Mechanical Tests, Metallurgical Characterization, and Shaping Ability of Nickel-Titanium Rotary Instruments: A Multimethod Research

Abstract

Introduction: This study aimed to compare the mechanical and metallurgical properties and shaping ability of different rotary systems using a multimethod approach.

Methods: New NeoNiti A1 (Neolix SAS, Châtres-La-Forêt, France), HyFlex EDM One File (Coltène/ Whaledent, Altstätten, Switzerland), ProTaper Gold F2 (Dentsply Maillefer, Ballaigues, Switzerland), and ProTaper Universal F2 (Dentsply Maillefer) rotary instruments were tested regarding cyclic fatigue, torsional resistance, design, and morphologic characteristics using scanning electron microscopy, metal alloy characterization using differential scanning calorimetry, and energy-dispersive X-ray spectroscopy. Additionally, their shaping ability on the preparation of 48 canals of maxillary molars was evaluated using micro–computed tomographic technology. Mechanical and metallurgical analyses were compared using analysis of variance post hoc Tukey tests, whereas the independent Student t test was used to compare the shaping ability of the ProTaper systems or the thermomechanically treated instruments. The significance level was set at 5%.

Results: The highest cyclic fatigue was observed with the NeoNiti and HyFlex EDM instruments (P > .05), whereas HyFlex EDM had the highest angular rotation to fracture (P < .05). Scanning electron microscopic/energy-dispersive X-ray spectroscopic analyses confirmed similarities in the instruments’ design and an almost equiatomic composition of the systems. Differential scanning calorimetry showed that ProTaper Gold had higher transformation temperatures than ProTaper Universal, whereas a similar transformation was observed between NeoNiti and HyFlex. Micro–computed tomographic analysis revealed that, despite the fact that none of the systems was able to prepare all root canal walls, no statistical differences were observed in either ProTaper systems (P > .05) or the thermomechanically treated instruments (P > .05).

Conclusions: Apart from differences in the mechanical tests and metallurgical characterization, systems with comparable instrument dimensions and preparation protocols showed a similar percentage of untouched surface areas in the root canal preparation of maxillary molars. (J Endod 2020;46:1485–1494.)

The introduction of nickel-titanium (NiTi) rotary instruments in endodontic practice has brought many advantages compared with stainless-steel instruments, including better cutting efficiency, faster preparation time, and improved canal centering ability. However, their use presents the risk of fracture by torsional stress or cyclic fatigue, which might negatively contribute to the outcome of root canal treatment. Hence, several methods have been proposed to enhance the mechanical properties of NiTi instruments, including changes not only in their cross-sectional design and kinematics, but also the thermal treatment of the NiTi alloy. During the thermal treatment, the NiTi instrument undergoes a complex heating-cooling treatment that allows the control of the transition temperatures, creating a shape memory alloy.

ProTaper Gold (Dentsply Maillefer, Ballaigues, Switzerland) is a NiTi rotary system that presents the same geometric design of ProTaper Universal (Dentsply Maillefer) but, because of its proprietary alloy treatment, is more flexible and more resistant to fatigue. On the other hand, the high toughness and the unique superelastic behavior of the NiTi alloy have caused its machining characteristics to be quite complicated. Therefore, a special manufacturing technology known as an electric discharge machine (EDM) was developed. It consists of sparks produced by high-energy and high-frequency electric discharges between the metal workpiece and an electrode that leads to melting and evaporation of the workpiece material locally, resulting in the finished product of the desired geometry, which can be used to produce NiTi instruments with sharp cutting edges, built-in abrasive properties, variable changing profiles, and high flexibility. HyFlex EDM (Coltène/Whaledent, Altstätten, Switzerland) and NeoNiti (Neolix SAS, Châtres-La-Forêt, France) instruments are examples of NiTi rotary systems produced with this type of technology. In previous studies, these instruments showed higher cyclic fatigue resistance compared with others produced with conventional or other martensitic NiTi alloys.

The mechanical properties of NiTi rotary instruments have been often evaluated in scientific studies to rank different systems regarding their safety or performance. Despite the fact that the parameters tested in these studies can be useful to understand their flexibility and torsional resistance, the clinical relevance of these mechanical tests isolated has been considered low because clinical usage can be affected by several other factors. Consequently, a multimethod approach combining the results of different mechanical tests and the shaping ability of different NiTi systems would be of benefit for a better interpretation of their performance and, consequently, a more precise translation of preclinical findings to guide the clinical use.

Therefore, the present study aimed to compare NeoNiti (Neolix SAS, Châtres-La-Forêt, France), HyFlex EDM (Coltène/Whaledent, Altstätten, Switzerland), ProTaper Gold, and ProTaper Universal rotary systems regarding their cyclic fatigue and torsional resistance, manufacturing design, metallurgical characteristics, and shaping ability. The null hypotheses to be tested were that there were no differences among the tested systems concerning their mechanical performance, metallurgical characterization, and shaping ability.

Materials and Methods

Mechanical Tests

New NeoNiti A1 (size 25, 0.08 taper over the first 4 mm; Neolix SAS), HyFlex EDM One File (size 25, 0.08 taper over the first 4 mm; Coltène/Whaledent), ProTaper Gold F2 (size 25, 0.08 taper over the first 3 mm; Dentsply Maillefer), and ProTaper Universal F2 (size 25, 0.08 taper over the first 3 mm; Dentsply Maillefer) rotary instruments were tested regarding cyclic fatigue and torsional resistance. Before testing, instruments were examined for deformities under a stereomicroscope at X20 magnification (Stemi 2000-C; Carl Zeiss, Jena, Germany), and no instrument was discarded. Powered on data from previous studies, a power calculation was performed (G*Power 3.1; Heinrich-Heine-Universität Düsseldorf, Düsseldorf, Germany) and indicated that the sample size for each group should be a minimum of 10 instruments for both tests.

Cyclic Fatigue

The cyclic fatigue test was performed using a custom-made device that allowed a reproducible simulation of an instrument confined in a curved canal. The artificial canal was created on a nontapered 19-mm stainless steel tube. This tube had 3 segments. The first was straight and had 7 mm in length. The second was curved (9-mm length, 6-mm radius, and 86° curvature) with the position of maximum stress in the middle of its length. The last was a 3-mm straight segment. The steel walls were 1.3 mm thick with an inner diameter of 1.4 mm. The block containing the artificial canal was connected to a mainframe to which a mobile support for the handpiece was attached to allow a precise and reproducible placement of the instruments to the same depth inside the simulated canal. The instruments of each tested system (n = 10 per group) were activated with a 6:1 reduction handpiece (Sirona Dental Systems GmbH, Bensheim, Germany) powered by a torque- controlled motor (VDW Silver; VDW GmbH, Munich, Germany) with a continuous clockwise rotation at 250 rpm and 1.5-N.cm torque. All instruments were tested continuously using a lubricant at room temperature until rupture occurred. The time to fracture was recorded in seconds with a digital chronometer and stopped when the file fracture was detected visually and/or audibly. The number of cycles to failure (NCF) of each file was calculated at 250 rpm using the following formula: NCF 5 revolution per minute (rpm) X time (seconds)/60. The size of the fractured segments was recorded only for the experimental control.

Torsional Resistance

The torsional load was applied until fracture to estimate the mean ultimate torsional strength and the angle of rotation of the tested instruments (n = 10 per group) using a custom-made device produced according to ISO 3630-1. Each instrument was clamped at a distance of 3 mm from the tip using a chuck connected to a torque-sensing load cell. Then, the shaft of the instrument was fastened into an opposing chuck able to be rotated with a stepper motor. All instruments were rotated in the clockwise direction at a speed of 2 rpm until fracture occurred. The torsional load (N.cm) and angular rotation (°) were recorded continuously using a torsiometer (ODEME, Luzerna, SC, Brazil), and the ultimate torsional strength and angle of rotation at failure were provided by specifically designed computed software (ODEME Analysis TT, ODEME).

Metallurgical Characterization

Scanning Electron Microscopy

A scanning electron microscope (JSM 5800; JEOL, Tokyo, Japan) was used to evaluate new instruments from each tested system regarding its tip, cutting edge, flute, and intermediate and cross-sectional design at X100 magnification., while the topographic features of the fracture surfaces of all instruments were evaluated after cyclic and torsional tests at X250 and X1000 magnifications.

Energy-dispersive Spectroscopy Three brand new instruments from each tested system were evaluated regarding the energy- dispersive spectroscopic (EDS) analysis using a scanning electron microscope (Hitachi S- 2400; Hitachi High-Tech Corporation, Tokyo, Japan) equipped with an energy-dispersive

X-ray spectrometer with a light elements detector (Bruker Quantax; Bruker Corporation, Billerica, MA), connected to a Dell Precision T3500 (Dell Inc, Round Rock, TX) desktop computer. The operative parameter settings included an acceleration voltage of 20 kW and a filament current of 3.1 A at a 25-mm work distance. Sampling consisted of a 400 X 400 mm area of the instruments, and acquisitions were made with a 60-second life time with an approximately 30% dead time. Data were assessed using Sigma Scan software (Systat Software Inc, San Jose, CA), and the proportions of nickel and titanium were obtained by a typical spectrum produced by the software.

Differential Scanning Calorimetry Differential scanning calorimetric (DSC) analysis followed the recommendations of the American Society for Testing and Materials. A 5-mm fragment weighing 15–20 mg from the coronal active portion of each tested instrument was submitted to a chemical etching bath with hydrofluoric acid followed by nitric acid and finishing with distilled water for approximately 2 minutes. The samples were weighed (M-Power Microbalance; Sartorius, Göttingen, Germany) and placed in an aluminum pan. An empty aluminum pan served as the control. The test was conducted on a differential scanning calorimeter (DSC 204 F1 Phoenix; Netzsch-Gerätebau GmbH, Selb, Germany) connected to an Asus desktop computer (Asus, Taipei, Taiwan) from where the Netzsch Proteus Thermal Analysis software (Netzsch-Ger€atebau GmbH) was accessed and DSC charts extracted. These charts allowed the visual analysis of the austenite start, austenite finish, martensitic start, and martensitic finish temperatures.

Each thermic cycle test duration was approximately 1 hour and 40 minutes. It started with a room temperature stabilization for 5 minutes followed by heating up to 150°C with a pace of 10°C per minute. At the maximum temperature level, a stabilization plateau for 2 minutes was performed and then started a cooling cycle, which decreased until -150°C at a pace of 10°C per minute followed by a 5-minute stabilization plateau. A new heating phase was induced until 150°C at a pace of 10°C once more followed again by a 2-minute stabilization plateau. At the end, the temperature decreased to room temperature, and a final 2-minute stabilization plateau was performed. Two tests on 2 different instruments from the same system were conducted. The second test intended to confirm the result of the first one. A third test was performed if the transformation phases of the 2 previous tests were nonconcordant in more than 10°C.

Shaping Ability

Specimen Selection and Groups

An a priori independent samples test was selected from the t test family (G*Power 3.1 for Macintosh; Heinrich-Heine-Universität-Du€sseldorf). The effect size (0.91) was determined using data from De-Deus et al in which the shaping ability was assessed. Other parameters were used as follows: an alpha- type error of 0.05 and a power beta of 0.95. Sixteen root canals (n = 8 per group) were indicated as the sample size needed to observe significant differences between a pair of groups. Twelve root canals per group were used to prevent possible losses during the experimental procedures.

Sixteen three-rooted human maxillary first molars with fully formed apices and a single root canal in each root (48 root canals) were selected from a pool of extracted teeth and imaged at a pixel size of 19 mm using a micro–computed tomographic (micro-CT) device (SkyScan 1174v.2; Bruker microCT, Kontich, Belgium). The scanner parameters were set at 50 kV, 800 mA, 180° rotation around the vertical axis, and a rotation step of 0.6° using a 1-mm-thick aluminum filter. The projection images were reconstructed into cross-sectional slices using NRecon v.1.6.9 software (Bruker-microCT) with a beam hardening correction of 15%, smoothing of 3, ring artifact correction of 3, and an attenuation coefficient ranging from 0.01–0.15.

Preoperative 3-dimensional models of the root and root canals were rendered (CTVol v.2.2.1, Bruker-microCT) and qualitatively evaluated regarding root canal configuration. Then, 3D parameters of the root canals (length, volume, surface area, and structure model index) were calculated from the cementoenamel junction level to the apex using CTAn v.1.14.4 software (Bruker-microCT). In order to enhance the internal validity of the experiment, the selected specimens were matched to create 2 sets of 8 teeth (n = 24 canals) based on the morphologic aspects of the root canals. Then, each set of teeth was assigned to either ProTaper (ProTaper Universal and ProTaper Gold) or thermomechanically treated (NeoNiti and HyFlex EDM) groups and randomly subdivided into 2 experimental subgroups (n = 12 canals) according to the preparation systems. The analyzed 3D morphometric parameters of the root canals in each set of teeth were normality distributed (Shapiro-Wilk test) and homoscedastic (Levene test), and the degree of homogeneity (baseline) of the subgroups was statistically confirmed (P > .05, independent sample t test).

Root Canal Preparation

Conventional access cavities were prepared, canals were accessed, and patency was confirmed with a size 10 K-file (Dentsply Maillefer). When the tip of the instrument was visible through the main foramen, 0.5 mm was subtracted to determine the working length (WL). Then, a glide path was achieved to the WL with a size 15 K-file (Dentsply Maillefer). All instruments were taken to the WL in a continuous clockwise rotation generated by a 6:1 angle handpiece (Sirona Dental Systems GmbH) powered by an electric motor (VDW Silver Motor, VDW GmbH) according to the manufacturers’ directions. During preparation procedures, after 3 gentle in-and-out motion strokes in an apical direction, the instrument was removed from the canal and cleaned. This was repeated until the WL was reached, and then the instrument was discarded. In the NeoNiti group (n = 12), canals were enlarged to the WL using instrument sizes 20/.06 and 25/.08v (A1) in the buccal canals, whereas the palatal canal was enlarged up to a size 40/.04. In the HyFlex EDM group (n = 12), buccal canals were prepared with instrument sizes 20/.05 and 25/.08v (One File) up to the WL, whereas the palatal canal was enlarged up to a size 40/.04. The instrument sequence in the ProTaper Gold (n = 12) and ProTaper Universal (n = 12) groups was S1, S2, F1, and F2 (25/.08v) to the WL in the buccal canals, whereas the palatal canal was additionally enlarged with the F4 (40/.06v) instrument. After each step, the canals were irrigated with 5 mL 2.5% sodium hypochlorite using a disposable syringe fitted with a 30-G NaviTip needle (Ultradent, South Jordan, UT) placed 1 mm from the WL. A final rinse with 5 mL 17% EDTA was followed by a 5-mL rinse with distilled water. Then, canals were dried with paper points (Dentsply Maillefer), imaged with a micro-CT system, and reconstructed using the same previously mentioned parameters. One set of instruments were used to prepare 3 canals, and all preparation procedures were performed by a trained operator.

Micro-CT Evaluation

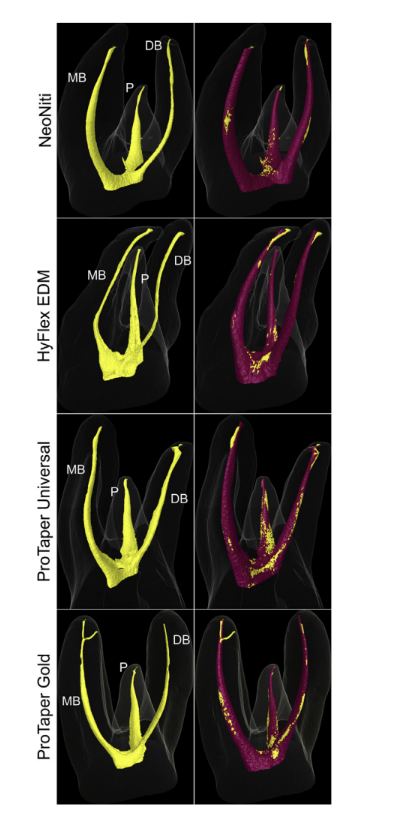

Pre- and postoperative models of the canals were rendered (CTAn v.1.14.4) and coregistered with their respective preoperative data sets using the rigid registration module of the 3D Slicer 4.3.1 software (available from http://www.slicer.org). A qualitative comparison between groups was performed with CTVol v.2.2.1 software using color-coded models of the matched root canals (yellow and purple colors indicate pre- and postoperative canal surfaces, respectively). Postoperative 3D parameters were also evaluated (CTAn v.1.14.4). Spatially registered surface models of the roots were then compared regarding the unprepared area of the root canal walls, which was calculated by using the distances between the surface of the root canals before and after preparation determined at every surface point. Then, the percentage of the remaining unprepared surface area was determined using the formula (Au/Ab)*100, where Au represents the unprepared canal area and Ab the root canal area before preparation. Specific comparisons between similar preparation systems in terms of dimensions and the sequence of the instruments (NeoNiti X HyFlex EDM and ProTaper Gold X ProTaper Universal) was performed. An examiner blinded to the preparation protocols performed all of the analyses.

Statistical Analysis

The Shapiro-Wilk and Levene tests were used to evaluate the assumption of normality and the equality of variance of the data sets.

Considering that the results were normally distributed (P > .05), they were presented as the mean, standard deviation, and interval range. For the mechanical and metallurgical characterization analyses, results were statistically compared among groups using analysis of variance and post hoc Tukey tests. For shaping ability, NeoNiti X HyFlex EDM and ProTaper Gold X ProTaper Universal were compared using the independent Student t test. The significance level was set at 5% (SPSS v18.0 for Windows; SPSS Inc., Chicago, IL).

Results

Mechanical Tests

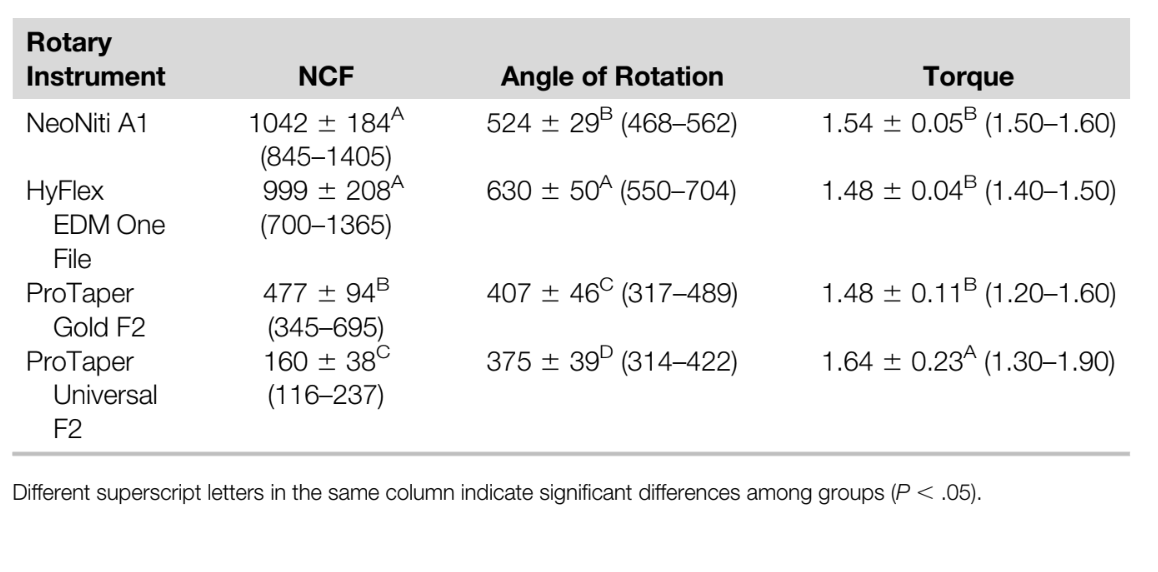

The results of the NCF, angular rotation to fracture (°), and the torque required to fracture (N.cm) are presented in Table 1. The highest NCF values were observed with NeoNiti A1 (1042 ± 184) and HyFlex EDM One File (999 ± 208) instruments (P > .05), whereas ProTaper Universal F2 showed the lowest NCF values (160 ± 38) (P < .05). HyFlex EDM One File had a higher angular rotation to fracture compared with the other instruments (P < .05), whereas ProTaper Universal F2 showed the lowest angular rotation to fracture (P < .05). ProTaper Universal F2 also required the highest torque values to fracture amongst the tested instruments (P < .05).

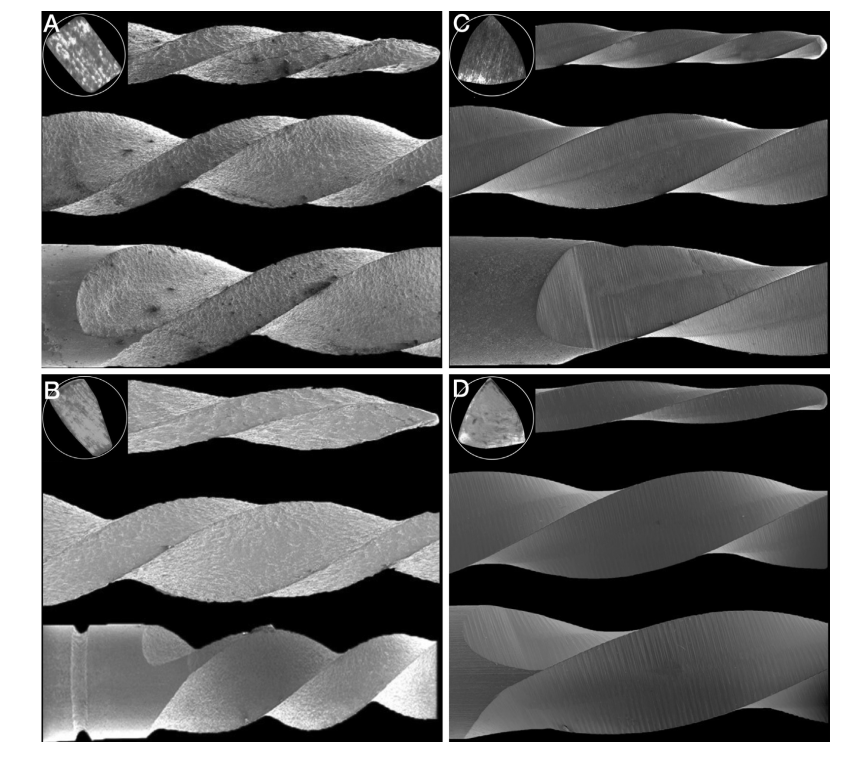

Metallurgical Characterization Overall, the surface quality appearance of NeoNiti A1 and HyFlex EDM One File was similar. These instruments showed an isotropic surface characterized by a regular distributor crater which is often observed in materials that have undergone the electric discharge machining process. Only a small number of defects such as barbs in the cutting edge could be observed. HyFlex EDM One File showed a trapezoidal cross section, whereas a rectangular cross section was observed in the NeoNiti A1 instrument. Moreover, the NeoNiti instrument showed a slight rounding tip- transition angle, whereas HyFlex EDM had a more active tip feature (Fig. 1A and B).

Regarding the ProTaper systems, a smooth surface was observed demonstrating an overall good finishing quality, with only a small number of defects/porosities detected in the cutting edges and flutes. The thermal treatment of the ProTaper Gold instruments resulted in a smooth and improved finishing surface. Both ProTaper Universal and ProTaper Gold instruments had a convex triangular cross section and a slight rounding- tip transition angle (Fig. 1C and D).

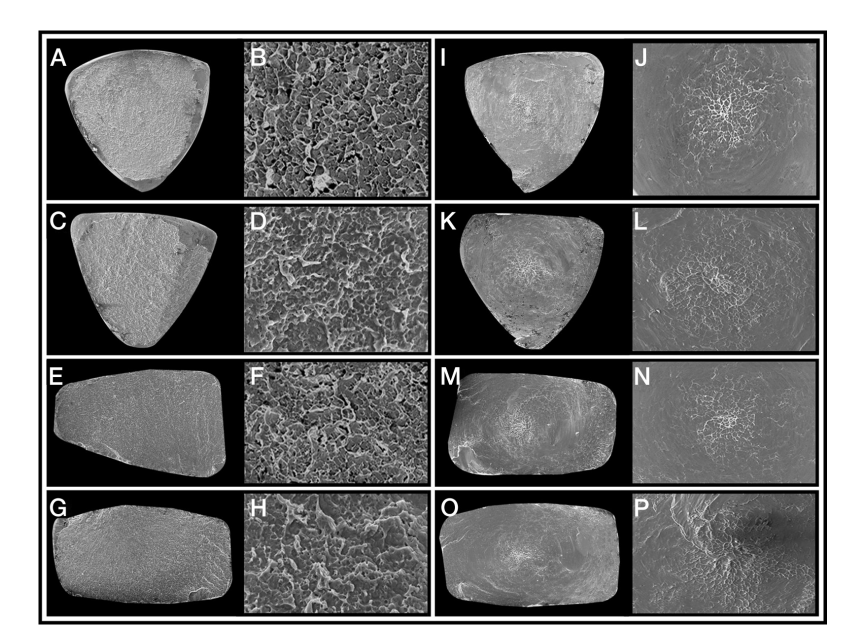

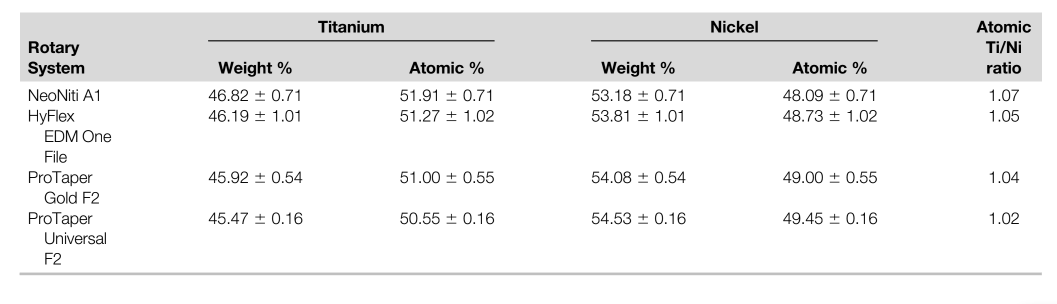

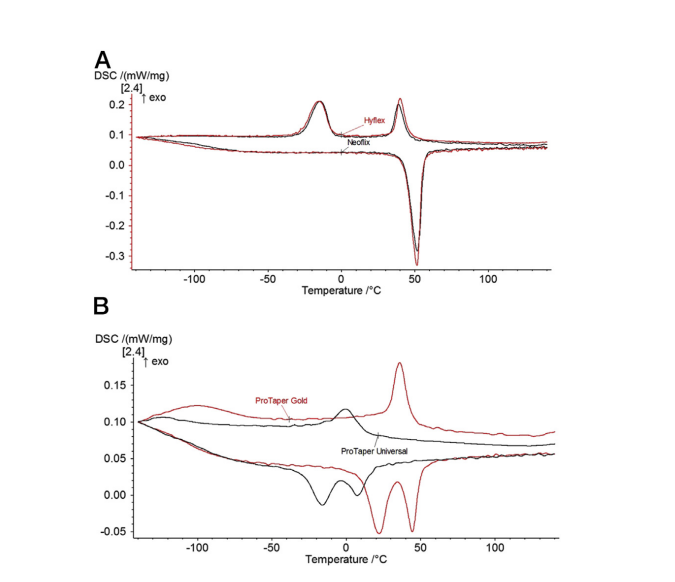

Scanning electron microscopy of the fracture surfaces of the instruments showed similar and typical features of cyclic fatigue and torsional failure (Fig. 2). For both tests, the fracture surfaces presented characteristics of the ductile type. However, differences in the fracture mechanisms led to dissimilar surface aspects. Although microvoids were distributed over the entire surface area of the instruments submitted to the cyclic fatigue test (Fig. 2A–H), the fracture surfaces displayed 2 zones after the torsional strength experiment: the first one with microvoids located at the center of the instruments (core) and the second represented by a plastic deformation around the microvoids (Fig. 2I–P) because of the shear stresses originated during the twisting. EDS and DSC analyses revealed a similar equiatomic composition of titanium and nickel elements for all tested systems (Table 2) and similar transformation characteristics of the NeoNiti and HyFlex EDM instruments (Fig. 3A), respectively. On the other hand, ProTaper Gold showed higher transformation temperatures and much sharper and well- defined transformation peaks than ProTaper Universal in the DSC test (Fig. 3B).

Taper Gold than ProTaper Universal.

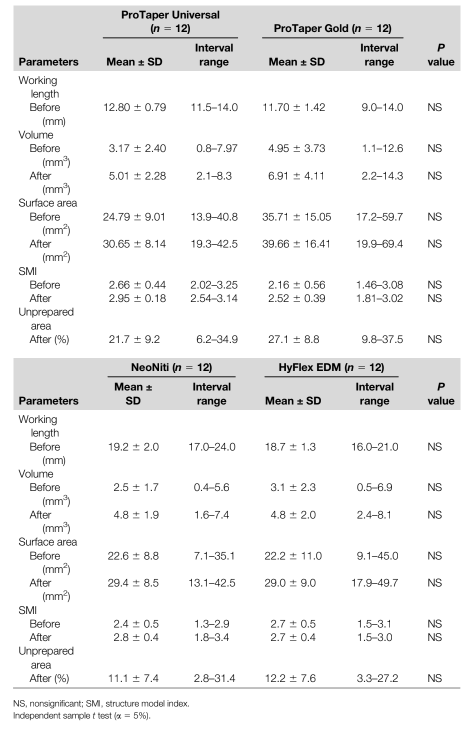

Shaping Ability

No statistical differences were observed regarding all tested 3D parameters, before or after preparation, when comparing the shaping ability of either ProTaper (ProTaper Universal and ProTaper Gold) or thermomechanically treated (NeoNiti and HyFlex EDM) systems (Table 3) (P > .05). None of the preparation protocols was able to prepare all of the root canal walls (Fig. 4) with a percentage of unprepared surface area ranging from 11.1% (NeoNiti) to 27.1% (ProTaper Gold) (Table 3).

Discussion

Recently, the scientific value of studies on the fatigue resistance of rotary and reciprocating instruments was questioned. It was highlighted that results from these studies were useless for readers looking for a specific NiTi preparation system considering that the large variability of the tested protocols would make comparison difficult and problematic among studies. It was also pointed out that this type of research does not resemble the reality because pure rotation inside an artificial canal without any torque on the instrument, such as in cyclic fatigue tests, was unlikely to happen in a clinical scenario. Although these statements are true, it is important to emphasize that cyclic fatigue and torsional resistance tests allow the variables to be isolated and tested individually, increasing the internal validity and reproducibility of the study, which is in agreement with basic concepts of the scientific method. However, despite these tests allow an appropriate assessment of the resistance behavior of NiTi instruments, it is also true that solely evaluating these outcomes might provide only partial information to the readers about the tested preparation systems. Therefore, the present study used a multimethod research approach, including purely mechanical tests with the metallurgical characterization of the tested systems, associated with the evaluation of their shaping ability in extracted teeth using nondestructive micro-CT technology, for a better and overall comprehension of their performances.

In this study, the cyclic fatigue resistance of HyFlex EDM One File and NeoNiti A1 was similar but higher than ProTaper F2 instruments (Table 1). The innovative thermomechanically treated NiTi alloy and the EDM treatment of HyFlex EDM and NeoNiti associated with the largest dimensions of the ProTaper F2 instrument might explain this finding. Similar results were also observed by Kaval et al, who reported superior cyclic fatigue resistance of HyFlex EDM compared with ProTaper Universal and ProTaper Gold instruments. The similar fatigue resistance results between HyFlex EDM and NeoNiti might be explained by the fact that, despite small differences in their cross-sectional design, these instruments present not only comparable dimensions (tip and taper) and quality of manufacturing (Fig. 1) but also similar metallurgical properties as observed in both EDS and DSC assays (Table 2 and Fig. 3). In contrast, ProTaper Gold showed a remarkable NCF compared with ProTaper Universal. For these instruments, the influence of the design (Fig. 1) or Ni/Ti ratio composition (Table 2) on the results can be excluded as variable factors considering that they only differ regarding the thermomechanical manufacturing process. It has been demonstrated that martensitic NiTi alloys, such as in ProTaper Gold instruments, present high malleability and, consequently, outperformed conventional austenitic NiTi alloys in resistance tests. Besides, ProTaper Universal was fully austenitic at room temperature and thus present superelastic behavior at and above room temperature as confirmed by DSC analysis (Fig. 3). ProTaper Gold showed higher transformation temperatures because of the presence of R-phase and much sharper and well-defined transformation peaks than ProTaper Universal (Fig. 3), indicating that ProTaper Gold instruments were subject to a higher temperature and/or a longer duration final heat treatment (aging).

The results of the torsional resistance test demonstrated that the maximum torsional strength of ProTaper Universal (1.64 ± 0.23 N.cm) was significantly higher than all of the other tested instruments (Table 1). This finding suggests that in a clinical situation in which the tip of an instrument binds to the canal, the ProTaper Universal instrument will require a higher strength to fracture. However, this may be jeopardized by its lowest angular rotation to fracture (375.1° ± 39.2°) explained by its fully austenitic structure at room temperature (Fig. 3). On the other hand, the higher angular rotation to fracture of HyFlex EDM (630.2 ± 50.5°) and NeoNiti (524.4° ± 29.2°) compared with the ProTaper instruments (Table 1) may be helpful in practice as an indicator for plastic deformation and imminent fracture.

Additionally, differences in the angular rotation to fracture between the HyFlex EDM and NeoNiti instruments could only be explained by the slight differences in their cross-sectional designs and surface finish quality (Fig. 1) because both instruments showed transformation characteristics that were virtually equivalent (Fig. 3). Therefore, considering the differences observed in the mechanical tests and metallurgical characterization, the first and second null hypotheses tested were rejected.

Despite the fact that mechanical tests and metallurgical characterization methods have been used systematically in several studies providing important and comparable information regarding the physical properties of different NiTi instruments, it is also important to supplement these data evaluating the shaping ability using up-to-date nondestructive methodologies, such as the micro-CT imaging system, in order to simulate clinical usage. In the present study, attempts were made to ensure the comparability of the groups by creating a homogenous and reliable baseline according to 3D quantitative data acquired by previously scanning all samples, which enhanced the internal validity of the method and reduced the anatomic bias that usually confounds the outcomes. Shaping ability was conducted by comparing only instruments with similar sequences and dimensions (i.e., HyFlex X NeoNiti systems and ProTaper Universal X ProTaper Gold systems). This is an important methodological aspect considering that differences in root canal preparation have been linked to the dimensions of the instruments. In fact, the present results corroborated those findings (Table 3). Although comparisons were performed between systems with remarkable differences (ProTaper Universal X ProTaper Gold) or similarities (HyFlex X NeoNiti) regarding NiTi alloy properties, no differences in the shaping outcomes were observed (Table 3), and the third null hypothesis was accepted. This result can be explained by the similar dimensions of the instruments, preparation protocols and, most importantly, the kinematics used in matched canal morphologies. The varied range of results observed in the groups can be explained by the minor differences in the anatomic irregularities of the root canal walls inherent to the maxillary molar teeth. Consequently, as would be expected, none of the preparation protocols was able to prepare all root canal walls. It is also important to highlight that, despite the fact that no difference was observed in the performed comparisons, the percentage of untouched walls in the canals prepared with the ProTaper instruments was higher than that of the thermomechanically treated systems, which can be explained by the differences in the morphology of the root canals before the experimental procedures (Table 3). In this study, canals were pair matched based on 3D anatomic parameters to allow the comparison of NiTi systems with similar sequences and dimensions. Therefore, this finding supports previous studies demonstrating that variations in canal geometry before shaping procedures had a greater effect on the changes that occurred during preparation than the instrumentation techniques. Finally, no instrument separation or significant transportation of the original canal pathway based on a qualitative evaluation of the 3D models was observed, which is in accordance with publications on root canal preparation with special NiTi alloy rotary instruments used by experienced clinicians following manufacturers’ protocols.

In the literature, it is not unusual to observe attempts to rank NiTi instruments based simply on their mechanical performance. The present study combined the physical properties and shaping ability of instruments with similar designs and/or alloys. It was demonstrated that, despite the differences observed among them regarding fatigue resistance and metallurgical properties, no difference was observed on their shaping ability (i.e., the main purpose from which these instruments have been developing). It means that, if instruments with comparable dimensions and/or preparation protocols were used in similar canal anatomies, it is likely that they behave similarly in terms of shaping outcome and safety even if they exhibit statistical differences in their physical properties. Further studies are needed to test this hypothesis by appraising other systems in different anatomic conditions, including counterfeiter and replicalike instruments recently launched in the marked.

Conclusion

Apart from differences in the mechanical tests and metallurgical characterization, systems with comparable instrument dimensions and preparation protocols (HyFlex X NeoNiti and ProTaper Universal X ProTaper Gold) showed similar percentage of untouched surface areas in the preparation of root canals of maxillary molars.

Authors: Emmanuel J. N. L. Silva, Jorge N. R. Martins, Carolina O. Lima, Victor T. L. Vieira, Francisco M. Braz Fernandes, Gustavo De-Deus, Marco A. Versiani

References:

- Bishop K, Dummer PM. A comparison of stainless steel Flexofiles and nickel-titanium NiTiFlex files during the shaping of simulated canals. Int Endod J 1997;30:25–34.

- Pettiette MT, Metzger Z, Phillips C, Trope M. Endodontic complications of root canal therapy performed by dental students with stainless-steel K-files and nickel-titanium hand files. J Endod 1999;25:230–4.

- Parashos P, Messer HH. Rotary NiTi instrument fracture and its consequences. J Endod 2006;32:1031–43.

- Sattapan B, Nervo GJ, Palamara JE, Messer HH. Defects in rotary nickel-titanium files after clinical use. J Endod 2000;26:161–5.

- McGuigan MB, Louca C, Duncan HF. The impact of fractured endodontic instruments on treatment outcome. Br Dent J 2013;214:285–9.

- Gavini G, Santos MD, Caldeira CL, et al. Nickel-titanium instruments in endodontics: a concise review of the state of the art. Braz Oral Res 2018;32:e67.

- Zupanc J, Vahdat-Pajouh N, Schafer E. New thermomechanically treated NiTi alloys - a review. Int Endod J 2018;51:1088–103.

- Plotino G, Grande NM, Mercade Bellido M, et al. Influence of temperature on cyclic fatigue resistance of ProTaper Gold and ProTaper Universal rotary files. J Endod 2017;43:200–2.

- Silva EJ, Muniz BL, Pires F, et al. Comparison of canal transportation in simulated curved canals prepared with ProTaper Universal and ProTaper Gold systems. Restor Dent Endod 2016;41:1–5.

- Weinert K, Petzoldt V. Machining of NiTi based shape memory alloys. Mater Sci Eng A Struct Mater 2004;378:180–4.

- Pfeifer R, Herzog D, Hustedt M, Barcikowski S. Pulsed Nd:YAG laser cutting of NiTi shape memory alloys—influence of process parameters. J Mater Process Technol 2010;210:1918–25.

- Pirani C, Iacono F, Generali L, et al. HyFlex EDM: superficial features, metallurgical analysis and fatigue resistance of innovative electro discharge machined NiTi rotary instruments. Int Endod J 2016;49:483–93.

- Pedullá E, Lo Savio F, Boninelli S, et al. Torsional and cyclic fatigue resistance of a new nickel- titanium instrument manufactured by electrical discharge machining. J Endod 2016;42:156–9.

- Aminsobhani M, Meraji N, Sadri E. Comparison of cyclic fatigue resistance of five nickel titanium rotary file systems with different manufacturing techniques. J Dent (Tehran) 2015;12:636–46.

- Gündoğar M, Özyürek T. Cyclic fatigue resistance of OneShape, HyFlex EDM, WaveOne Gold, and Reciproc Blue nickel-titanium instruments. J Endod 2017;43:1192–6.

- Nabavizadeh MR, Sedigh-Shams M, Abdolrasoulnia S. Cyclic fatigue life of two single file engine- driven systems in simulated curved canals. Iran Endod J 2018;13:61–5.

- Rubio J, Zarzosa JI, Pallares A. A comparative study of cyclic fatigue of 10 different types of endodontic instruments: an in vitro study. Acta Stomatol Croat 2019;53:28–36.

- Hülsmann M. Research that matters: studies on fatigue of rotary and reciprocating NiTi root canal instruments. Int Endod J 2019;52:1401–2.

- Rodrigues CS, Vieira VT, Antunes HS, et al. Mechanical characteristics of counterfeit Reciproc instruments: a call for attention. Int Endod J 2018;51:556–63.

- Silva E, Giraldes JF, de Lima CO, et al. Influence of heat treatment on torsional resistance and surface roughness of nickel-titanium instruments. Int Endod J 2019;52:1645–51.

- Silva E, Vieira VT, Belladonna FG, et al. Cyclic and torsional fatigue resistance of XP-endo Shaper and TRUShape instruments. J Endod 2018;44:168–72.

- International Organization for Standardization ISO 3630-1. Dental root canal instruments: part 1- files, reamers, barbed broaches, rasps, paste carriers, explorers and cotton broaches. Geneva, Switzerland: International Organization for Standardization; 1992.

- ASTM International. ASTM F2004217: Standard test method for transformation temperature of nickel-titanium alloys by thermal analysis. West Conshohocken, PA: American Society for Testing and Materials; 2004.

- Wu RC, Chung CY. Differential scanning calorimetric (DSC) analysis of rotary nickel-titanium (NiTi) endodontic file (RNEF). J Mater Eng Perform 2012;21:2515–8.

- De-Deus G, Belladonna FG, Silva EJ, et al. Micro-CT evaluation of non-instrumented canal areas with different enlargements performed by NiTi systems. Braz Dent J 2015;26:624–9.

- Gagliardi J, Versiani MA, de Sousa-Neto MD, et al. Evaluation of the shaping characteristics of ProTaper Gold, ProTaper NEXT, and ProTaper Universal in curved canals. J Endod 2015;41:1718–24.

- Kaval ME, Çapar ID, Ertas H. Evaluation of the cyclic fatigue and torsional tesistance of novel nickel-titanium rotary files with various alloy properties. J Endod 2016;42:1840–3.

- De-Deus G, Silva EJ, Vieira VT, et al. Blue thermomechanical treatment optimizes fatigue resistance and flexibility of the Reciproc files. J Endod 2017;43:462–6.

- Ninan E, Berzins DW. Torsion and bending properties of shape memory and superelastic nickel- titanium rotary instruments. J Endod 2013;39:101–4.

- De-Deus G, Simoes-Carvalho M, Belladonna FG, et al. Creation of well-balanced experimental groups for comparative endodontic laboratory studies: a new proposal based on micro-CT and in silico methods. Int Endod J 2020;53:974–85.

- Peters OA, Laib A, Gohring TN, Barbakow F. Changes in root canal geometry after preparation assessed by high-resolution computed tomography. J Endod 2001;27:1–6.

- Paqué F, Ganahl D, Peters OA. Effects of root canal preparation on apical geometry assessed by micro-computed tomography. J Endod 2009;35:1056–9.

- Belladonna FG, Carvalho MS, Cavalcante DM, et al. Micro-computed tomography shaping ability assessment of the new blue thermal treated reciproc instrument. J Endod 2018;44:1146–50.

- De-Deus G, Belladonna FG, Simoes-Carvalho M, et al. Shaping efficiency as a function of time of a new heat-treated instrument. Int Endod J 2019;52:337–42.

- Zuolo ML, Zaia AA, Belladonna FG, et al. Micro-CT assessment of the shaping ability of four root canal instrumentation systems in oval-shaped canals. Int Endod J 2018;51:564–71.