Multimethod Analysis of Three Rotary Instruments Produced by Electric Discharge Machining Technology

ABSTRACT

Aim: This study aimed to compare three rotary instruments produced by the EDM process with the heat-treated ProTaper Gold system regarding design, metallurgy, mechanical properties and shaping ability. Further details about endodontic instruments and root canal preparation protocols are accessible for you to learn on our course "Evidence-based endodontics: complex histo-analysis and treatment protocols".

Methodology: HyFlex EDM (25/~), Neoniti (25/.06), EDMax (25/.06) and ProTaper Gold (25/.08v) instruments (n=58 per group) were compared regarding design, metallurgy and mechanical performance. Unprepared canal areas were calculated for each system after preparation of mesiobuccal, mesiolingual and distal canals of mandibular molars (15 canals per group) using micro-CT technology. Statistical analyses were performed using One-way anova post-hoc Tukey and Kruskal–Wallis posthoc Dunn's tests (α=5%).

Results: All instruments had asymmetrical blades, no radial lands, no major defects and almost equiatomic nickel/titanium ratios, but different cross-section designs, tip geometries and surface appearances. Although instruments had distinct transformation temperature curves, they showed crystallographic martensitic arrangement at 21°C and mixed austenite plus R-phase at body temperature. Neoniti and HyFlex EDM showed similar results in all mechanical tests (p>.05), while EDMax and ProTaper Gold had similar time to fracture (p=.841), maximum bending load (p=.729), and cutting ability (p=.985). ProTaper Gold showed the highest torque to failure (p<.001) and HyFlex EDM had the lowest buckling resistance (p<.001). Mean percentages of unprepared canal areas ranged from 20.4% to 25.7% in the mesial canals, and from 20.8% to 26.2% in the distal canal, with no statistical differences among systems (p>.05).

Conclusions: Instruments' geometry and phase transformation temperatures influenced the results of the mechanical tests, but not their shaping ability.

INTRODUCTION

Improvements in the nickel–titanium (NiTi) metallurgy allowed the development of a variety of new endodontic instruments with different designs, which ended up in an enhanced efficiency not only in the control of iatrogenic mishaps, such as deviation and perforation but also in the root canal shaping, making it faster, easier and with better clinical outcomes compared with conventional preparation with stainless-steel hand files (Bürklein & Arias, 2022). Even so, NiTi instruments are still susceptible to deformations and/or fractures, an unwanted event that may represent a predictor of persistent apical periodontitis and consequent failure when treating infected teeth (McGuigan et al., 2013; Ng et al., 2011). To overcome these problems, manufacturers have developed several strategies to improve the properties of the NiTi alloy including changes on kinematics, instruments' design and surface treatment (Martins, Martins, et al., 2022). In the last years, manufacturers have also developed different production methods to the traditional grinding method such as twisting, shape-setting, laser-cutting and electric discharge machining (EDM) (Arias & Peters, 2022). Through the process of EDM, instruments are manufactured by a non-contact thermal erosion through controlled sparks that occur between an electrode and a metal workpiece in the presence of a dielectric fluid (Arias & Peters, 2022; Pirani et al., 2016). This process “melts” the surface of the nickel–titanium alloy, partially evaporating small portions of the metal and leaving behind an eroded surface. The instrument is then heat-treated at temperatures between 300 and 600°C for 10min to 5h, before or after ultrasonic cleaning and acid bath (Gavini et al., 2018).

This unique process does not use physical contact for material removal, but the local vaporization of the metal preventing the formation of microcracks, and may optimize the cutting ability, flexibility and cyclic fatigue resistance of rotary instruments (Arias & Peters, 2022; Gavini et al., 2018; Pedullá et al., 2016; Pirani et al., 2016).

The first NiTi rotary instrument launched in the market and manufactured using the EDM process was an orifice opener named Initial (Neolix SAS) (Mallet, 2012). In the following year, the same company launched the Neoniti system (Neolix SAS), a set of rotary instruments also produced by the EDM method (Stanurski, 2013). HyFlex EDM (Coltene/Whaledent) was launched 2 years later (Müller, 2015) and initial studies demonstrated a higher cyclic fatigue resistance compared with other instruments produced with superelastic or martensitic NiTi alloys (Gündoğar & Özyürek, 2017; Silva et al., 2020; Thu et al., 2020). More recently, a multimethod study showed no difference between the mechanical behaviour of HyFlex EDM and Neoniti instruments (Silva et al., 2020). In the current year, the EDMax system (Neolix SAS), another set of rotary instruments produced by the same process, was introduced into the market. However, according to the manufacturer, this system has striking differences compared with Neoniti, including streaked cutting edges, non-rectangular variable parallelogram cross-section with sharp cutting edges, and hardened and abrasive surface. In addition, EDMax instruments are submitted to a heat treatment that results in active blades with blueish colour, in contrast to the yellowish colour of Neoniti and HyFlex EDM instruments. These modifications were implemented to this system aiming to improve their mechanical efficiency and shaping ability; but, thus far, there is no scientific evidence to support this statement. Therefore, this study aimed to use a multimethod approach to evaluate design, metallurgy, mechanical performance and shaping ability of 3 preparation systems manufactured using the EDM process (HyFlex EDM, Neoniti, and EDMax), using the ProTaper Gold system (Dentsply Sirona) as reference for comparison. The null hypothesis tested was that there would be no differences among tested instruments regarding their mechanical properties.

MATERIALS AND METHODS

The manuscript of this laboratory study has been written according to Preferred Reporting Items for Laboratory studies in Endodontology (PRILE) 2021 guidelines (Nagendrababu et al., 2021) (Figure 1). A total of 232 new 25-mm NiTi instruments (58 per group) from HyFlex EDM (25/~), Neoniti (25/0.06), EDMax (25/0.06) and ProTaper Gold (25/0.08v) rotary systems were tested regarding design, metallurgical characteristics and mechanical performance, while 100 instruments (HyFlex EDM [n=20], Neoniti [n=25], EDMax [n=25], and ProTaper Gold [n=30]) were additionally employed to compare the shaping ability of each system in root canals of extracted mandibular molars, using the instrumentation sequence recommended by the manufacturers. Instruments were previously examined under a stereomicroscope (×13.6 magnification; Opmi Pico, Carl Zeiss Surgical) looking for defects that would exclude them from being tested, but none was excluded.

FIGURE 1. PRILE flowchart.

FIGURE 1. PRILE flowchart.

Design

Three new 25-mm instruments per system (n=12) were evaluated under conventional scanning electron micros-copy (SEM) (S-2400, Hitachi) regarding the symmetry of the blade (symmetrical or asymmetrical) (×20 magnification), the tip geometry (active or non-active (×40), the cross-sectional shape (×80) and the presence of surface marks, deformations or defects produced by the manufacturing process (×200).

Metallurgy

The semi-quantitative elemental analysis was carried out in 3 instruments from each tested system to evaluate the ratio of nickel and titanium in the alloy, or the pres-ence of other elements, using a scanning electron microscope (S-2400; Hitachi) equipped with energy-dispersive X-ray spectroscopy (EDS) (Bruker Quantax; Bruker Corporation) set at 20kV and 3.1 A. The analysis was performed in each instrument at a 25-mm distance from a surface area of 400μm2 using dedicated software with ZAF correction (Systat Software Inc.). Differential scanning calorimetry (DSC) method (DSC 204 F1 Phoenix; Netzsch-Gerätebau GmbH) was applied to determine the phase transformation temperatures of the NiTi alloy (ASTM International, 2004). Fragments of 2 to 3mm in length (5–10mg) acquired from the coronal active blade of two instruments from each system were exposed to a chemical etching (25% hydrofluoric acid, 45% nitric acid and 30% distilled water) for 2min and mounted on an aluminium pan inside the DSC device, with an empty pan serving as control. Each thermal cycle was performed under gaseous nitrogen atmosphere at a pace of 10°C/min with temperatures ranging from −150°C to 150°C, and the phase transformation temperatures were analysed by the Netzsch Proteus Thermal Analysis software (Netzsch-Gerätebau GmbH). In each group, the DSC test was performed twice.

Mechanical tests

The mechanical performance of the selected systems was assessed by cyclic fatigue, cutting ability, torsional, bending and buckling resistance tests. Sample sizes were cal-culated based on the highest difference obtained by two instruments after six initial measurements with an alpha-type error of 0.05 and power of 80%. For the time to fracture (Neoniti vs. EDMax; effect size of 0.80), maximum torque(Neoniti vs. EDMax; effect size of 1.0), angle of rotation (Neoniti vs. EDMax; effect size of 0.85), maximum bending load (Neoniti vs. EDMax; effect size of 0.87), buckling resistance (Neoniti vs. EDMax; effect size of 0.54), and cutting ability (Neoniti vs. EDMax; effect size of 0.88) parameters, sample sizes were 5, 4, 5, 5, 10, and 5, respectively. Therefore, a total of 10 instruments per group was defined for each dependent variable.

The cyclic fatigue test followed the methodology reported in a previous study (Martins, Silva, et al., 2022) and was conducted at room temperature in accordance with the recommendations of the American Society for Testing and Materials (ASTM International, 2004) and a current ISO norm proposal (Peters et al., 2020). All instruments were activated at static mode by a torque-controlled motor (VDW Silver; VDW) set at 300 rpm and 1.5N. Fracture was detected by visual and auditory inspection, time to fracture (in seconds) was recorded using a digital chronometer, and the fragment size (in mm) was measured with a digital calliper (resolution of 0.01mm; Mitutoyo) for experimental control. Torsional and bending resistance tests were performed according to international standards (ISO 3630-3631, 2008) to assess the maximum torque (in N.cm), the angle of rotation prior to fracture (in degrees), and the maximum load needed for a 45° displacement of the instrument (in gram/force; gf), respectively. The buckling test was performed according to a previous publication (Lopes et al., 2012). A diagram of load (N) × deformation (mm) was obtained for each instrument and the maximum load needed to induce the elastic displacement of the instrument up to 1 mm was calculated. The cutting efficiency test was done following the methodology proposed by Plotino et al. (2014). Each instrument was powered by an electric motor (Reciproc Silver; VDW GmbH) mounted to a free-falling holder and activated (300 rpm; 3.0N) in direct contact with a Plexiglass block for 1 min. The analysis of the cutting depth in the blocks was performed using a digital calliper (Mitutoyo).

Shaping ability

After approval of this research project by the local Ethics Committee (Protocol CAAE 57369521.9.0000.5283), 20 two-rooted mandibular molars presenting mesial and distal root canals with moderate curvature (Schneider, 1971) and Vertucci's Type IV and I configurations, respectively, were selected. Inclusion criteria also comprised teeth with fully formed apices, no internal resorption, calcification, previous endodontic treatment or root fracture.

All teeth were imaged in a micro-CT device (SkyScan 1174v.2; Bruker-MicroCT) and reconstructed (NRecon v.1.6.9; Bruker-microCT) using standardized parameters, according to a previous study (Silva et al., 2020). Then, information about volume (in mm3), surface area (in mm2) and configurations of mesial and distal root canals (CTAn v.1.14.4; Bruker-microCT), were obtained to create 4 anatomically-matched groups (n=15 canals per group). After conventional access cavity preparation, apical patency was confirmed with a size 10 K-file (Dentsply Sirona Endodontics) and glide path performed using a size 15 K-file (Dentsply Sirona Endodontics) up o the working length (WL), established 1mm from the apical foramen. One set of each tested system was used to prepare 1 tooth (3 canals) according to the following protocols:

HyFlex EDM system: After coronal flaring (instrument 25/.12; 500 rpm, 2.5N.cm), instruments 10/.05 (300 rpm 1.8N.cm) and 25/~(500 rpm, 2.5N.cm) were used up to the WL.

Neoniti system: After coronal flaring (instrument 25/.12; 300 rpm, 1.5N.cm), instruments 15/.03 (300 rpm, 1.5N.cm), 20/.06 (300 rpm, 1.5N.cm) and 25/.06 (300 rpm, 1.5N.cm) were used up to the WL.

EDMax system: after coronal flaring (instrument 20/.10; 500 rpm, 1.5N.cm), instruments 15/.03 (500 rpm, 1.5N.cm), 20/.06 (500 rpm, 1.5N.cm), and 25/.06 (500 rpm, 1.5N.cm) were used up to the WL.

ProTaper Gold system: After coronal flaring (instrument SX 19/.04v; 300 rpm, 5.0N.cm), instruments S1 (18/.02v; 300 rpm, 1.5N.cm), S2 (20/.04v; 300 rpm, 1.5N.cm), F1 (20/.07v; 300 rpm, 1.5N.cm), and F2 (25/.08v; 300 rpm, 3.0N.cm) were used up to the WL.

Considering that the physiological diameter of distal canals of mandibular molars at the apical third has been reported to range from 0.39 and 0.46 mm (Wolf et al., 2017), these canals were further enlarged using the size 40 instrument of each system (HyFlex EDM 40/.04, Neoniti 40/.04, EDMax 40/.04 and ProTaper Gold 40/.06v).

Instruments were activated by an electric motor (VDW Silver; VDW) and used in a slow in-and-out pecking motion of about 3 mm amplitude with light pressure to the apical direction. After three pecking motions, the instrument was removed from the canal and cleaned. The WL was reached after 3 waves of instrumentation. Each instrument was used in one tooth and discarded. Irrigation was performed with a total of 15 mL of 2.5% NaOCl per canal, followed by a final rinse with 5 mL of 17% EDTA (3 min) and 5 mL of distilled water using a syringe fitted with a 30-G NaviTip needle (Ultradent) positioned 2 mm from the WL. All procedures were performed by an experienced operator under magnification (×12.5; Zeiss OPMI Pico). After preparation, the canals were slightly dried with paper points and a final scan and reconstruction were performed using the previously mentioned parameters. Datasets acquired before and after preparation were co-registered and the root canals were evaluated regarding volume, surface area and unprepared surface areas. The latter was determined by the formula (Au/Ab)*100, where Au and Ab represent the unprepared area and the canal area before preparation, respectively.

There are additional details about endodontic treatment in complex cases that you can obtain in course "Endodontics: from classic protocols to extreme"

Statistical analysis

The Shapiro–Wilk and Lilliefors tests were used to verify the normality of the data. Depending on data distribution, results were summarized as mean (standard deviation) or median (interquartile range) values. One-way anova and post-hoc Tukey tests were carried out to compare time to failure, angle of rotation, bending resistance, buckling resistance, cutting ability, volume, surface area and untouched canal areas, while Kruskal–Wallis and post-hoc Dunn's tests with Bonferroni correction to adjust for multiple comparisons were used to compare the maximum torque to failure. Significance level was set at 5% (SPSS v25.0 for Windows; SPSS Inc.).

RESULTS

Design

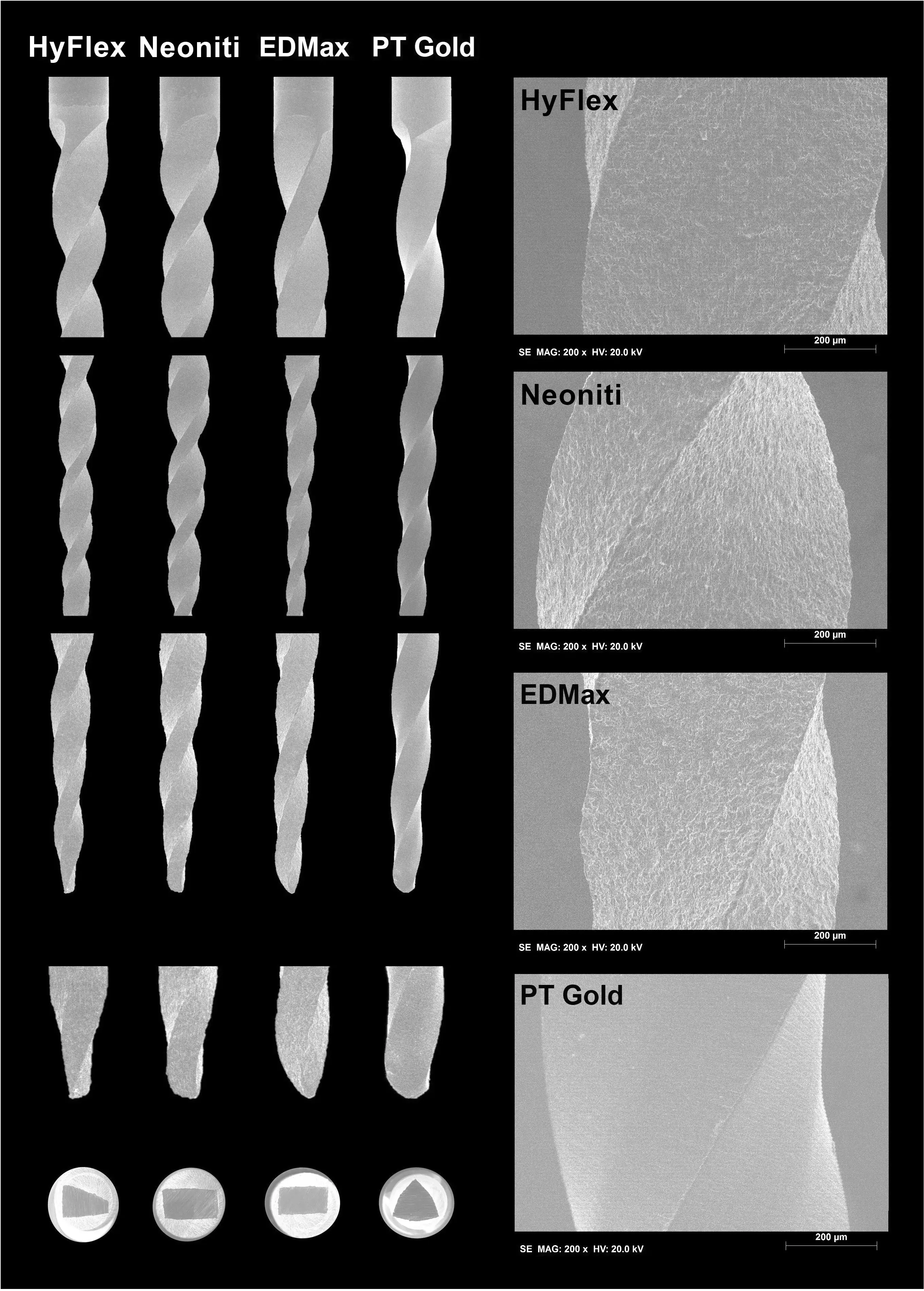

SEM analyses revealed that all instruments had asymmetrical blades with no radial lands. The cross-section designs of EDMax (non-rectangular parallelogram with a slight positive rake angle), Neoniti (parallelogram with a rectangle-like shape) and ProTaper Gold (convex triangular) were symmetrical, while HyFlex EDM was asymmetrical (trapezoidal/irregular convex hexagon). EDMax, Neoniti and ProTaper Gold instruments showed a slightly rounding tip-transition angle, while HyFlex EDM showed a different tip feature, more active. HyFlex EDM, Neoniti and EDMax instruments had regularly distributed craters, a typical isotropic surface observed in materials submitted to the electrical discharge machining process. In contrast, ProTaper Gold displayed a very distinct surface finish with marks resulting from the manufacturing process (grinding). Only small defects, such as barbs in the cutting edge, were observed in all instruments (Figure 2)

FIGURE 2. SEM analyses of the active blade, cross-section design, tip geometry, and surface finishing of tested instruments. All instruments had asymmetrical blades, no radial lands, and different cross-section designs and tip geometries. HyFlex EDM, Neoniti and EDMax instruments had isotropic surface with regularly distributed crater, while ProTaper Gold had parallel griding marks.

FIGURE 2. SEM analyses of the active blade, cross-section design, tip geometry, and surface finishing of tested instruments. All instruments had asymmetrical blades, no radial lands, and different cross-section designs and tip geometries. HyFlex EDM, Neoniti and EDMax instruments had isotropic surface with regularly distributed crater, while ProTaper Gold had parallel griding marks.

Metallurgy

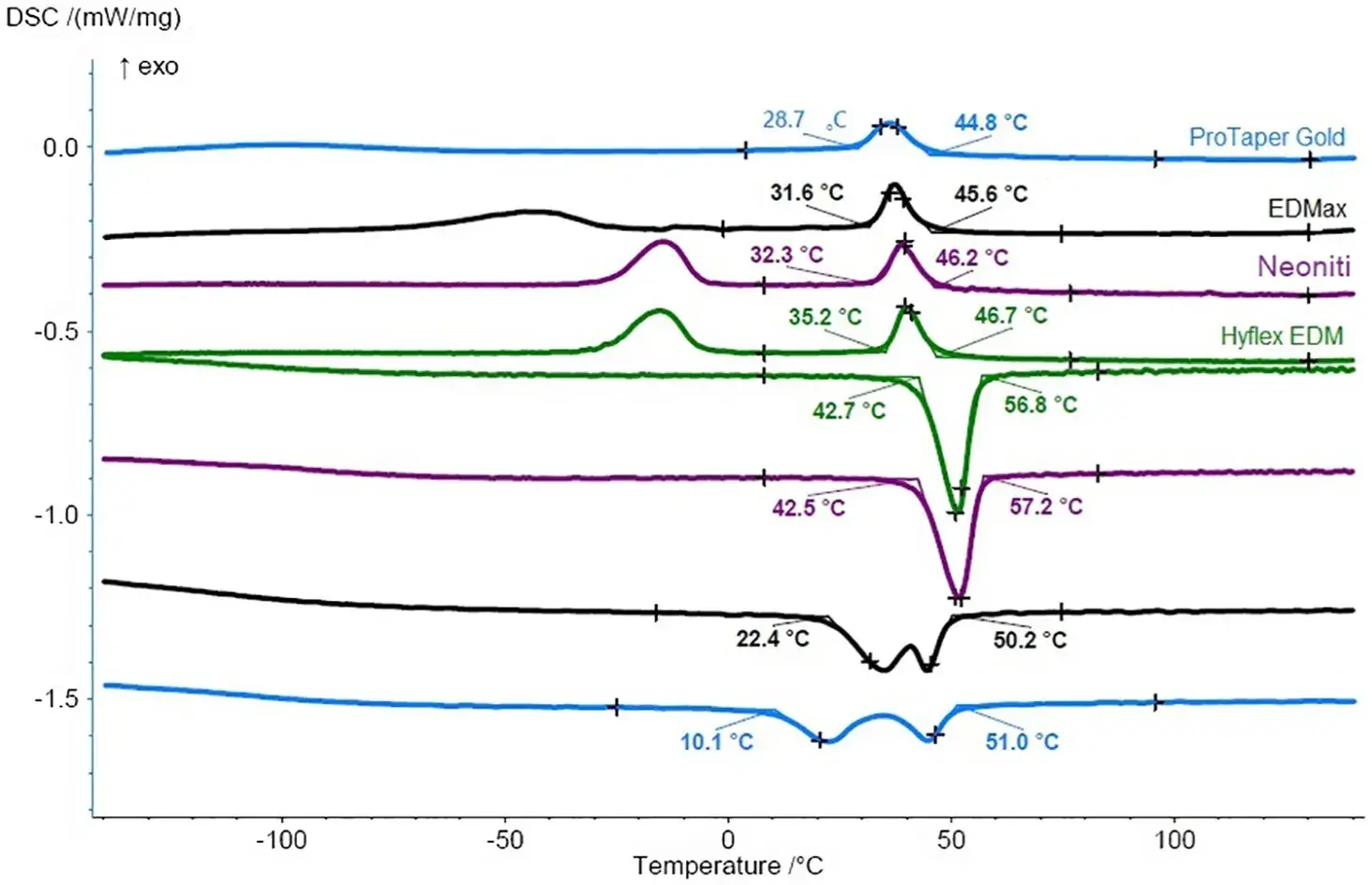

EDS/SEM analyses revealed a nearly equiatomic nickel/titanium ratio in HyFlex EDM (1.062), Neoniti (1.065), EDMax (1.028) and ProTaper Gold (1.001) instruments, without any other traceable metal element. DCS analyses showed distinct transformation temperature curves (Figure 3). HyFlex EDM and Neoniti had comparable results on cooling R-phase to martensite B19’ transformation, which was different from EDMax and ProTaper Gold. HyFlex EDM and Neoniti also showed an almost perfectly overlapped martensitic B19’ and R-phase transformations to austenite-B2 on heating, while the other instruments had a double peak transformation. The cooling R-phase start (Rs) and R-phase finishing (Rf) transformation temperatures were distinct among instruments, ranging from 44.8°C (ProTaper Gold) to 46.7°C (HyFlex EDM), and from 28.7°C (ProTaper Gold) to 35.2°C (HyFlex EDM), respectively. All tested instruments had a crystallographic R-phase arrangement at test temperature (21°C) and a mixed austenite plus R-phase at body temperature. At heating, the lowest and highest Austenite start (As) temperatures were noted with ProTaper Gold (10.1°C) and HyFlex EDM (42.7°C), respectively, while the highest Austenite finish (Af) tem-peratures were observed in HyFlex EDM (56.8°C) and Neoniti (57.2°C) instrument.

FIGURE 3. DSC charts showing the phase transformation temperatures at cooling on top (reads from right to left) and at heating on bottom (from left to right). The cooling R-phase start (Rs) and R-phase finishing (Rf) transformation temperatures were distinct among instruments. At heating, the lowest and highest Austenite start (As) temperatures were noted with ProTaper Gold and HyFlex EDM, respectively, while the highest Austenite finish (Af) temperatures were observed in HyFlex EDM and Neoniti instruments.

FIGURE 3. DSC charts showing the phase transformation temperatures at cooling on top (reads from right to left) and at heating on bottom (from left to right). The cooling R-phase start (Rs) and R-phase finishing (Rf) transformation temperatures were distinct among instruments. At heating, the lowest and highest Austenite start (As) temperatures were noted with ProTaper Gold and HyFlex EDM, respectively, while the highest Austenite finish (Af) temperatures were observed in HyFlex EDM and Neoniti instruments.

Mechanical performance

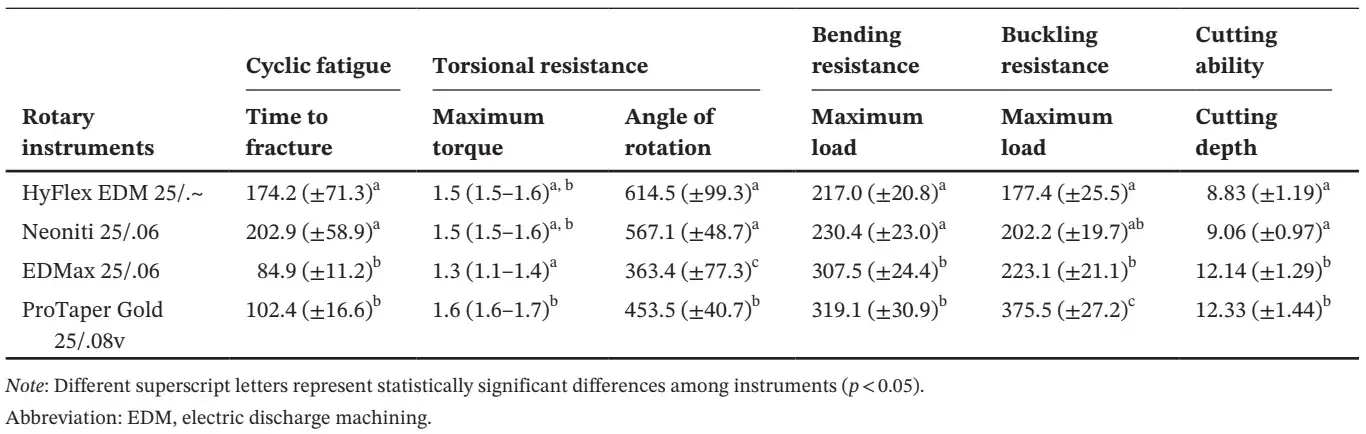

Neoniti and HyFlex EDM showed similar results in all mechanical tests (p>.05), while EDMax and ProTaper Gold had similar time to fracture (p=.841), maximum bending load (p=0.729), and cutting depth (p=0.985). The highest time to fracture and angle of rotation was observed in Neoniti and HyFlex EDM instruments (p<.001), while EDMax and ProTaper Gold presented the highest bending load (lower flexibility) and cutting depth (p<.001). ProTaper Gold showed the highest torque to failure (p<.001) and HyFlex EDM had the lowest buckling resistance (p<.001) (Table 1)

TABLE 1. Mean (standard deviation) or median [interquartile range] results of time to fracture (s), maximum torque (N.cm), angle of rotation (°), maximum load (gf), and cutting depth (mm) parameters obtained after testing four different rotary instruments

Shaping ability

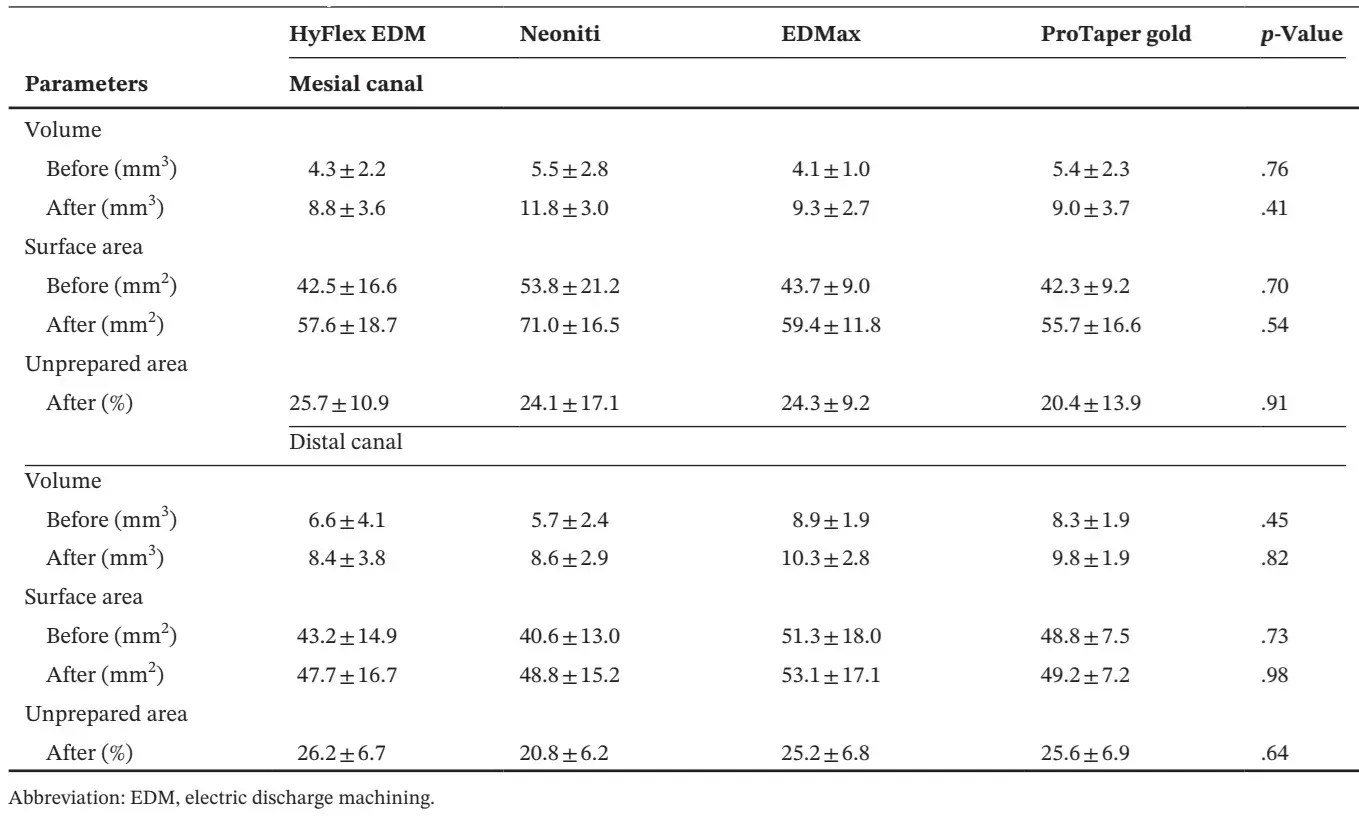

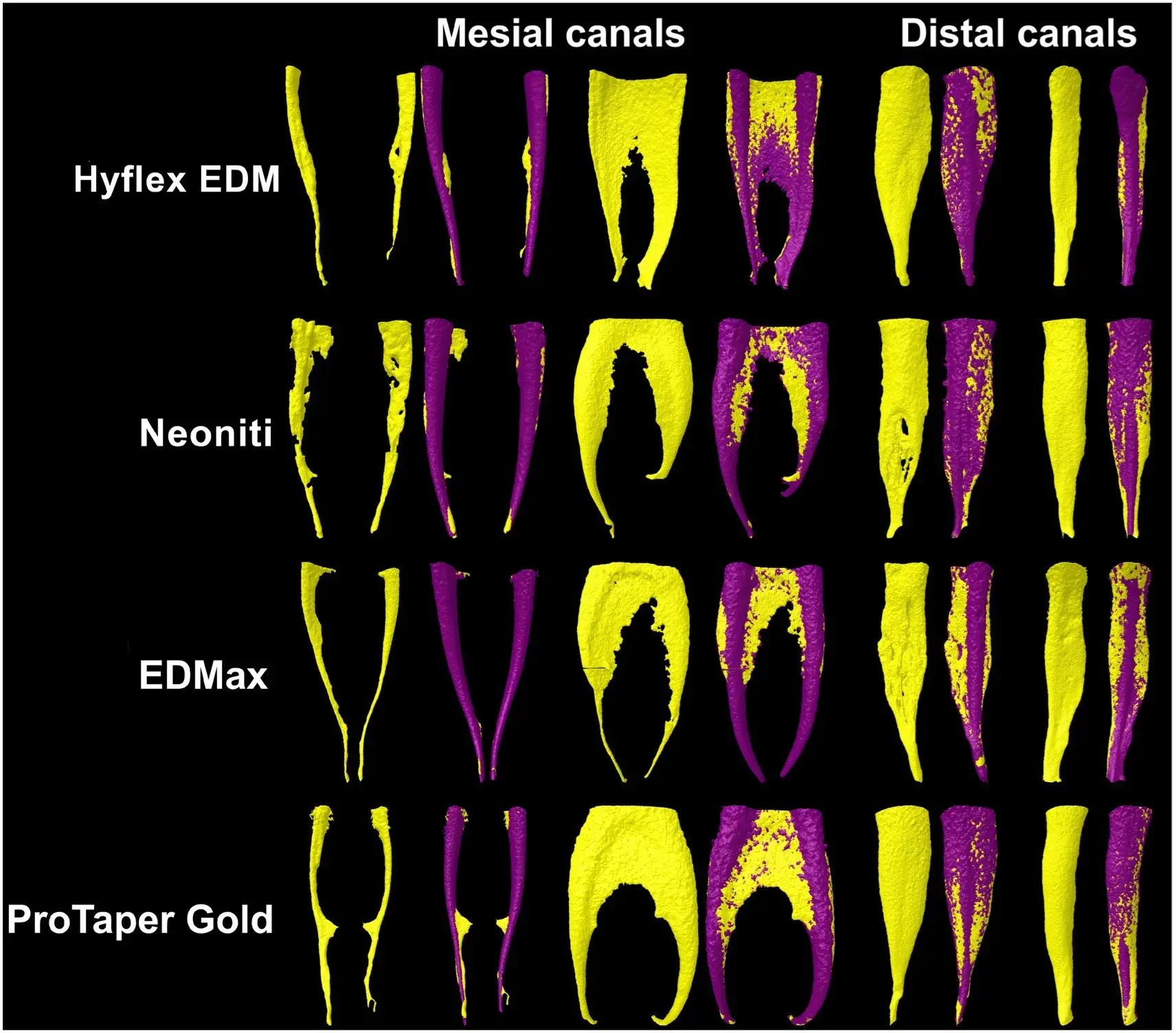

The homogeneity of groups regarding volume and surface area of mesial and distal canals was confirmed (p>.05). Mean percentages of unprepared canal areas ranged from 20.4% to 25.7% in the mesial canals, and from 20.8% to 26.2% in the distal canal, with no statistical differences among tested instruments (p>.05) (Table 2, Figure 4).

TABLE 2. Pre- and post-operative parameters evaluated in both mesial and distal root canals of mandibular molars after preparation with four different NiTi systems.

FIGURE 4. Micro-CT analyses. Representative 3D models of 8 mesial and 8 distal root canal systems of mandibular molars before (yellow colour) and after (purple colour) preparation with HyFlex EDM, Neoniti, EDMax, and ProTaper Gold rotary canal systems. In mesial and distal canals, the mean percentage of unprepared canal walls ranged from 20.4% to 25.7% and from 20.8% to 26.2%, respectively.

FIGURE 4. Micro-CT analyses. Representative 3D models of 8 mesial and 8 distal root canal systems of mandibular molars before (yellow colour) and after (purple colour) preparation with HyFlex EDM, Neoniti, EDMax, and ProTaper Gold rotary canal systems. In mesial and distal canals, the mean percentage of unprepared canal walls ranged from 20.4% to 25.7% and from 20.8% to 26.2%, respectively.

DISCUSSION

This study presents original results comparing the mechanical behaviour of three rotary instruments produced by the EDM process with the well-known ProTaper Gold system regarding cyclic fatigue, cutting ability, torsional, bending and buckling resistance. A comprehensive understanding of the results, however, was only possible because of the further evaluation of their overall designs, surface finishings and metal alloy crystal-lographic arrangements, performed in accordance with international guidelines (ASTM International, 2004; ISO 3630-3631, 2008) or well-established and validated methodologies (Lopes et al., 2012; Plotino et al., 2014; Versiani et al., 2018). This multimethod approach avoids the phenomenon of ‘knowledge compartmentalization’ while provides comprehensive knowledge of each method by taking advantage of their strength and minimizing their weaknesses in order to improve the internal validation of the research (Hunter & Brewer, 2015). In this study, Neoniti and HyFlex EDM showed similar results in all mechanical tests (Table 1), corroborating a previous study (Silva et al., 2020) in which these two instruments were also compared regarding cyclic fatigue and torsional resistance. These findings might be explained considering that, although they might present small differences in their cross-sectional designs, these instruments have comparable dimensions (tip and taper), quality of manufacturing (Figure 2), and metallurgical properties, as demonstrated by EDS and DSC assays (Figure 3). On the other hand, results revealed differences in their mechanical properties compared to EDMax and ProTaper Gold instruments (Table 1), and the null hypothesis was rejected. It may be assumed that alloy composition had no impact on the mechanical performance of instruments, considering that all systems were made with similar amounts of nickel and titanium elements, without traces of other metals. On the other hand, the combination of the overall geometry, evaluated by stereomicroscopy and SEM, and the alloy crystallographic arrangement, determined by the DSC phase transformation temperature analysis, can partially explain almost all mechanical findings.

During the preparation of curved canals, NiTi instruments are submitted to consecutive cycles of tension and compression that can reduce their life cycle by creating surface microcracks that may propagate, a phenomenon that can be simulated by the cyclic fatigue test, a method that uses a well-defined set of experimental conditions. In these same clinical conditions, the flexibility, assessed by the bending resistance test, is also important as it allows instruments to keep the original canal pathway while performing its enlargement. In addition, during root canal preparation, sometimes it is necessary to apply a light pressure along the axis of the instrument to allow its progression toward the apex. This property is assessed by the buckling test, a method developed to evaluate the ability of an instrument to sustain a compressive load in the direction of its own axis (Martins, Martins, et al., 2022).

In this study, cyclic fatigue and flexibility of HyFlex EDM and Neoniti were similar, but higher than ProTaper Gold and EDMax (Table 1). The main variables that affect the results of these tests are the metallurgical properties and the size of instruments (Martins, Martins, et al., 2022) and, therefore, the results of cyclic fatigue and bending resistance tests can be explained by the small dimensions of Neoniti and HyFlex EDM (25/.06), the lowest Austenite start temperature of the ProTaper Gold (10.1°C) (Figure 3), and by the EDM process, which usually produces high flexible instruments (Pedullá et al., 2016; Pirani et al., 2016), corroborating the results of previous studies (Kaval et al., 2016; Silva et al., 2020). On the other hand, although EDMax was also produced by the EDM method and had similar dimensions (Figure 1), it showed less time to fracture and flexibility than Neoniti and HyFlex EDM (Table 1), a finding that can be explained by differences in their thermal treatments (Figure 3). The new thermal treatment applied to the EDMax changed its transformation temperature curve by reducing its Austenite start temperature to 22.4°C when compared to Neoniti (42.5°C) and HyFlex EDM (42.7°C) (Figure 3), indicating that its alloy converts to austenite closed to the test temperature (21°C), makes it less flexible and relatively stiffer than Neoniti and HyFlex EDM. These differences in the heating curve (Figure 3) also help to explain the higher buckling resistance of EDMax compared to Neoniti and HyFlex EDM, while the largest dimensions of ProTaper Gold justifies its highest buckling resistance values (Table 1).

One of the main objectives of NiTi endodontic instruments is the removal of infected dentine during root canal shaping procedures (Martins, Martins, et al., 2022). Thus, during the progression of the instrument to apical direction, its cutting efficiency, a property related to the capacity of an instrument to advance into the root canal and to provide lateral cut, is of utmost importance. This property depends on some features including metallurgy, surface treatment, cross-sectional design, sharpness of flute and tip design. In this study, however, the lowest cutting depth of Neoniti and HyFlex EDM (Table 1) can be explained by their phase transformation temperatures. Because of their high Austenitic start temperatures (Figure 3), these instruments present more martensitic behaviour than EDMax and ProTaper Gold. When the instrument is in its martensite form, it is soft and ductile and can easily be deformed, which may affect its efficiency for cutting (Arias & Peters, 2022), as observed herein.

The torsional strength is determined by the maximum torque before fracture, a characteristic that is relevant to prepare narrow or constricted root canals, and the angle of rotation, related to the capacity to sustain deformation before fracture under a torsional stress (Martins, Martins, et al., 2022). This property is highly relevant during the mechanical action of cutting dentine, as it is the main mechanism that may lead instruments to fracture (Sattapan et al., 2000). This mechanical property may be affected by several factors including the thermomechanical process applied during manufacturing, the cross-sectional design, the alloy composition and the dimension of the instrument (Martins et al., 2021; Martins, Martins, et al., 2022). In this test, however, the apical 3mm of the instrument is locked in a chuck and rotated at a constant pace until fracture (ISO 3630-3631, 2008), a methodological aspect that may partially explain the present results. In general, large-sized instruments at this specific level tend to sustain higher torque (Martins, Martins, et al., 2022), which justifies the highest maximum torque observed in the ProTaper Gold instrument (Table 1). Likewise, similarities of HyFlex, Neoniti and EDMax instruments in terms not only on their manufacturing process (EDM) but also in their size and surface finishing at this level, were the main reasons to explain their comparable results.

The angle of rotation represents the maximum rotation that an instrument would be able to support before its fracture by torsion. Higher values on this parameter are usually observed in large instruments, since they tend to sustain high torque, as well as, in heat-treated instruments because of the increased deformation ability resulting from their high ductility and flexibility (Ninan & Berzins, 2013). In this study, highest angles of rotation were observed in HyFlex and Neoniti instruments possibly because of their higher flexibility as a result of their distinct transformation-temperature curves (Figure 3).

Although many studies rely on mechanical parameters to assess the performance of rotary NiTi systems, a more comprehensive understanding should also include the assessment of their effectiveness in preparing the root canal system. Therefore, a multimethod approach combining the results of different mechanical tests and the shaping ability of different NiTi systems would be of benefit for a better interpretation of their performance and, consequently, a more precise translation of preclinical findings to guide the clinical use (Silva et al., 2020). In this study, tested systems were compared regarding the percentage of untouched canal walls left after the preparation of mesial and distal root canals of mandibular molars and evaluated using the gold standard micro-CT technology. This parameter has a high clinical relevance since untouched canal areas may harbour residual bacteria and serve as a potential cause of persistent infection, which ultimately may lead to post-treatment disease (Arias & Peters, 2022; Bürklein & Arias, 2022). In fact, the present findings are an ever-present condition in clinical practice since no preparation system was able to touch all root canal walls (Gagliardi et al., 2015; Martins et al., 2021; Versiani et al., 2013, 2018). As a consequence of this suboptimal performance, it is important to emphasize that current canal shaping protocols are still largely dependent on the action of irrigation procedures for intracanal disinfection.

Preliminary efforts were made to ensure comparability of the groups by anatomically matching the specimens based on morphometric parameters of the root canal system including configuration, volume and surface area. This process reduces the anatomical bias that usually confound the outcomes in this type of study and creates a reliable baseline, enhancing the internal validity of the study (Versiani et al., 2013). While the metallurgical and design dissimilarities of tested instruments were clearly reflected in the results of the mechanical tests, micro-CT evaluation revealed no difference among systems in the percentage of unprepared areas (Figure 4), with values ranging from 20.4% to 25.7% in the mesial canals and from 20.8% to 26.2% in the distal canal (Table 2). These findings corroborate previous micro-CT studies (Gagliardi et al., 2015; Martins et al., 2021; Silva et al., 2020; Stringheta et al., 2019; Versiani et al., 2018) and might be attributed to the previous balancing of groups regarding their internal morphology and the inherent anatomical complexity of the root canal system of mandibular molars (Martins et al., 2021). The analysis of centring ability (canal transportation/centroid shift) was not performed in the pres-ent study because the selection criteria included only root canals with moderate curvature and tested instruments had a very high flexibility, demonstrated by their transformation temperature curves (Figure 3) and bending load results (Table 1). In these conditions, it is unlikely that clinical relevant changes in the original canal curvature could be noticed, as previously reported (Gagliardi et al., 2015; Silva et al., 2023; Silva, Lima, et al., 2022; Silva, Martins, et al., 2022). Therefore, future studies are suggested to compare the ability of instruments produced by EDM technology to prepare severely curved canals.

The main strength of this study was the use of a multimethod research approach that allowed the interconnection of the results and a better understanding of the influence of each factor on the overall performance of tested systems, which highlight the importance of assessing several variables and not relying on one single aspect of the instrument behaviour. As limitations, the real dimensions of instruments were not assessed and other tests, such as microhardness and electron probe x-ray microanalysis (EPMA), could have been also used in this multimethod protocol, which are recommended to be included in further studies.

CONCLUSIONS

This multimethod research allowed to obtain noteworthy information of the main set instruments of three rotary systems produced by electric discharge machine technology through different perspectives in order to compare their mechanical performance and shaping efficiency with the well-known heat-treated ProTaper Gold system. Overall, it was observed that instruments' geometry and phase transformation temperatures influenced the results of the mechanical tests, but not their shaping ability.

You have the opportunity to gather more in-depth information about endodontic treatment in different clinical cases in our course "Endodontics 3.0".

List of authors:

Emmanuel J. N. L. Silva, Natasha C. Ajuz, Jorge N. R. Martins, Bernardo R. Antunes, Carolina O. Lima, Victor T. L. Vieira, Francisco Manuel Braz-Fernandes, Marco A. Versiani

References

Arias, A. & Peters, O.A. (2022) Present status and future directions: canal shaping. International Endodontic Journal, 55(Suppl 3), 637–655.

ASTM International. (2004) ASTM F2004–17: standard test method for transformation temperature of nickel-titanium alloys by thermal analysis. West Conshohocken, PA: American Society for Testing and Materials.

Bürklein, S. & Arias, A. (2022) Effectiveness of root canal instrumentation for the treatment of apical periodontitis: a systematic review and meta-analysis. International Endodontic Journal. (Epub ahead of print).

Gagliardi, J., Versiani, M.A., de Sousa-Neto, M.D., Plazas-Garzon, A. & Basrani, B. (2015) Evaluation of the shaping characteristics of ProTaper gold, ProTaper NEXT, and ProTaper universal in curved canals. Journal of Endodontics, 41, 1718–1724.

Gavini, G., Santos, M.D., Caldeira, C.L., Machado, M.E.L., Freire, L.G., Iglecias, E.F. et al. (2018) Nickel-titanium instruments in endodontics: a concise review of the state of the art. Brazilian Oral Research, 32, e67.

Gündoğar, M. & Özyürek, T. (2017) Cyclic fatigue resistance of OneShape, HyFlex EDM, WaveOne gold, and Reciproc blue nickel-titanium instruments. Journal of Endodontics, 43, 1192–1196.

Hunter, A. & Brewer, J.D. (2015) Designing multimethod research. In: Hesse-Biber, S. & Johnson, R.B. (Eds.) The Oxford handbook of multimethod and mixed methods research inquiry. Oxford, UK: Oxford University Press.

ISO 3630-3631. (2008) Dentistry—root canal instruments—part 1: general requirements and test methods. Geneva, Switzerland: International Organization for Standardization.

Kaval, M.E., Çapar, I.D. & Ertas, H. (2016) Evaluation of the cyclic fatigue and torsional tesistance of novel nickel-titanium rotary files with various alloy properties. Journal of Endodontics, 42, 1840–1843.

Lopes, H.P., Elias, C.N., Mangelli, M., Lopes, W.S.P., Amaral, G., Souza, L.C. et al. (2012) Buckling resistance of pathfinding endodontic instruments. Journal of Endodontics, 38, 402–404.

Mallet, J.P. (2012) Initial Neolix: L'innovation française. Endo Tribune, 4, 19.

Martins, J.N.R., Martins, R.F., Braz Fernandes, F.M. & Silva, E. (2022) What meaningful information are the instruments mechanical testing giving us? A comprehensive review. Journal of Endodontics, 48, 985–1004.

Martins, J.N.R., Silva, E., Marques, D. et al. (2022) Design, metallurgical features, and mechanical behaviour of NiTi endodontic instruments from five different heat-treated rotary systems. Materials, 15, 1009.

Martins, J.N.R., Silva, E.J.N.L., Marques, D., Belladonna, F., Simões-Carvalho, M., Vieira, V.T.L. et al. (2021) Design, metallurgical features, mechanical performance and canal preparation of six reciprocating instruments. International Endodontic Journal, 54, 1623–1637.

McGuigan, M.B., Louca, C. & Duncan, H.F. (2013) The impact of fractured endodontic instruments on treatment outcome. British Dental Journal, 214, 285–289.

Müller, B. (2015) Ashort history of the NiTi file revolution. Roots, 11, 42–46.

Nagendrababu, V., Murray, P.E., Ordinola-Zapata, R., Peters, O.A., Rôças, I.N., Siqueira, J.F., Jr. et al. (2021) PRILE 2021 guidelines for reporting laboratory studies in endodontology: explanation and elaboration. International Endodontic Journal, 54, 1491–1515.

Ng, Y.L., Mann, V. & Gulabivala, K. (2011) A prospective study of the factors affecting outcomes of nonsurgical root canal treatment: part 1: periapical health. International Endodontic Journal, 44, 583–609.

Ninan, E. & Berzins, D.W. (2013) Torsion and bending properties of shape memory and superelastic nickel-titanium rotary instruments. Journal of Endodontics, 39, 101–104.

Pedullá, E., Lo Savio, F., Boninelli, S. et al. (2016) Torsional and cyclic fatigue resistance of a new nickel-titanium instrument manufactured by electrical discharge machining. Journal of Endodontics, 42, 156–159.

Peters, O.A., Arias, A. & Choi, A. (2020) Mechanical properties of a novel nickel-titanium root canal instrument: stationary and dynamic tests. Journal of Endodontics, 46, 994–1001.

Pirani, C., Iacono, F., Generali, L., Sassatelli, P., Nucci, C., Lusvarghi, L. et al. (2016) HyFlex EDM: superficial features, metallurgical analysis and fatigue resistance of innovative electro discharge machined NiTi rotary instruments. International Endodontic Journal, 49, 483–493.

Plotino, G., Giansiracusa Rubini, A., Grande, N.M., Testarelli, L. & Gambarini, G. (2014) Cutting efficiency of Reciproc and waveOne reciprocating instruments. Journal of Endodontics, 40, 1228–1230.

Sattapan, B., Nervo, G.J., Palamara, J.E. & Messer, H.H. (2000) Defects in rotary nickel-titanium files after clinical use. Journal of Endodontics, 26, 161–165.

Schneider, S.W. (1971) A comparison of canal preparations in straight and curved root canals. Oral Surgery Oral Medicine Oral Pathology, 32, 271–275.

Silva, E.J.N.L., Lima, C.O., Barbosa, A.F.A., Lopes, R.T., Sassone, L.M. & Versiani, M.A. (2022) The impact of TruNatomy and ProTaper gold instruments on the preservation of the periradicular dentin and on the enlargement of the apical canal of mandibular molars. Journal of Endodontics, 48, 650–658.

Silva, E.J.N.L., Martins, J.N.R., Ajuz, N.C., Antunes, H.S., Vieira, V.T.L., Braz Fernandes, F.M. et al. (2022) A multimethod assessment of a new customized heat-treated nickel-titanium rotary file system. Materials, 15, 5288.

Silva, E.J.N.L., Martins, J.N.R., Ajuz, N.C., dos Santos Antunes, H., Vieira, V.T.L., Braz-Fernandes, F.M. et al. (2023) Design, metallurgy, mechanical properties, and shaping ability of 3 heat-treated reciprocating systems: a multimethod investigation. Clinical Oral Investigations. (Epub ahead of print).

Silva, E.J.N.L., Martins, J.N.R., Lima, C.O., Vieira, V.T.L., Braz Fernandes, F.M., De-Deus, G. et al. (2020) Mechanical tests, metallurgical characterization, and shaping ability of nickel-titanium rotary instruments: a multimethod research. Journal of Endodontics, 46, 1485–1494.

Stanurski, A. (2013) A new manufacturing process for new NiTi rotary files. Roots, 9, 2013.

Stringheta, C.P., Bueno, C.E.S., Kato, A.S., Freire, L.G., Iglecias, E.F., Santos, M. et al. (2019) Micro-computed tomographic evaluation of the shaping ability of four instrumentation systems in curved root canals. International Endodontic Journal, 52, 908–916.

Thu, M., Ebihara, A., Maki, K., Miki, N. & Okiji, T. (2020) Cyclic fatigue resistance of rotary and reciprocating nickel-titanium instruments subjected to static and dynamic tests. Journal of Endodontics, 46, 1752–1757.

Versiani, M.A., Carvalho, K.K.T., Mazzi-Chaves, J.F. & Sousa-Neto, M.D. (2018) Micro-computed tomographic evaluation of the shaping ability of XP-endo shaper, iRaCe, and EdgeFile systems in long oval-shaped canals. Journal of Endodontics, 44, 489–495.

Versiani, M.A., Steier, L., De-Deus, G., Tassani, S., Pécora, J.D. & Sousa-Neto, M.D. (2013) Micro–computed tomography study of oval-shaped canals prepared with the self-adjusting file, Reciproc, WaveOne, and Protaper universal systems. Journal of Endodontics, 39, 1060–1066.

Wolf, T.G., Paque, F., Sven Patyna, M., Willershausen, B. & Briseno-Marroquin, B. (2017) Three-dimensional analysis of the physiological foramen geometry of maxillary and mandibular molars by means of micro-CT. International Journal of Oral Science, 9, 151–157.