Comparative Analysis of Reciprocating and Flat-Side Heat-Treated Rotary Single-File Systems: Design, Metallurgical Characteristics, and Mechanical Performance

ABSTRACT

Aim: To compare two flat-side single-file rotary instruments with three single-file reciprocating systems through a multimethod assessment. There are additional details about modern protocols of endodontic treatment that you can gain in our course "What's new in endodontics: from anesthesia to obturation".

Methodology: A total of 290 new NiTi single-file rotary (AF F One Blue 25/0.06 and Platinum V.EU 25/0.06) and reciprocating (One Files Blue R25, Reciproc Blue R25, Reciproc R25) instruments were selected, carefully examined for any major deformations, and evaluated regarding their macroscopic and microscopic design, nickel and titanium elements ratio, phase transformation temperatures, and mechanical performance (time/rotation to fracture, maximum torque, angle of rotation, microhardness, maximum bending, and buckling strengths). One-way anova post hoc Tukey, T-test, and nonparametric Mood's median tests were used for statistical comparisons (α=5%).

Results: Tested instruments had identical blade counts and near-identical helical angles of approximately 24° (rotary instruments) and 151° (reciprocating instruments). The flat-side analysis revealed a few inconsistencies, such as discontinuity segments, different orientations, and gaps in the homogeneity of the bluish colour. Microscopically, flat-side instruments exhibited blade discontinuity and an incomplete S-shaped cross-section. The surface finish was smoother for One Files Blue and more irregular for both rotary instruments. There were distinct phase transformation temperatures amongst all instruments. All heat-treated instruments were in R-phase arrangement, and Reciproc was in R-phase plus austenite at test temperature (20°C). Compared with the reciprocating instruments, both flat-side instruments exhibited lower results in the cyclic fatigue tests using two different clockwise kinematics, maximum torque, angle of rotation, and maximum buckling strength (p<.05). The rotary systems also exhibited low flexibility (p<.05). AF F One Blue had the lowest microhardness, whilst Reciproc had the highest value.

Conclusion: This multimethod investigation revealed that the flat-side rotary instruments underperformed the reciprocating instruments regarding cyclic fatigue (with two different clockwise kinematics), maximum torque, angle of rotation, maximum buckling strength, and flexibility. Manufacturing inconsistencies were also observed in some of the flat-side instruments, including discontinuity segments, different orientations, and in the homogeneity of their bluish colour given by the heat treatment.

INTRODUCTION

The primary objectives of root canal mechanical preparation procedures are to eliminate the canal content and establish a disinfected canal space, which is crucial for enhancing the success rate of the endodontic treatment (Hülsmann et al., 2005). In addition to advancements in the effectiveness of these procedures, there have been efforts to simplify and optimize the workflow for clinicians and improve the patient experience. The use of a single nickel–titanium (NiTi) instrument for fully shaping the entire root canal space is an example of a technique that has simplified the endodontic workflow and reduced the risk of biological cross-contamination whilst ensuring high-quality treatment outcomes. This concept was first introduced by Yared (2008) and involves the use of reciprocating movements, which alternate clockwise and counter-clockwise, along with slow pecking motions and minimal apical pressure. Since then, the reciprocating movement has gained global acceptance as a viable option for clinicians, and there are now numerous reciprocating systems available on the market (Puentes et al., 2017).

Strong evidence supports this technique, with studies demonstrating its superior cyclic fatigue strength (De-Deus et al., 2010; Lee et al., 2013), lower incidence of instrument fracture and plastic NiTi deformation (Plotino et al., 2015), prolonged lifespan of instruments (Ferreira et al., 2017), and reduced occurrence of ledging and treatment time (Hamid et al., 2018) compared with continuous rotary movement.

Although single-file reciprocating systems have several advantages, they also have some drawbacks, including the need for a dedicated motor capable of developing the kinematic motion and the compaction of large amounts of debris within anatomical irregularities during the enlargement of the root canal space (Robinson et al., 2013). Furthermore, it is worth noting the large tapers of most single-file reciprocating systems currently available on the market. Excessive removal of dentine during root canal preparation, particularly with the use of large taper single-file reciprocating systems, can significantly compromise the fracture resistance of the tooth, especially under certain circumstances. This is a critical concern, as it can make the tooth more prone to fracture due to the structural loss incurred during the shaping phase of endodontic treatment.

In an attempt to address the previously mentioned drawbacks, a new concept was introduced with the development of flat-side rotary instruments made of proprietary heat-treated NiTi alloy, such as the AF F One Blue (Fanta Dental Material Co.) and Platinum V.EU (UDG). These instruments have a modified S-shaped cross-sectional design, an inactive tip, and a unique flat surface and are used in continuous rotation motion. According to the manufacturers (Bondent, 2023; Fanta Dental, 2023a, 2023b), they offer several advantages over traditional instruments since the flat cross-section design reduces the instrument's metal mass, providing greater flexibility and cyclic fatigue. This design is also supossed to result in increased fatigue lifespan and reduced blade engagement, whilst the vertical blades could sweep debris from the flutes to the relieving area for superior debris removal and better cleaning ability. Based on these features, the manufacturers, distributors, and key opinion leaders claim that these instruments are suitable for single-file technique to prepare the root canal to its full working length based on the canal width, following a proper glide path preparation (Fanta Dental, 2023b).

Previous research has compared the first launched AF F One single-file NiTi rotary system (size 25, 0.06 taper; Fanta Dental Material Co.) that is made of a proprietary AF-R wire technology to various rotary and reciprocating systems. These studies showed that AF F One instruments had lower cyclic fatigue resistance than 2Shape instrument after clinical usage (Ubaed & Bakr, 2022), produced more debris but better cleaning ability than One Shape and OneCurve systems (Mogahed et al., 2021), had better shaping ability than a prototype instrument in simulated canals (Di Nardo et al., 2020), were less effective than certain reciprocating systems in removing calcium silicate-based sealer (Madarati et al., 2023) and in eliminating Enterococcus faecalis biofilm from infected root canals (Hamed et al., 2022), but showed improved resistance to flexural fatigue compared with a prototype instrument (Gambarini et al., 2019). These preliminary findings indicate that using flat design instruments instead of other market-available options may not offer the advantages claimed by manufacturers, and further research is necessary to assess their mechanical performance. Thus, this study aimed to compare the design, metallurgical characteristics, and mechanical performance of AF F One Blue (Fanta Dental Material Co.) and Platinum V.EU (UDG) flat-side single-file rotary instruments with three single-file reciprocating systems [One Files Blue (Flydent), Reciproc Blue (VDW), and Reciproc (VDW)].

The null hypothesis posited that there were no differences in mechanical behaviour amongst instruments.

MATERIALS AND METHODS

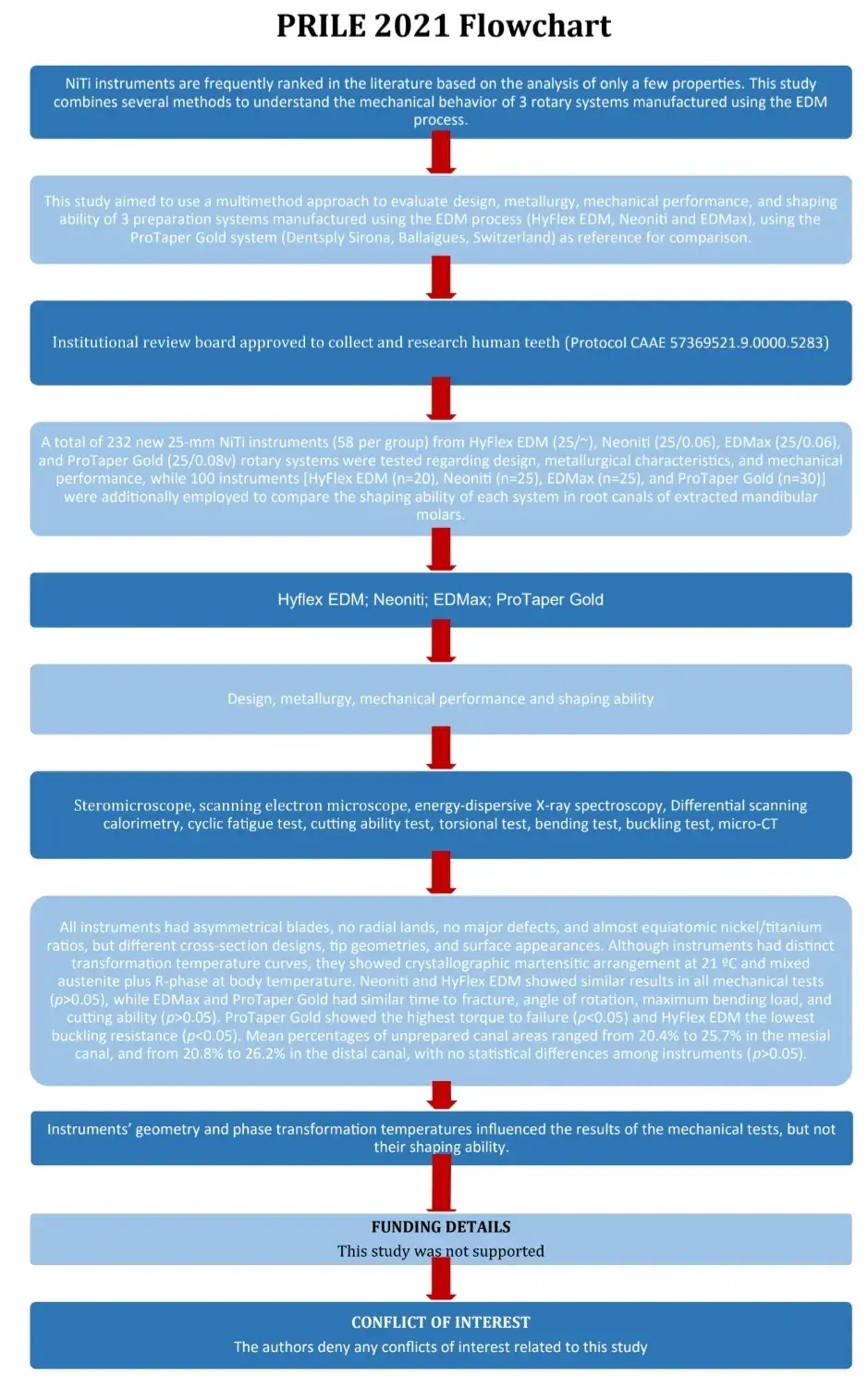

The present manuscript is being reported according to Preferred Reporting Items for Laboratory studies in Endodontology (PRILE) 2021 guidelines (Nagendrababu et al., 2021; Figure 1).

FIGURE 1 PRILE (2021) flowchart (Nagendrababu et al., 2021).

FIGURE 1 PRILE (2021) flowchart (Nagendrababu et al., 2021).

Sample selection

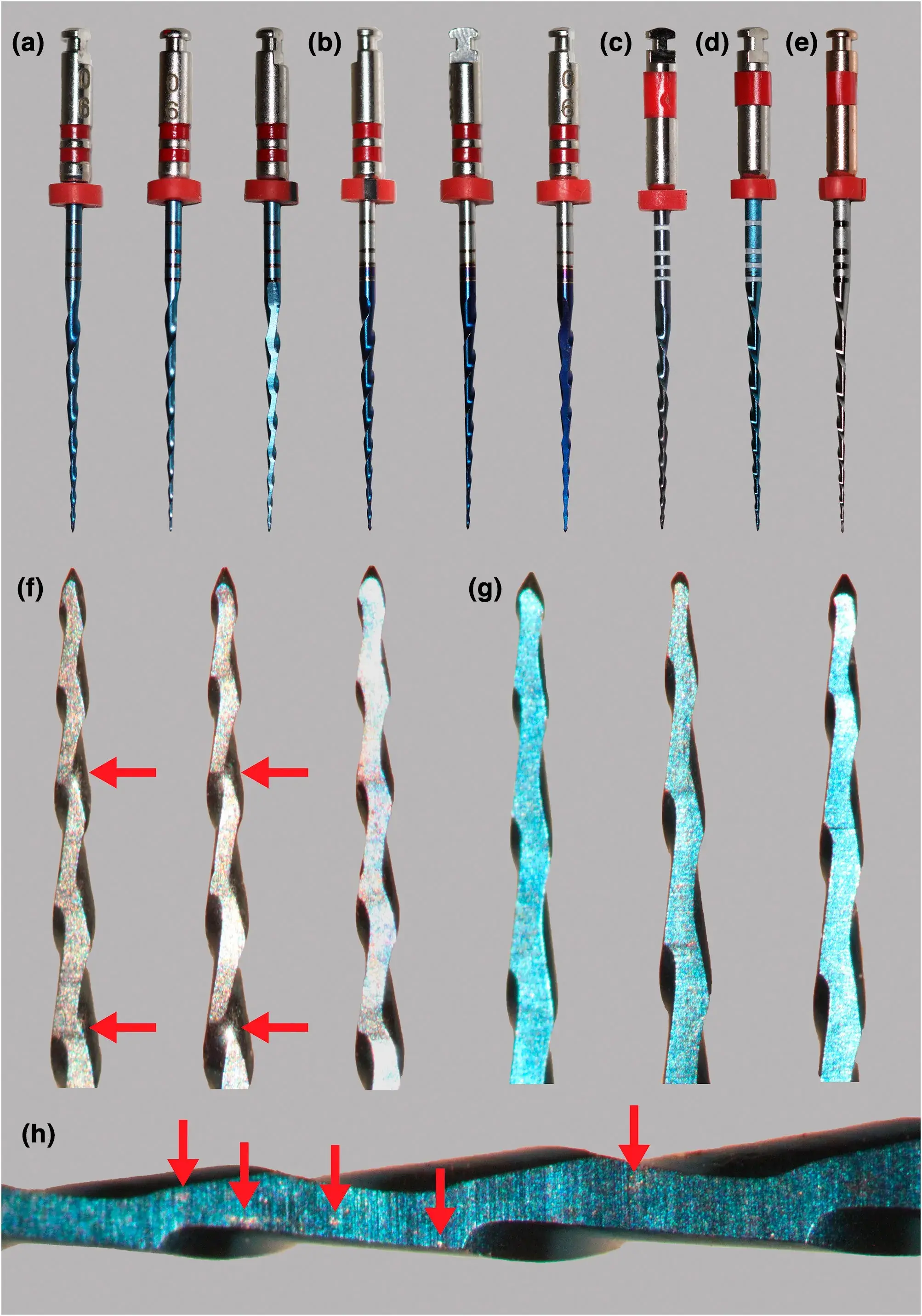

A total of 290 new 25-mm NiTi single-file rotary [AF F One Blue 25/0.06 (Fanta) and Platinum V.EU 25/0.06 (UDG)] and reciprocating [One Files Blue R25 (Flydent), Reciproc Blue R25 (VDW), and Reciproc R25 (VDW)] systems were randomly selected (Figure 2a–e) and carefully examined for any major deformations under a dental microscope at ×13.6 magnification (OPMI Pico; Carl Zeiss Surgical) before testing, and none were excluded from the study.

FIGURE 2 Macroscopic design analyses of tested systems. Different views of (a) AF F One Blue (size 25, 0.06 taper) and (b) Platinum V.EU (size 25, 0.06 taper) instruments showing their asymmetrical blades due to the presence of the flat side, as well as (c) One Files Blue R25, (d) Reciproc Blue R25, and (e) Reciproc R25 reciprocating instruments. The analysis of flat side of (f) AF F One Blue and (g) Platinum V.EU instruments showed that the flat surfaces were machining in different orientations resulting in instruments with different shapes and dimensions in the same blister pack, with (f) discontinuity in some segments of the active blade (arrows). Additionally, (h) a close-up of the Platinum V.EU instrument revealed gaps in the homogeneity of the bluish colour given by the heat treatment (arrows).

FIGURE 2 Macroscopic design analyses of tested systems. Different views of (a) AF F One Blue (size 25, 0.06 taper) and (b) Platinum V.EU (size 25, 0.06 taper) instruments showing their asymmetrical blades due to the presence of the flat side, as well as (c) One Files Blue R25, (d) Reciproc Blue R25, and (e) Reciproc R25 reciprocating instruments. The analysis of flat side of (f) AF F One Blue and (g) Platinum V.EU instruments showed that the flat surfaces were machining in different orientations resulting in instruments with different shapes and dimensions in the same blister pack, with (f) discontinuity in some segments of the active blade (arrows). Additionally, (h) a close-up of the Platinum V.EU instrument revealed gaps in the homogeneity of the bluish colour given by the heat treatment (arrows).

Design

Six instruments from each system were randomly selected and examined under a dental microscope (Opmi Pico) at ×13.6 magnification with a Canon EOS 500D camera (Canon) to document the following characteristics: (i) the number of active blades; (ii) the helical angle based on the average measurements of the six most coronal angles of the active blade; (iii) standardization of the flat side and its positioning; and (iv) the homogeneity of surfaces, particularly the bluish colour due to heat treatment. Subsequently, the instruments were mounted on a file holder and evaluated using a conventional scanning electron microscope (SEM) (S-2400, Hitachi) to inspect the (i) spiral geometry (symmetrical or asymmetrical); (ii) cross-sectional shape; (iii) tip design (active or non-active); (iv) presence and types of surface marks due to the machined production process; and (v) any minor manufacturer irregularities.

Metallurgical characteristics

The metallurgical characteristics were evaluated using energy-dispersive X-ray spectroscopy (EDS) and differential scanning calorimetry (DSC). For the semi-quantitative element analysis, three instruments per group were examined using a SEM (Carl Zeiss Microscopy GmbH) equipped with an Inca X-act EDS detector (Oxford Instruments NanoAnalysis). All acquisitions were performed using a 60-s lifetime (approximately 30% death time), 20 kV, and 3.1A, covering a surface area of 500 μm ×400 μm with ZAF correction. The results were analysed using dedicated software (Microanalysis Suite v.4.14 software; Oxford Instruments NanoAnalysis) to extract the percentages of titanium, nickel, or any other metallic component. The DSC analysis was conducted in accordance with ASTM guidelines (ASTM:F2004–17, 2004). A 3- to 5-mm fragment was extracted from the blade of the instrument and treated with a chemical etching bath consisting of a mixture of 25% hydrofluoric acid, 45% nitric acid, and 30% distilled water for approximately 2 min. The specimens were subsequently cleaned with distilled water and mounted in an aluminium pan, with an empty pan serving as a control. The thermal cycles ranged from −150°C to 150°C, with heating and cooling variations conducted at a rate of 10°C per minute under a nitrogen (N2) atmosphere (DSC 204 F1 Phoenix; Netzsch-Gerätebau GmbH).

The phase transformation temperature results were analysed using the Netzsch Proteus Thermal Analysis software (Netzsch-Gerätebau GmbH). The tests were conducted twice in each group to confirm the results.

Mechanical performance

The mechanical performance of tested systems was assessed by cyclic fatigue, torsional, bending, buckling, and microhardness testing. The optimal sample size for each parameter was determined based on the greatest difference observed between two instruments in the initial six tests. Considering an alpha of 0.05 and 80% power, a sample size of seven specimens was determined for time to fracture under oscillatory asymmetrical motion (Platinum V.EU vs One Files Blue; effect size 235.0±136.7), maximum torque (Platinum V.EU vs One Files Blue; 1.13±0.67), angle of rotation (AF F One Blue vs Reciproc Blue; 178.2±105.9), and maximum buckling load (Platinum V.EU vs Reciproc; 1.25±0.71). A sample size of 6 was determined for the maximum bending load (Platinum V.EU vs Reciproc Blue; 125.9±69.1). Consequently, 10 instruments per group were included in the final sample for each dependent variable. To ensure standardization across tests, all evaluations were performed at room temperature (20°C) in accordance with ASTM F2516 for tension testing of nickel–titanium superelastic alloys (ASTM:F2516-07, 2007).

The cyclic fatigue strength was assessed on a severely curved stainless-steel tube-shaped artificial canal fixed in position on a custom-made solid structure, with a 6mm radius and 86 degrees of curvature, where the position of maximum stress was located 7mm from the canal terminus. The instruments were activated using different operation modes and speeds as per the manufacturers' instructions using the endodontic motor E-connect S (Eighteeth). Specifically, the Reciproc, Reciproc Blue, and One Files Blue were activated using a counter-clockwise reciprocation movement (REC) mode, whilst the AF F One Blue and Platinum V.EU were activated using a clockwise continuous rotation (CW) mode. The AF F One Blue and Platinum V.EU were also tested using the clockwise oscillatory asymmetric motion with equivalent angles of rotation to the reciprocating instruments in an attempt to allow a comparison with the cyclic fatigue results of reciprocating instruments. The tests were conducted on a stationary mode, using a lubricant (glycerin) to avoid in-terferences inside the artificial canal. The moment of instrument breakage was noted both audibly and visually, and the time (in seconds) was recorded using a digital chronometer. For the rotation motion testing, the number of rotations to fracture was also calculated, by multi-plying the rotational speed by the time (in seconds) until fracture occurred. The experimental setup followed the guidelines proposed for a revised ISO 3630-1 norm (Peters et al., 2020).

The ISO 3630-3631 specification (ISO3630-3631, 2008) was followed for both torsional strength and bending tests. For torsion testing, the instruments were mounted in a straight position on a torsiometer TT100 (Odeme Dental Research) with their apical 3-mm clamped. The torsionmeter was activated in a 2rpm constant pace in the clockwise direction for the AF F One Blue and Platinum V.EU and in the counter-clockwise direction for the Reciproc, Reciproc Blue, and One Files Blue, until fracture occurred. The maximum torque (N.cm) sustained before fracture and the angle of rotation (°) were recorded. For bending tests, the instruments were mounted by their grip in the file holder of a universal testing machine (Instron Corporation 4502; series no H3307), with their apical tip pointing down at a 45° angle to the floor plane and in a straight position, whilst their apical 3mm was attached to a wire linked to the testing machine cell. A load of 20N was applied at a constant speed of 15mm per minute until the instrument reached a 45° displacement. The maximum load at the end of the test was recorded in gram/force.

The buckling tests were performed using a 1 kN load cell equipped universal testing machine (Instron Corporation 4502; series no H3307). The instruments were oriented perpendicular to the floor with their grip secured to the testing machine head, and the tip pointing downward and stabilized on a small slot in a stainless-steel testing base (Lopes et al., 2012). The test involved applying a compressive load of 1mm per minute in the axial direction of the instrument, from the grip to the tip, until a lateral displacement of 1mm was reached. The maximum buckling load was measured in Newtons.

The microhardness testing involved marking indentations in each tested instrument using a Vickers Hardness tester (Duramin; Struers Inc.). The sample size was determined by comparing the largest difference between two different instruments, based on the initial five indentations performed in each instrument. With a power of 80%, an alpha of 0.05, and an effect size of 78.60±45.78 (Reciproc vs. One Files Blue), a total of seven indentations were required. Therefore, a final sample size of 15 indentations (five indentations in three instruments per group) was used. Each specimen was prepared according to ASTM guidelines (ASTM:E92-17, 2017) and fixed to an acrylic block before being subjected to microhardness testing. Indentations were made using a diamond penetrator with a press load of 100 gf for 15 s (De-Deus et al., 2017). The outcomes were recorded as Hardness Vickers Number (HVN) at ×40 magnification.

Statistical analysis

The results of the dependent variables were reported as means and standard deviations, as well as medians and interquartile ranges. The time to fracture and maximum buckling load parameters showed a non-Gaussian distribution (Shapiro–Wilk test, p<.05) and were therefore analysed using the nonparametric Mood's median test. Maximum torque, angle of rotation, maximum bending load, and microhardness were analysed using one-way anova and post hoc Tukey test. The time and number of rotations to fracture under rotation mode were compared using the T-test. The significance level was set at 5% (SPSS v.22 for Windows; IBM SPSS Statistics).

RESULTS

Design

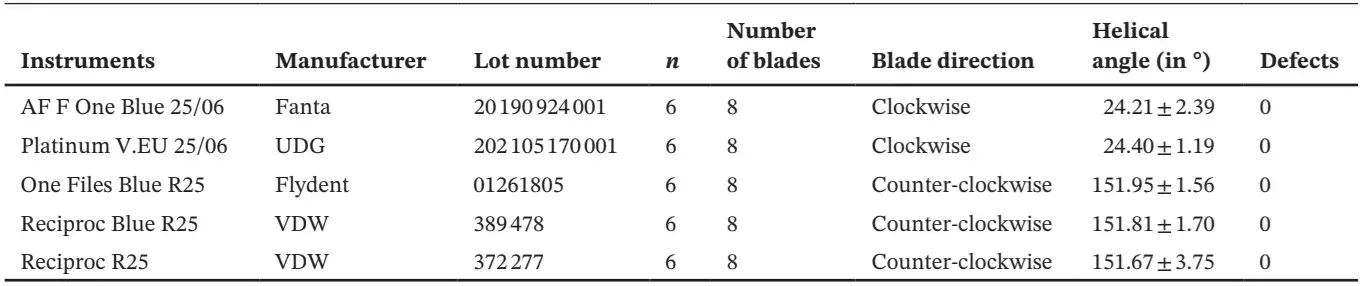

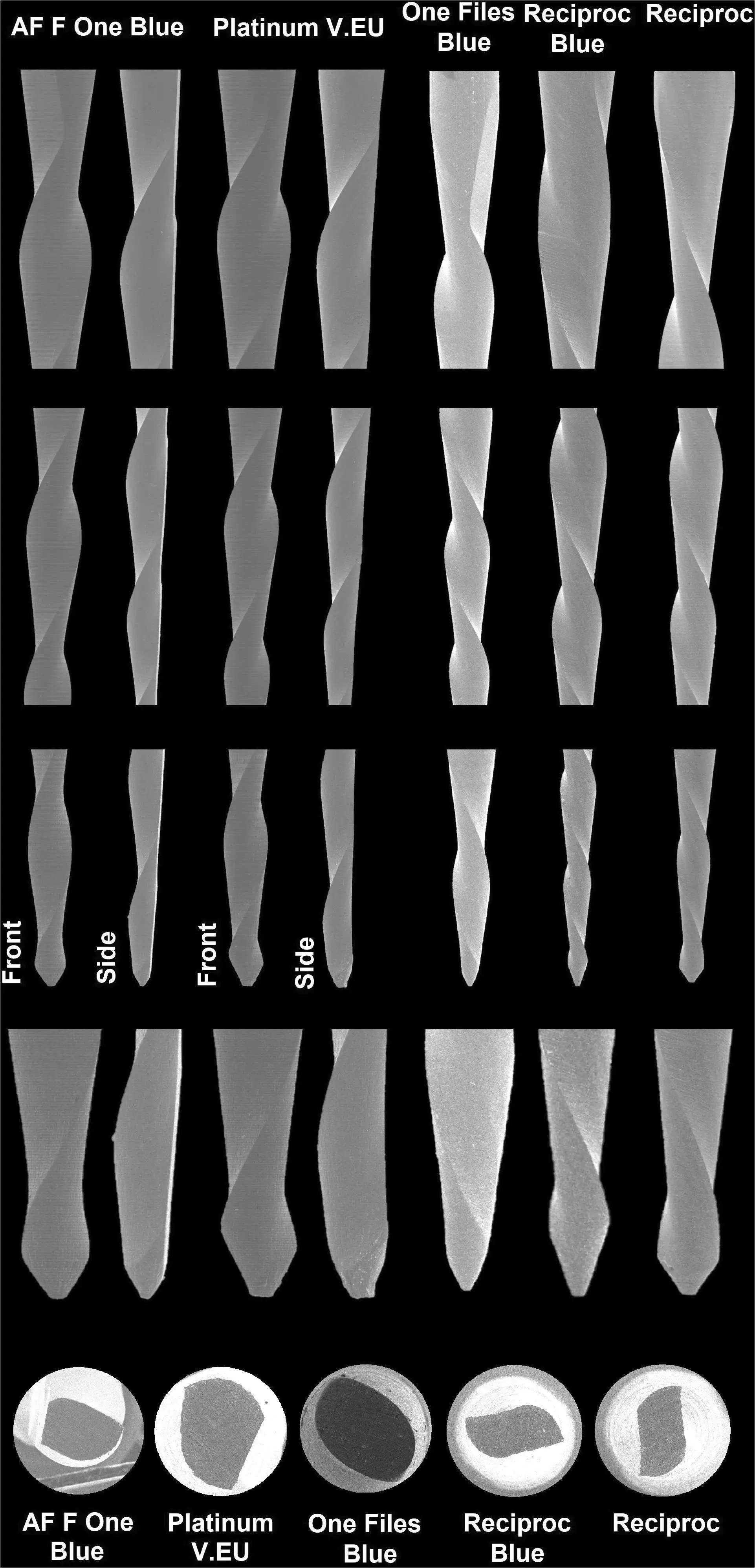

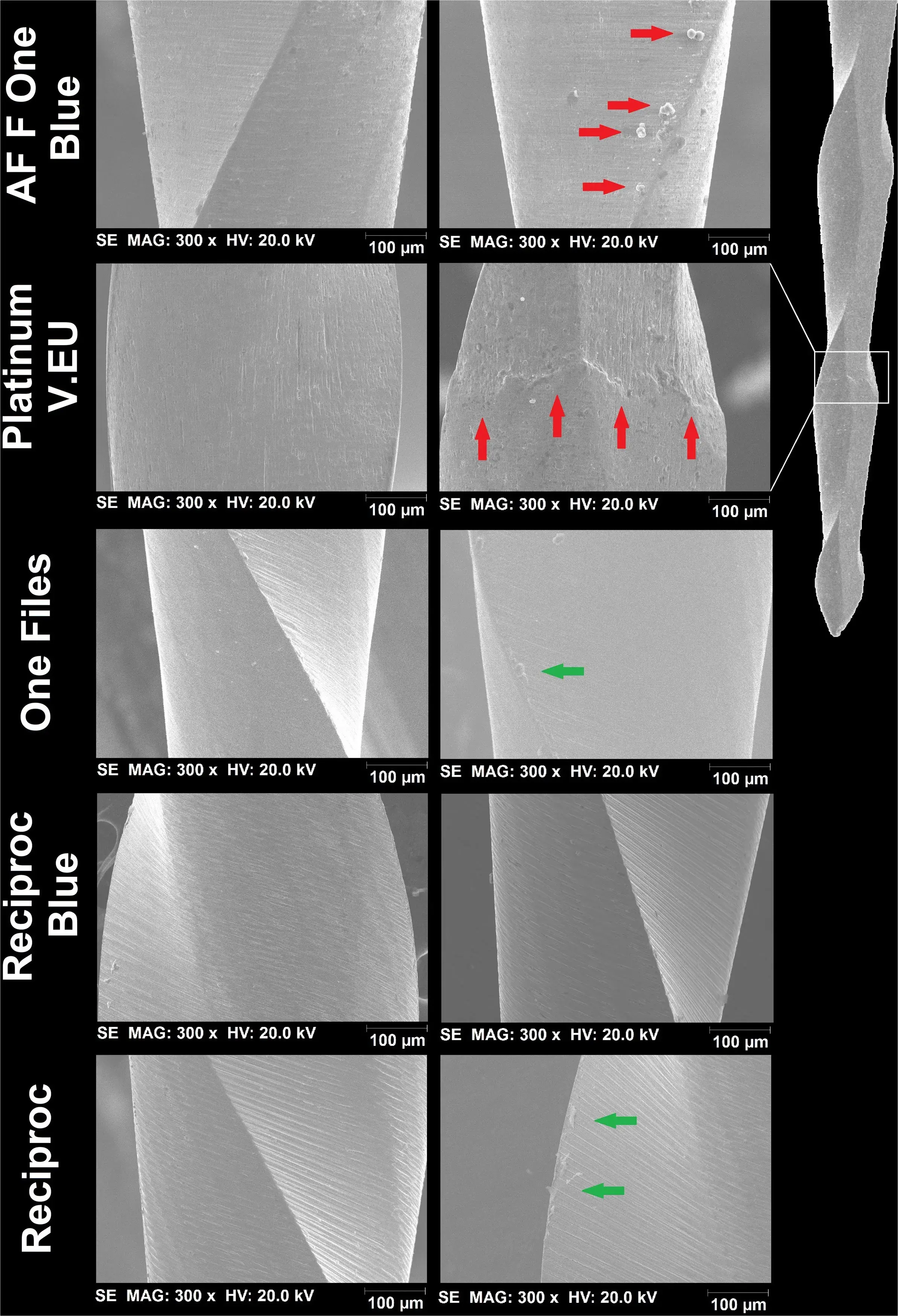

The tested instruments had identical blade counts (n=8) and near-identical helical angles of approximately 24° (rotary instruments) and 151° (reciprocating instruments), without any significant visible deformations (Table 1). In the rotary group, the flat-side positioning was not consistently aligned with the long axis of the active blade, resulting in instruments with different shapes and dimensions within the same blister pack. This lack of standardization was also observed in the tip of AF F One Blue and Platinum V.EU instruments (Figure 2f,g). Furthermore, two AF F One Blue instruments exhibited discontinuity in the flat side (Figure 2f), and several Platinum V.EU instruments had multiple gaps in the bluish colour caused by the heat treatment (Figure 2h). The SEM analysis revealed reciprocating instruments with symmetrical spirals featuring an S-shaped cross-section design. Rotary instruments, on the other hand, displayed expected asymmetry and incomplete S-shaped cross-sections due to the presence of a flat side, and none of the tips were active (Figure 3). Parallel marks consistent with a grinding manufacturing process were observed in the reciprocating instruments (Figure 3). However, in the One Files Blue, these marks appeared to be smoothed out by a polishing process. No significant minor irregularities were observed in any of these instruments (Figure 4). The flat-side instruments displayed a surface finishing that was more irregular, with a few minor surface irregularities. One of the Platinum V.EU instruments showed a more significant surface micro irregularity, possibly indicating some form of surface finishing treatment irregularity/discontinuity (Figure 4).

TABLE 1 Macroscopic design characteristics of tested reciprocating and flat-side instruments.

FIGURE 3 Scanning electron microscopic analyses of tested systems showing representative images of the active blades (×20; on the top), tips (×40; on the middle), and cross-sections at D10 (×80; on the bottom). Rotary instruments (on the left) displayed asymmetric shape with incomplete S-shaped cross-sections due to the presence of a flat side, whilst reciprocating instruments (on the right) have symmetrical spirals and an S-shaped cross-section design. Although none of the tips were active, a high variation in the size and shape of the tips were observed in the flat size instruments.

FIGURE 3 Scanning electron microscopic analyses of tested systems showing representative images of the active blades (×20; on the top), tips (×40; on the middle), and cross-sections at D10 (×80; on the bottom). Rotary instruments (on the left) displayed asymmetric shape with incomplete S-shaped cross-sections due to the presence of a flat side, whilst reciprocating instruments (on the right) have symmetrical spirals and an S-shaped cross-section design. Although none of the tips were active, a high variation in the size and shape of the tips were observed in the flat size instruments.

FIGURE 4 Scanning electron microscopic surface finishing analyses (×300). The left column shows that the two flat-side rotary systems had a more irregular surface, whereas the three reciprocating systems exhibited parallel marks consistent with the manufacturing process. Amongst the reciprocating systems, the One File Blue displayed the smoothest surface. In the right column, it is possible to observe that minor surface irregularities (red arrows) were observed in the rotary instruments, whilst rare irregularities (green arrows) were noted in the reciprocating systems. The presence of a surface finishing treatment irregularity/discontinuity on the active blade of the Platinum V.EU instrument can also be observed.

FIGURE 4 Scanning electron microscopic surface finishing analyses (×300). The left column shows that the two flat-side rotary systems had a more irregular surface, whereas the three reciprocating systems exhibited parallel marks consistent with the manufacturing process. Amongst the reciprocating systems, the One File Blue displayed the smoothest surface. In the right column, it is possible to observe that minor surface irregularities (red arrows) were observed in the rotary instruments, whilst rare irregularities (green arrows) were noted in the reciprocating systems. The presence of a surface finishing treatment irregularity/discontinuity on the active blade of the Platinum V.EU instrument can also be observed.

Metallurgical characteristics

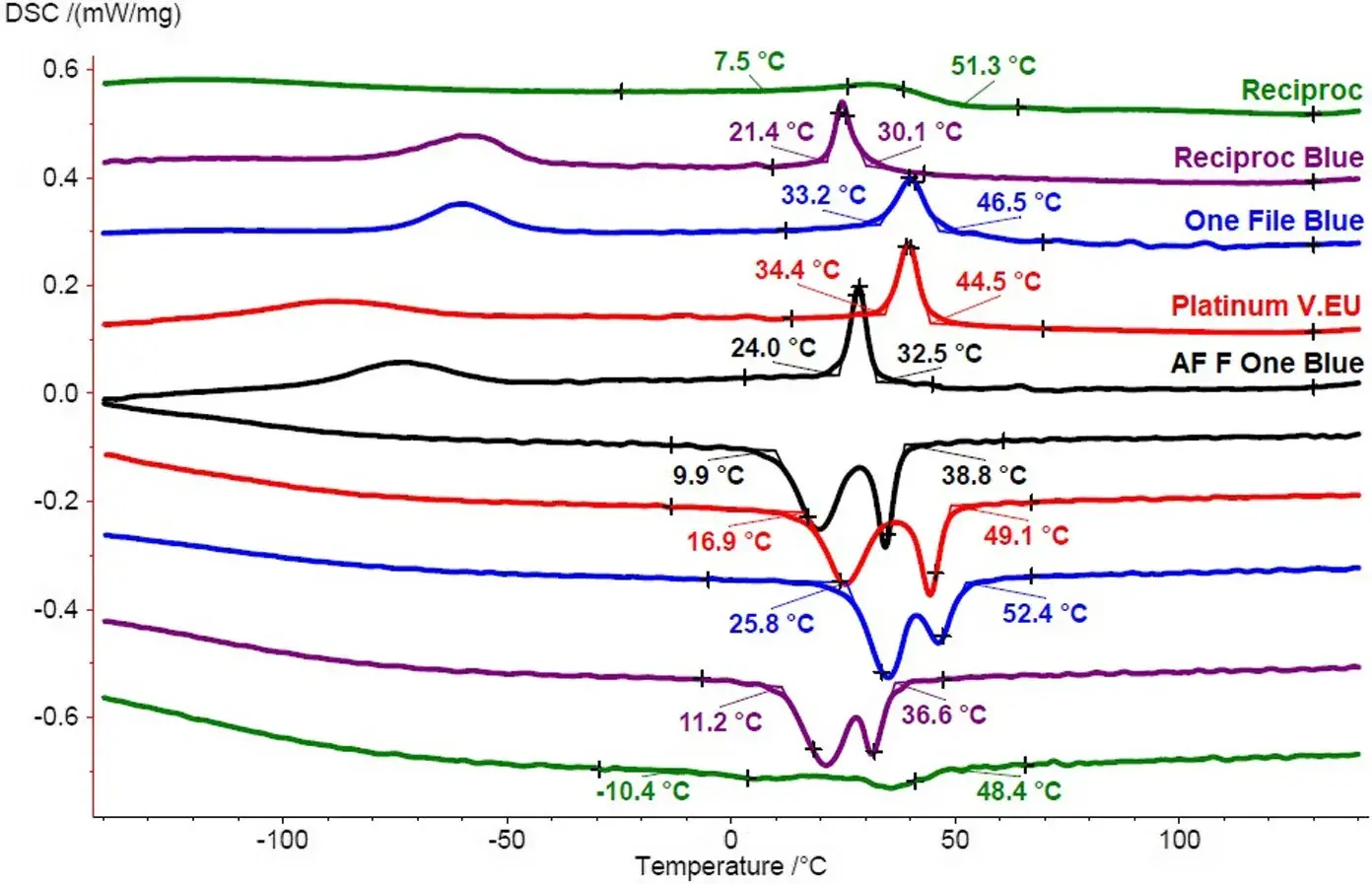

The results of the EDS analysis indicated that all instruments were composed of nearly equiatomic NiTi alloys and did not contain detectable amounts of other metals. The ratio of nickel and titanium elements were 1.021 (AF F One Blue), 1.016 (Platinum V.EU), 1.032 (One Files Blue), 1.028 (Reciproc Blue), and 1.027 (Reciproc). The DSC charts revealed different phase transformation temperatures amongst the tested instruments. Reciproc exhibited the highest R-phase start (Rs) at 51.3°C and the lowest R-phase finish (Rf) at 7.5°C during cooling. Similar phase transformation temperatures were observed for One Files Blue (Rs: 46.5°C; Rf: 33.2°C) and Platinum V.EU (Rs: 44.5°C; Rf: 34.4°C), as well as for Reciproc Blue (Rs: 30.1°C; Rf: 21.4°C) and AF F One Blue (Rs: 32.5°C; Rf: 24.0°C) instruments. On cooling, it appeared that the full phase transformation occurred within the range of room (20°C) and body (36°C) temperatures for the Reciproc Blue and AF F One Blue instruments, but not on heating (Figure 5).

FIGURE 5 Differential scanning calorimetry (DSC) test. DSC charts revealed distinct phase transformation temperatures for all tested instruments. Reciproc exhibited the highest and lowest Rs (51.3°C) and Rf (7.5°C) temperatures during cooling, respectively. All heat-treated instruments were in an R-phase crystallographic arrangement at room temperature, but the Reciproc Blue and AF F One Blue showed full transformation to austenitic within the service temperature range between room (20°C) and body temperature (36°C). As a result, these two instruments are more susceptible to temperature changes than the other instruments tested. Some similarities were observed between the One Files Blue and Platinum V.EU as well as between the Reciproc Blue and AF F One Blue instruments, particularly regarding the Rs and Rf temperatures during cooling. In the graph, cooling temperatures are depicted on top (reading from right to left) and heating temperatures on bottom (reading from left to right).

FIGURE 5 Differential scanning calorimetry (DSC) test. DSC charts revealed distinct phase transformation temperatures for all tested instruments. Reciproc exhibited the highest and lowest Rs (51.3°C) and Rf (7.5°C) temperatures during cooling, respectively. All heat-treated instruments were in an R-phase crystallographic arrangement at room temperature, but the Reciproc Blue and AF F One Blue showed full transformation to austenitic within the service temperature range between room (20°C) and body temperature (36°C). As a result, these two instruments are more susceptible to temperature changes than the other instruments tested. Some similarities were observed between the One Files Blue and Platinum V.EU as well as between the Reciproc Blue and AF F One Blue instruments, particularly regarding the Rs and Rf temperatures during cooling. In the graph, cooling temperatures are depicted on top (reading from right to left) and heating temperatures on bottom (reading from left to right).

Mechanical performance

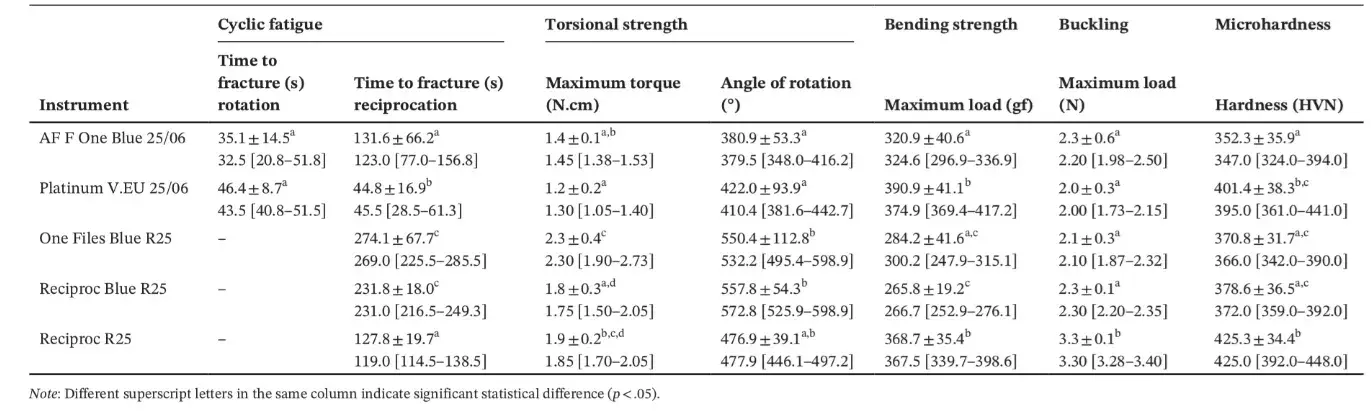

Although the time and number of rotations to fracture of AF F One Blue (35.1 s, 14040) and Platinum V.EU (46.4 s, 16240) instruments showed no significant difference (p=.052 and .307, respectively), there was a statistically significant difference in the clockwise oscillatory asymmetrical motion between them (AF F One Blue: 131.6 s; Platinum V.EU: 44.8 s). Moreover, both instruments showed significantly lower results when compared with One Files Blue (274.1 s) and Reciproc Blue (231.8 s) in counter-clockwise oscillatory asymmetrical motion testing.

The instruments with the lower maximum torques were Platinum V.EU (1.2N.cm) and AF F One Blue (1.4N.cm), whilst Reciproc (1.9N.cm) and One Files Blue (2.3N.cm) exhibited higher maximum torques. Comparable findings were found for the angle of rotation. The bending load test revealed that the Reciproc Blue instrument had the highest flexibility (265.8 gf), whilst the Platinum V.EV had the lowest flexibility (390.9 gf). The maximum buckling load was significantly higher in Reciproc (3.3N) compared with the other instruments (p<.05), which showed equivalent results (p>.05). Reciproc also exhibited the highest surface microhardness (425.3 HVN) compared with the other instruments (p<.05; Table 2). Further details about endodontic treatment are accessible for you to learn in our course "Endodontics: from classic protocols to extreme".

TABLE 2 Mechanical tests results expressed as mean (standard deviation) and median [interquartile range].

DISCUSSION

It is widely recognized that the stresses experienced by an instrument during the root canal treatment differ from those in a controlled laboratory environment. However, testing an instrument until its ultimate strength and final fracture is not feasible in a clinical setting and can only be achieved in a laboratory. Therefore, it has been proposed that a more comprehensive multimethod research approach, incorporating laboratory methodologies and multiple tests, should be employed to address clinical questions. By combining the results of each method, the multimethod approach improves the internal validation and reliability of research. It also allows for a better interpretation of the instruments' performance and a more precise translation of preclinical findings to guide clinical use (Martins et al., 2022).

Despite reports of a low incidence of fractures in rotary and reciprocating instruments in clinics (Bueno et al., 2020; Caballero-Flores et al., 2019; Plotino et al., 2015; Shen et al., 2016), it remains a topic of interest for researchers and clinicians. Even taking into account the possibility of bypassing the fragment, incorporating the fractured instrument into the filling material, or still removing it, this complication is a stressor for the operator who needs to spend further time to address this issue, which commonly requires specialist referral (Gomes et al., 2021). An instrument fracture may be influenced by numerous factors including the preparation protocol, rotational speed, manufacturing technology, canal curvature, and operator skills. In order to overcome these limitations, manufacturers have developed several strategies such as modifications in the type of NiTi alloys, in the activation kinematics, and in the design of instruments (De-Deus et al., 2010; Plotino et al., 2018), as the recently proposed flat-side concept (Gambarini et al., 2019).

To evaluate the mechanical strength of the instruments, two parameters have been repeatedly measured: the time to fracture (or number of rotations to fracture when different rotational speeds are recommended by the manufacturer) during a cyclic fatigue test and the maximum torque sustained during a torsion test. The former indicates the instrument's ability to withstand the stress of rotating inside a curved canal and enduring repeated cycles of compressive and tensile forces, whilst the latter measures its capacity to endure twist stress similar to the pressure of wedging an instrument's tip against the root canal wall (McSpadden, 2007). Additional relevant parameters include the flexibility parameters depicted by the angle of rotation under torsion, which reflects the instrument's ability to withstand deformation before fracture under torsional stress, and the maximum bending load, where lower scores indicate higher flexibility. This characteristic may improve root canal shaping procedures by reducing the chance of deviation from the original canal pathway.

Furthermore, the maximum buckling load can provide an indication of the instrument's ability to withstand light apical pressure without deforming during the root canal preparation procedure (Lopes et al., 2012), whilst microhardness can influence the tensile strength (Gao et al., 2012) and cutting efficacy (Oh et al., 2017) of the instruments. Taken together, these parameters provide a comprehensive understanding of the overall strength of the instruments, which is particularly crucial for single-file systems that are intended to shape the entire root canal, such as reciprocating and the novel flat-side rotary instruments (Fanta Dental, 2023a, 2023b). However, even though it has been claimed that flat-side rotary instruments, like the ones evaluated in this study, can be employed in a sequence of instruments or as a single file (Fanta Dental, 2023b), the current findings demonstrate that the reciprocating instruments outperformed the flat-side instruments in all mechanical tests. The outcomes displayed notable variations, leading to the rejection of the null hypothesis.

In the microscopic analysis, relevant differences were observed in the surface finishing and, notwithstanding Platinum V.EU manufacturer claims to use innovative polishing and nano-coating technology to enhance the cyclic fatigue resistance of their instruments (Bondent, 2023), the surface finishing appears similarly irregular to that of AF F One Blue (Figure 4), which does not have any specific treatment declared by the company. The macroscopic design analysis revealed significant differences between the AF F One Blue and Platinum V.EU instruments with the other tested instruments, such as the presence of a flat side and clockwise spirals. However, inconsistencies were also noted in the manufacturing of the flat side, including discontinuity segments, differing orientations, and gaps in the bluish colour resulting from heat treatment (Figure 2f–h). Although the influence of these factors related to lack of standardization was not tested in the present investigation, it can be speculated that there is a possibility of different behaviours amongst instruments from the same blister pack since they are not uniform, with greater variation at their tips where the differences were more evident (Figure 2f,g). Furthermore, it is possible that the white spots observed in the flat side (Figure 2h) could be attributed to a localized, rapid, and uncontrolled overheating during the machining of the flat side. This could have been caused by incorrect cooling methods, leading to a localized structural alteration in the alloy that could have later been revealed during the heat treatment process. Such alterations may help to explain the multiple inconsistencies observed in the mechanical behaviour of these flat-side instruments, as discussed in the next paragraphs.

The time to fracture of flat-side instruments was lower compared with the reciprocating ones, which can be attributed to the kinematics itself (under the “rotary vs reciprocating” comparison) and the observed irregularities on their surfaces (under the “clockwise vs counter-clockwise oscillatory asymmetric motion with equivalent angles of rotation” comparison). Whilst previous studies have shown that the flat-side design (Gambarini et al., 2019; Ubaed & Bakr, 2022) and the clockwise oscillatory asymmetric motion can increase the time to fracture of rotary instruments (Martins et al., 2020), this effect was not observed in the Platinum V.EU. On the other hand, the AF F One Blue showed an extension in time to fracture, which ultimately resulted in a significantly lower cyclic fatigue strength for the Platinum V.EU. when tested using oscillatory asymmetric motion. Possible explanations for this could be attributed to surface defects noted in the instruments as depicted in Figure 4 or the previously mentioned inconsistencies in the bluish colour resulting from the heat treatment (Figure 2).

The cyclic fatigue test results also demonstrated superior outcomes for the One Files Blue and Reciproc Blue, which may be attributed in part to their crystallographic arrangements at the testing temperature. These instruments exhibit full R-phase, whilst conventional Reciproc displays R-phase plus austenitic. The slightly better performance of the One Files Blue can be attributed to both smoother surface finishing and higher phase transformation temperatures. It is worth noting that all instruments were composed of nickel–titanium alloys, meaning this is not a factor that justifies the observed differences. However, the phase transformation temperatures are significant. A full phase transformation occurred within the room and body service temperature range for both Reciproc Blue and AF F One Blue, making these instruments more susceptible to temperature changes that could result in acquiring more austenitic crystallographic arrangements at higher temperatures and associated changes in behaviour.

In the other mechanical tests, it was observed that both flat-side instruments sustained lower maximum torques and angles of rotation before fracture (AF F One Blue: 1.4 N.cm and 380.9°; Platinum V.EU: 1.2 N.cm and 422.0°). Their design features may be partially responsible for their lower performance, as the inconsistencies in the flat side were more prominent in their tips where the stress on the torsion test setting is applied. Additionally, the instruments' irregular surface finishing, reduced cross-sectional size, and lower tapers (25/.06 compared with 25/.08v from other systems) may also contribute to lower maximum torque values, as these conditions are traditionally associated with lower torsional strength (Kramkowski & Bahcall, 2009). On the other hand, the One Files Blue demonstrated higher maximum torque results (2.3 N.cm), which is in accordance with a previous study (Martins et al., 2021). The Reciproc Blue (572.8°) and One Files Blue (532.2°) showed higher angle of rotation outcomes, which may be explained by their R-phase crystallographic arrangement at the tested temperature (Figure 5).

The results of our investigation on flat-side single-file rotary systems have shed light on some puzzling findings. The maximum bending strength test revealed that the flat-side instruments, which have lower cross-sectional sizes and tapers (25/.06), actually had higher values (less flexibility), contradicting previous evidence suggesting that smaller instruments tend to be more flexible (Hieawy et al., 2015; Ninan & Berzins, 2013). As previously mentioned, a possible explanation for these findings may be linked to the manufacturing process of flat-sided instruments, as the additional machining process could potentially impact their mechanical properties, including flexibility. However, it should be noted that when comparing these results with the cyclic fatigue test, it becomes evident that both flat-side instruments tested herein had lower cyclic fatigue results even when using oscillatory asymmetric motion with equivalent angles of rotation to the reciprocating ones (Table 2). This finding is in line with previous evidence suggesting that lower fatigue results are typically observed in less-flexible instruments (Goo et al., 2017; Hieawy et al., 2015).

In terms of maximum buckling load values, the Reciproc showed the highest results (3.3N), whilst Platinum V.EU (2N), AF F One Blue (2.3N), and Reciproc Blue (2.3N) had comparable outcomes (Table 2). This result may be attributed to the presence of austenitic crystallographic arrangement in Reciproc at the test temperature. In the microhardness test, Reciproc showed higher values (425.0 HVN) than all other heat-treated instruments, which is consistent with a previous research (De-Deus et al., 2017). The only heat-treated instrument that did not show a statistically significant difference from Reciproc was Platinum V.EU (401.4 HVN).

However, this lack of difference may be due to the inconsistencies in the homogeneity of the bluish colour resulting from the heat treatment (Figure 1).

The present study provided valuable insights into the performance of two different flat-side single-file rotary systems in comparison to three single-file reciprocating systems. However, this study had some limitations, such as the lack of comparison with other well-known systems available in the market and with instruments with varying tapers. It is well-recognized that taper may be a confounding factor in the analysis of cyclic fatigue, buckling, and bending resistance tests due to their effect on the mechanical properties of the instrument. Overall, instruments with larger tapers may display lower cyclic fatigue resistance and higher buckling and bending values when compared with their counterparts (McSpadden, 2007). Nonetheless, the multimethod approach employed in this study provides a comprehensive and global understanding of the tested instruments (Martins et al., 2021), making it a significant contribution to the literature. Further research should focus on the unexplored aspects of the flat-side instruments, such as cutting efficiency, debris removal, shaping ability, and biofilm removal to better understand the effect of this new design feature on other parameters.

CONCLUSIONS

Overall, this multimethod investigation revealed that the two tested flat-side single-file rotary instruments underperformed three different single-file reciprocating instruments in terms of cyclic fatigue (with two different clockwise kinematics), maximum torque, angle of rotation, maximum buckling strength, and flexibility. Manufacturing inconsistencies were also observed in some of the flat-side instruments, including discontinuity segments, different orientations, and in the homogeneity of their bluish colour given by the heat treatment.

If you enjoyed reading this article and would like to explore endodontic treatment protocols further, we encourage you to visit Endodontics section on our website.

List of authors:

Jorge N. R. Martins, Emmanuel J. N. L. Silva, Abayomi O. Baruwa, Rui Pereira da Costa, Francisco M. Braz Fernandes, Marco A. Versiani

References

ASTM:E92-17. (2017) Standard test methods for vickers hardness and knoop hardness of metallic materials. pp. 1–27.

ASTM:F2004–17. (2004) Standard test method for transformation temperature of nickel–titanium alloys by thermal analysis. pp. 1–5.

ASTM:F2516-07. (2007) Standard test methods for tension testing of nickel–titanium superelastic materials. pp. 1–3.

Bondent. (2023) For endo products.

Bueno, C.S.P., Oliveira, D.P., Pelegrine, R.A., Fontana, C.E., Rocha, D.G.P., Gutmann, J.L. et al. (2020) Fracture incidence of WaveOne gold files: a prospective clinical study. International Endodontic Journal, 53, 1192–1198.

Caballero-Flores, H., Nabeshima, C.K., Binotto, E. & Machado, M.E.L. (2019) Fracture incidence of instruments from a single-file reciprocating system by students in an endodontic graduate programme: a cross-sectional retrospective study. International Endodontic Journal, 52, 13–18.

De-Deus, G., Moreira, E.J., Lopes, H.P. & Elias, C.N. (2010) Extended cyclic fatigue life of F2 ProTaper instruments used in reciprocating movement. International Endodontic Journal, 43, 1063–1068.

De-Deus, G., Silva, E.J., Vieira, V.T., Belladonna, F.G., Elias, C.N., Plotino, G. et al. (2017) Blue thermomechanical treatment optimizes fatigue resistance and flexibility of the reciproc files. Journal of Endodontics, 43, 462–466.

Di Nardo, D., Miccoli, G., Mazzoni, A., Seracchiani, M., Gambarini, G. & Testarelli, L. (2020) Centering ability of a new nickel-titanium rotary instruments with a peculiar flat-side design: an in vitro study. The Journal of Contemporary Dental Practice, 21, 539–542.

Fanta Dental. (2023a) AF F-ONE (F-ONE details page).

Fanta Dental. (2023b) Professional precise reliable endodontic solutions.

Ferreira, F., Adeodato, C., Barbosa, I., Aboud, L., Scelza, P. & Zaccaro Scelza, M. (2017) Movement kinematics and cyclic fatigue of NiTi rotary instruments: a systematic review. International Endodontic Journal, 50, 143–152.

Gambarini, G., Miccoli, G., Seracchiani, M., Khrenova, T., Donfrancesco, O., D'Angelo, M. et al. (2019) Role of the flat-designed surface in improving the cyclic fatigue resistance of endodontic NiTi rotary instruments. Materials, 12, 2523.

Gao, Y., Gutmann, J.L., Wilkinson, K., Maxwell, R. & Ammon, D. (2012) Evaluation of the impact of raw materials on the fatigue and mechanical properties of ProFile vortex rotary instruments. Journal of Endodontics, 38, 398–401.

Gomes, M.S., Vieira, R.M., Bottcher, D.E., Plotino, G., Celeste, R.K. & Rossi-Fedele, G. (2021) Clinical fracture incidence of rotary and reciprocating NiTi files: a systematic review and meta-regression. Australian Endodontic Journal, 47, 372–385.

Goo, H.J., Kwak, S.W., Ha, J.H., Pedulla, E. & Kim, H.C. (2017) Mechanical properties of various heat-treated nickel-titanium rotary instruments. Journal of Endodontics, 43, 1872–1877.

Hamed, S.A., Shabayek, S. & Hassan, H.Y. (2022) Biofilm elimination from infected root canals using four different single files. BMC Oral Health, 22, 660.

Hamid, H.R., Gluskin, A.H., Peters, O.A. & Peters, C.I. (2018) Rotary versus reciprocation root canal preparation: initial clinical quality assessment in a novice clinician cohort. Journal of Endodontics, 44, 1257–1262.

Hieawy, A., Haapasalo, M., Zhou, H., Wang, Z.J. & Shen, Y. (2015) Phase transformation behavior and resistance to bending and cyclic fatigue of ProTaper gold and ProTaper universal instruments. Journal of Endodontics, 41, 1134–1138.

Hülsmann, M., Peters, O.A. & Dummer, P.M. (2005) Mechanical preparation of root canals: shaping goals, techniques and means. Endodontic Topics, 10, 30–76.

ISO3630-3631. (2008) Dentistry – Root canal instruments – Part 1: General requirements and test methods.

Kramkowski, T.R. & Bahcall, J. (2009) An in vitro comparison of torsional stress and cyclic fatigue resistance of ProFile GT and ProFile GT series X rotary nickel-titanium files. Journal of Endodontics, 35, 404–407.

Lee, W., Hwang, Y.J., You, S.Y. & Kim, H.C. (2013) Effect of reciprocation usage of nickel–titanium rotary files on the cyclic fatigue resistance. Australian Endodontic Journal, 39, 146–150.

Lopes, H.P., Elias, C.N., Mangelli, M., Lopes, W.S., Amaral, G., Souza, L.C. et al. (2012) Buckling resistance of pathfinding endodontic instruments. Journal of Endodontics, 38, 402–404.

Madarati, A.A., Sammani, A.M.N., Alnazzawi, A.A. & Alrahlah, A. (2023) Efficiency of the new reciprocating and rotary systems with or without ultrasonics in removing root-canals filling with calcium silicate-based sealer (MTA). BMC Oral Health, 23, 5.

Martins, J.N.R., Martins, R.F., Braz Fernandes, F.M. & Silva, E. (2022) What meaningful information are the instruments mechanical testing giving us? A comprehensive review. Journal of Endodontics, 48, 985–1004.

Martins, J.N.R., Nogueira Leal Silva, E.J., Marques, D., Ginjeira, A., Braz Fernandes, F.M., De Deus, G. et al. (2020) Influence of kinematics on the cyclic fatigue resistance of replicalike and original brand rotary instruments. Journal of Endodontics, 46, 1136–1143.

Martins, J.N.R., Silva, E., Marques, D., Belladonna, F., Simoes-Carvalho, M., Vieira, V.T.L. et al. (2021) Design, metallurgical features, mechanical performance and canal preparation of six reciprocating instruments. International Endodontic Journal, 54, 1623–1637.

McSpadden, J.T. (2007) Mastering the concepts. In: McSpadden, J.T. (Ed.) Mastering endodontics instrumentation. Chattanooga, USA: Cloudland Institute, pp. 7–36.

Mogahed, N., Nagy, M.M. & Aziz, T. (2021) Cleaning ability and apically extruded debris of three single file rotary nickel titanium systems (an in vitro study). Ain Shams Dental Journal, 24, 1–10.

Nagendrababu, V., Murray, P.E., Ordinola-Zapata, R., Peters, O.A., Rôças, I.N., Siqueira, J.F., Jr. et al. (2021) PRILE 2021 guidelines for reporting laboratory studies in endodontology: a consensus-based development. International Endodontic Journal, 54, 1482–1490.

Ninan, E. & Berzins, D.W. (2013) Torsion and bending properties of shape memory and superelastic nickel–titanium rotary instruments. Journal of Endodontics, 39, 101–104.

Oh, S.H., Ha, J.H., Kwak, S.W., Ahn, S.W., Lee, W. & Kim, H.C. (2017) The effects of torsional preloading on the torsional resistance of nickel–titanium instruments. Journal of Endodontics, 43, 157–162.

Peters, O.A., Arias, A. & Choi, A. (2020) Mechanical properties of a novel nickel-titanium root canal instrument: stationary and dynamic tests. Journal of Endodontics, 2020, 994–1001.

Plotino, G., Grande, N.M. & Porciani, P.F. (2015) Deformation and fracture incidence of Reciproc instruments: a clinical evaluation. International Endodontic Journal, 48, 199–205.

Plotino, G., Grande, N.M., Testarelli, L., Gambarini, G., Castagnola, R., Rossetti, A. et al. (2018) Cyclic fatigue of Reciproc and Reciproc blue nickel–titanium reciprocating files at different environmental temperatures. Journal of Endodontics, 44, 1549–1552.

Puentes, C.G., Jaime, A. & Versiani, M. (2017) Evolução dos instrumentos endodônticos: das limas manuais ao movimento reciprocante. In: De Deus, G., Silva, E., Souza, E., Versiani, M. & Zuolo, M. (Eds.) O movimento reciprocante na endodontia, 1st edition. São Paulo: Quintessence Publishing, pp. 49–75.

Robinson, J.P., Lumley, P.J., Cooper, P.R., Grover, L.M. & Walmsley, A.D. (2013) Reciprocating root canal technique induces greater debris accumulation than a continuous rotary technique as assessed by 3-dimensional micro-computed tomography. Journal of Endodontics, 39, 1067–1070.

Shen, Y., Coil, J.M., Mo, A.J., Wang, Z., Hieawy, A., Yang, Y. et al. (2016) WaveOne rotary instruments after clinical use. Journal of Endodontics, 42, 186–189.

Ubaed, H.R. & Bakr, D.K. (2022) Cyclic fatigue resistance of nickel–titanium rotary instruments after simulated clinical use. Applied Bionics and Biomechanics, 2022, 1716008–1716007.

Yared, G. (2008) Canal preparation using only one Ni–Ti rotary instrument: preliminary observations. International Endodontic Journal, 41, 339–344.