Design principles and characteristics of orthodontic appliance elements

Machine translation

Original article is written in RU language (link to read it).

All orthodontic appliances are a combination of certain structural elements, each of which is necessary to perform its specific function. Some help fix the apparatus on the teeth, others are directly necessary for the displacement of teeth, and still others are auxiliary parts, without which the orthodontic apparatus cannot be assembled into a single system.

Learn more about orthodontic appliances in the online course Orthodontic Appliances. Morphological changes during orthodontic treatment. Clinical cases .

When planning the design of an orthodontic appliance, it is important to follow the following rules:

If the patient has a bad habit (thumb sucking, pencil chewing, lip biting), the design of the orthodontic appliance should include elements that can relieve the patient from this bad habit.

The design features and adaptations of the device are designed to ensure the development of sufficient force and its application in the right direction.

Considering the direction of application of force and the task at hand, the device must provide stable support and acceptable fixation in the patient’s oral cavity.

If there are anomalies in the position of the teeth and a lack of space in the dental arch, when planning the design it is important to select elements that will help solve these problems.

If there is a natural obstacle in the path of tooth movement, the design features of the future apparatus should include devices that will help free up space for tooth movement.

Figure 1. Adams clasp.

Fixing the device

In order to quickly and efficiently perform their functions, removable devices for bite correction must have a reliable fixation in the patient’s mouth. The main device for fixing the orthodontic apparatus is the clasp.

The metal from which the clasps are made should not be subject to oxidation under the influence of oral fluid and have high spring properties. The most popular material for making clasps is stainless steel, which is produced in the form of wire 0.6-1.2 mm in diameter.

The clasp design includes the following components:

shoulder - a section of the clasp that presses the apparatus to the surface of the tooth;

the body is the direct working part of the clasp;

process – necessary for fixation on the plastic base.

Figure 2. Vestibular arch.

Classification of clasps

The entire variety of clasps is divided into the following three categories:

Clasps, the shoulder of which is adjacent to the crown of the tooth along the entire plane. Representatives of this group: cast, curved, tape clasps.

Clasps, the shoulder of which is linearly adjacent to the crown of the tooth. Representatives of this group: frame, round, Jackson crossover.

Clasps, the shoulder of which is pointwise adjacent to the crown of the tooth. Representatives of this group: Schwartz, Adams, button, arrow-shaped clasps.

Round clasp

The simplest design has a single-arm round retaining clasp, and it has also gained the most popularity. It consists of several main fragments: the appendage, the body, and the shoulder.

Clasp shoulder

It should be located below the contact point of the crown, covering the surface of the crown as tightly as possible, provide a springing effect during the movement of the device, and not put pressure on the teeth at rest. The carefully polished and slightly rounded tip of the shoulder should be located on the opposite surface of the tooth crown at the height of the contact point.

Clasp body

It is located tightly pressed to the side surface of the crown, located in the equator area, oriented towards the missing teeth. When the body is expressed, the clasp is more elastic in relation to the supporting tooth.

Clasp extension

It must be positioned strictly parallel to the bone crest inside the plastic base of the device.

Figure 3. Orthodontic plates.

Manufacturing

To make a round clasp, you can use standard blanks, which are produced with a diameter of 0.5-1.2 mm. But if you don’t have any blanks on hand, you can easily make a round clasp yourself from steel orthodontic wire. The clasp is bent using crampon pliers or round-nose pliers with constant monitoring on the plaster model.

The arm of the clasp is bent with round pliers in such a way as to clasp the vestibular part of the crown as tightly as possible, repeating the line of the neck behind the equator, while not allowing it to touch the gum. At the contact point, not reaching the cutting edge or occlusal surface, the following bend is made, forming the body of the clasp, located on the lateral surface in the area of the equator of the crown. At almost a right angle to the second, a third bend is made, which forms a process located along the bone crest inside the plastic base.

Adams clasp

This clasp is considered the most effective and versatile, superior to the round one in its fixing properties. It is suitable for both single standing teeth and continuous dental arches. Thanks to its pinpoint location on the vestibular surface of the crown in the gingival region, the Adams clasp ensures good fixation of the entire apparatus.

Clasp blanks can be purchased, but then they will have to be adjusted individually depending on the specific clinical case.

Types of Adams clasps:

With one fixation claw – suitable for patients with low crowns if the bite height is significantly reduced. In the distal section, the shoulder is arched according to the principle of a round clasp. It does not interfere with closing the mouth.

For two central incisors - this is an Adams clasp, which has a longer arm. The locking ridges cover the lateral edges of both incisors.

A two-/three-link clasp is designed for several teeth at once.

Multi-link Adams clasp - its design involves the number of fixing protrusions corresponding to the number of teeth and two processes for fixation in the base.

Adams clasp, equipped with special extensions necessary for applying and fixing rubber rings.

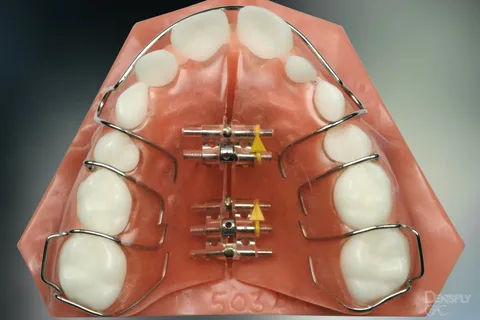

Figure 4. Orthodontic plate with screw.

Vestibular arches

This structural element is necessary to stabilize the apparatus itself, as well as to shift the anterior teeth. Vestibular arches are made of steel wire 0.6-0.9 mm in diameter.

The vestibular arch with semi-straight bends is a structure consisting of a central part, two symmetrical semicircular bends, which is fixed by two processes.

The central part of the arch fixes the removable appliance, and in the process of compressing the bends it ensures the transfer of pressure to the teeth in the oral direction. The bends are made semicircular to prevent deformation of the arc during compression.

An arch with M-shaped bends is a design that is used when it is necessary to have a palatal inclination of canines located outside the dentition. The M-shaped bend is low and wide; it should not have a traumatic effect on the transitional fold. The wire for this arc is chosen thin, no more than 0.6-0.7 mm.

Orthodontic springs

These structural devices as part of orthodontic appliances are used to move single teeth or groups of teeth in any direction.

The following types of springs are distinguished:

to move the tooth in a vertical plane;

to move the tooth in the sagittal plane;

to shift the tooth in the transversal plane;

to rotate around its own axis.

The material used is orthodontic wire 0.2-1.2 mm in diameter.

The spring design consists of the following parts:

free end, transfers pressure to the teeth being moved,

working or active part,

the fixing process is located in a plastic base.

Figure 5. Activation of the orthodontic appliance.

The spring force is determined by the following factors:

physical and mechanical characteristics of the metal;

The diameter of the wire;

length of the free end of the spring;

number and width of bends;

degree of activation.

The larger the diameter of the steel wire and the shorter the length of the acting arm, the higher the spring force will be. The force of the spring gradually decreases, this is due to the loss of elastic qualities, the degree of activation of the spring and the features of its design.

The following types of springs are distinguished:

Capable of putting pressure on individual teeth. Representatives of this group: finger-shaped, serpentine, with a curl.

Capable of putting pressure on a group of teeth. Representatives of this group: eight-shaped, oval.

Capable of narrowing or expanding the dentition. Representatives of this group: Koller, Coffin springs.

Finally, it is worth noting that in addition to the springs that the technician makes independently in the laboratory, there are also ready-made standard spirals and coiled springs, which can be immediately placed in the orthodontic apparatus. If it is necessary to correct anomalies in the position of the teeth, flip hooks and levers that are bent from wire or cut from steel plates are also used.

About modern methods of manufacturing orthodontic appliances at the webinar Removable and non-removable orthodontic appliances: milling vs printing .