and M-Wire Reciproc instruments, which is in accordance with the present results. Apart differences on their thermal treatment and considering that NiTi instruments with a large metal core mass present a decrease in their cyclic fatigue life with cracks initiating mostly at their main edge, the larger cross-section and higher number of leading edges of WaveOne Gold instrument might explain its lower time to fracture compared to Reciproc Blue. SEM analysis of the instruments showed similar ductile fractographic appearances of cyclic fatigue fractures with microvoids. It was also observed crack initiation areas and overload fast fractures zones with no morphologic differences in the fracture surfaces of all evaluated instruments (Fig. 1).

Nowadays, although no specification, international standard, or consensus were reached regarding the use of custom-made artificial canals to evaluate the cyclic resistance property of NiTi instruments, this method has been previously validated and widely used in laboratory studies because it allows the standardization of the experimental conditions, increasing its internal validity. In the present study, efforts were made so that the artificial canal dimensions were similar to the tip and taper of the tested instruments, giving it a precise trajectory, as previously reported. Moreover, in the current study, a dynamic model was used aiming to simulate better the clinical use of the NiTi systems. Compared to static models, in a dynamic test, time to fracture increases as the stress applied to the instrument spreads along the shaft under back and forth movements. Finally, tests were performed with the artificial canal immersed in saline solution at 37°C, considering that this methodological procedure was associated with more reliable results, as body temperature seems to decrease the cyclic fatigue life of NiTi instruments.

Torsional fatigue test showed that the maximum torsional strength (1.0±0.2 N.cm) and angular rotation to fracture (412°±46) of ProDesign R instrument were significantly lower than the other systems (Table 1). These results suggest that ProDesign R requires a low torque to fracture by torsion which means a high chance of disruption if the tip of the instrument binds within the root canal space. This could be explained by its small taper (0.06), cross-sectional shape (S-shaped), and the high flexibility of its CM NiTi alloy type. On the other hand, the highest angular distortion of Reciproc Blue and X1 Blue File instruments (Table 1) could be an advantage in clinics because plastic deformation could predict an imminent fracture, indicating the moment to discard the instrument. SEM analysis of instruments submitted to the torsional resistance test demonstrated typical features of torsional fracture, i.e. concentric abrasion marks and fibrous dimples from the torsional centre (Fig. 2).

Conclusion

Overall, X1 Blue File and ProDesign R showed higher cyclic fatigue resistance than Reciproc Blue and WaveOne Gold instruments, while ProDesign R had the lowest torsional resistance and angular rotation values to fracture. SEM analysis of the fractured surfaces showed a crack initiation area and overload fast fracture zone after cyclic fatigue test, and concentric abrasion marks with microvoids at the centre of rotation after torsional failure experiment.

Authors: Emmanuel J.N.L. Silva, Carolina O. Lima, Victor T.L. Vieira, Henrique S. Antunes, Edson J.L. Moreira, Marco A. Versiani

References:

- Sattapan B, Nervo GJ, Palamara JE, Messer HH. Defects in rotary nickel-titanium files after clinical use. J Endod 2000; 26(3):161–5.

- Crump MC, Natkin E. Relationship of broken root canal instruments to endodontic case prognosis: a clinical investigation. J Am Dent Assoc 1970; 80(6):1341–7.

- Panitvisai P, Parunnit P, Sathorn C, Messer HH. Impact of a retained instrument on treatment outcome: a systematic review and meta-analysis. J Endod 2010; 36(5):775–80.

- De-Deus G, Silva EJ, Vieira VT, Belladonna FG, Elias CN, Plotino G, et al. Blue Thermomechanical Treatment Optimizes Fatigue Resistance and Flexibility of the Reciproc Files. J Endod 2017; 43(3):462–6.

- Zhou HM, Shen Y, Zheng W, Li L, Zheng YF, Haapasalo M. Mechanical properties of controlled memory and superelastic nickel-titanium wires used in the manufacture of rotary endodontic instruments. J Endod 2012; 38(11):1535–40.

- Shen Y, Zhou HM, Zheng YF, Peng B, Haapasalo M. Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J Endod 2013; 39(2):163–72.

- Silva EJ, Rodrigues C, Vieira VT, Belladonna FG, De-Deus G, Lopes HP. Bending resistance and cyclic fatigue of a new heat-treated reciprocating instrument. Scanning 2016; 38(6):837–41.

- Silva EJNL, Vieira VTL, Gabina TTG, Antunes HDS, Lopes HP, De-Deus G. The impact of using a pneumatic contra-angle device on the lifespan of M-Wire- and Blue-treated instruments. Clin Oral Investig 2019; 23(2):617– 21.

- Thompson SA. An overview of nickel-titanium alloys used in dentistry. Int Endod J 2000; 33(4):297–310.

- Kiefner P, Ban M, De-Deus G. Is the reciprocating movement per se able to improve the cyclic fatigue resistance of instruments? Int Endod J 2014; 47(5):430–6.

- De-Deus G, Moreira EJ, Lopes HP, Elias CN. Extended cyclic fatigue life of F2 ProTaper instruments used in reciprocating movement. Int Endod J 2010; 43(12):1063–8.

- Alcalde MP, Duarte MAH, Bramante CM, de Vasconselos BC, Tanomaru-Filho M, Guerreiro-Tanomaru JM, et al. Cyclic fatigue and torsional strength of three different thermally treated reciprocating nickel-titanium instruments. Clin Oral Investig 2018; 22(4):1865–71.

- Inan U, Keskin C, Sivas Yilmaz Ö, Baş G. Cyclic fatigue of Reciproc Blue and Reciproc instruments exposed to intracanal temperature in simulated severe apical curvature. Clin Oral Investig 2019; 23(5):2077–82.

- Silva EJNL, Vieira VTL, Hecksher F, Dos Santos Oliveira MRS, Dos Santos Antunes H, Moreira EJL. Cyclic fatigue using severely curved canals and torsional resistance of thermally treated reciprocating instruments. Clin Oral Investig 2018; 22(7):2633–8.

- Silva EJNL, Hecksher F, Antunes HDS, De-Deus G, Elias CN, Vieira VTL. Torsional Fatigue Resistance of Blue-treated Reciprocating Instruments. J Endod 2018; 44(6):1038–41.

- Silva EJ, Villarino LS, Vieira VT, Accorsi-Mendonça T, Antunes HD, De-Deus G, et al. Bending Resistance and Cyclic Fatigue Life of Reciproc, Unicone, and WaveOne Reciprocating Instruments. J Endod 2016; 42(12):1789–93.

- de Vasconcelos RA, Murphy S, Carvalho CA, Govindjee RG, Govindjee S, Peters OA. Evidence for Reduced Fatigue Resistance of Contemporary Rotary Instruments Exposed to Body Temperature. J Endod 2016; 42(5):782–7.

- De-Deus G, Leal Vieira VT, Nogueira da Silva EJ, Lopes H, Elias CN, Moreira EJ. Bending resistance and dynamic and static cyclic fatigue life of Reciproc and WaveOne large instruments. J Endod 2014; 40(4):575–9.

- 3630-1 IOfSI. Dental root canal instruments: part 1-files, reamers, barbed broaches, rasps, paste carriers, explorers and cotton broaches. International Organization for Standardization, Geneva: 1992. Available at: https://www.iso.org/standard/9066.html. Accessed Apr 22, 2020.

- Spili P, Parashos P, Messer HH. The impact of instrument fracture on outcome of endodontic treatment. J Endod 2005; 31(12):845–50.

- Pedullà E, Lo Savio F, Boninelli S, Plotino G, Grande NM, La Rosa G, et al. Torsional and Cyclic Fatigue Resistance of a New Nickel-Titanium Instrument Manufactured by Electrical Discharge Machining. J Endod 2016; 42(1):156–9.

- Yao JH, Schwartz SA, Beeson TJ. Cyclic fatigue of three types of rotary nickel-titanium files in a dynamic model. J Endod 2006; 32(1):55–7.

- Keskin C, Inan U, Demiral M, Keleş A. Cyclic Fatigue Resistance of Reciproc Blue, Reciproc, and WaveOne Gold Reciprocating Instruments. J Endod 2017; 43(8):1360–3.

- Plotino G, Grande NM, Cordaro M, Testarelli L, Gambarini G. A review of cyclic fatigue testing of nickel-titanium rotary instruments. J Endod 2009; 35(11):1469–76.

- Silva EJNL, Vieira VTL, Belladonna FG, Zuolo AS, Antunes HDS, Cavalcante DM, et al. Cyclic and Torsional Fatigue Resistance of XP-endo Shaper and TRUShape Instruments. J Endod 2018; 44(1):168–72.

- Arias A, Hejlawy S, Murphy S, de la Macorra JC, Govindjee S, Peters OA. Variable impact by ambient temperature on fatigue resistance of heat-treated nickel titanium instruments. Clin Oral Investig 2019; 23(3):1101–8.

- Arias A, Macorra JC, Govindjee S, Peters OA. Correlation between Temperature-dependent Fatigue Resistance and Differential Scanning Calorimetry Analysis for 2 Contemporary Rotary Instruments. J Endod 2018; 44(4):630–4.

- Alcalde MP, Tanomaru-Filho M, Bramante CM, Duarte MAH, Guerreiro-Tanomaru JM, Camilo-Pinto J, et al. Cyclic and Torsional Fatigue Resistance of Reciprocating Single Files Manufactured by Different Nickel-titanium Alloys. J Endod 2017; 43(7):1186–91.