Influence of Kinematics on the Cyclic Fatigue Resistance of Replicalike and Original Brand Rotary Instruments

Abstract

Introduction: The aim of this study was to evaluate the cyclic fatigue resistance of 3 replicalike rotary instruments compared with their original brand systems using continuous rotation and optimum torque reverse (OTR) kinematics.

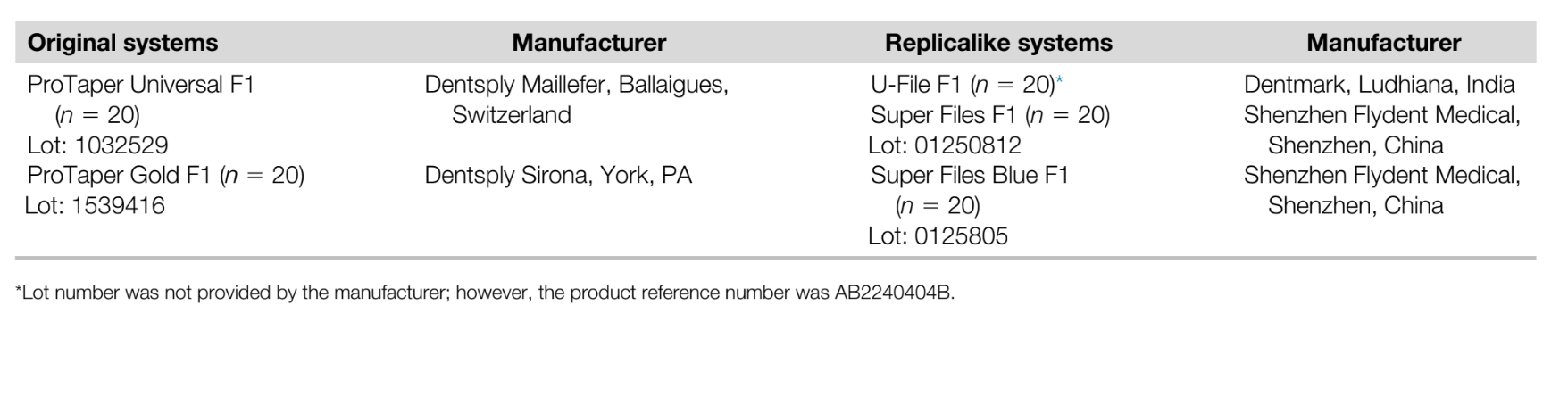

Methods: New F1 rotary instruments (n = 20 per group) from ProTaper Universal (Dentsply Maillefer, Ballaigues, Switzerland) and ProTaper Gold (Dentsply Maillefer) original brand systems were compared with 3 replicalike instruments (U-File [Dentmark, Ludhiana, India], Super Files [Shenzhen Flydent Medical, Shenzhen, China], and Super Files Blue [Shenzhen Flydent Medical]) regarding cyclic fatigue resistance. In each group, the selected instruments were randomly distributed into 2 subgroups (n = 10) according to the kinematics. In the rotary group (ROT), the instruments were activated with a continuous clockwise rotation (300 rpm, 1.5 Ncm), whereas in the OTR group, asymmetric oscillatory motion was performed setting the OTR function at 300 rpm and adjusting the torque limit at the minimum level using the TriAuto ZX2 motor (J Morita, Kyoto, Japan). The time to fracture was recorded and statistically compared according to the kinematics (ROT X OTR) and the instrument type (replicalike X original brand) using the independent sample t test (α = 0.05). Additionally, the metal alloy characterization of each system was performed by differential scanning calorimetry and energy-dispersive X-ray spectroscopy.

Results: Statistical analysis revealed significantly higher time to fracture for all rotary systems tested in OTR motion compared with continuous rotation (P ˂ .05) with a mean percentage increase ranging from 52.1% (ProTaper Gold) to 156.7% (U-File). The replicalike instruments showed a significantly higher time to fracture compared with the respective original brand instruments in either ROT or OTR motion (P ˂ .05). Replicas presented austenitic temperatures above the ones displayed by the original brands and an almost equiatomic ratio between nickel and titanium elements.

Conclusions: OTR motion significantly improved the fatigue resistance of both original and replicalike systems. The replicas showed higher cyclic fatigue resistance than original brand instruments and higher transition temperatures to the austenitic phase. (J Endod 2020;46:1136–1143.)

Preparation of the root canal system is recognized as being 1 of the most important stages in root canal treatment and includes the removal of vital and/or necrotic tissues from the root canal system along with infected root dentin1. Although this aim can be achieved by using different types of instruments and techniques, undoubtfully the development of nickel-titanium (NiTi) rotary systems resulted in a significant advancement in the mechanical preparation of the root canal space. NiTi rotary instruments have become popular to shape root canals because of their elasticity and cutting efficiency. However, in clinics, instrument separation still continues to be a major concern during root canal treatment, and even new instruments might demonstrate unexpected breakage on their first use.

Although instrument separation has been explained on the basis of both excessive torsion and cyclic fatigue, the latter has been more directly implicated with unexpected breakages of NiTi rotary instruments, probably because of some flaws near the surface such as machining grooves or subsurface defects created during the manufacturing process. The term cyclic fatigue is used to describe the breakage of NiTi instruments after continuous rotation in a curved canal and occurs as a result of the alternating tension compression cycles to which the instruments are subjected when flexed in the region of maximum curvature of the canal. Over the years, several improvements in NiTi instruments have been proposed in order to overcome these limitations. Advances in metallurgy and manufacturing processes have allowed the development of instruments that are more flexible and resistant to fracture because of their innovative design and heat treatments, but the type of motion has been also considered an important factor that may affect fatigue resistance.

Recently, optimum torque reverse (OTR) has been launched as an alternative kinematic for use with clockwise cutting rotary NiTi instruments in order to reduce instrument fatigue as well as the possibility of breakage. OTR motion was incorporated in a cordless motor (TriAuto ZX2; J Morita, Kyoto, Japan) and allows the continuous clockwise rotation of the instrument when a minimal load resistance is met. Once the present torque values are exceeded (trigger torque), the instrument automatically reverses rotation in the counterclockwise direction by 90° and then continues in the cutting direction for 180° until the torque becomes less than the set value. Preliminary findings demonstrated a significant improvement of cyclic fatigue resistance of different rotary instruments using OTR motion compared with continuous rotation.

Currently, many different brands of NiTi rotary instruments are available on the market. However, recently, several companies started to manufacture and/or distribute NiTi preparation systems very much like the original ones produced by well-known companies.

Considering that this is a new phenomenon in endodontics, the literature provides no terminology to appropriately describe this group of instruments; in the current study, they are referred to as replicalike systems. These replicalike systems are being commercialized worldwide by local distribution companies or via the Internet and usually have lower prices when compared with the original instruments. Both the manufacturer and distribution companies are legal in their own countries, and the instruments are usually marketed by well- known companies. To date, despite the fact that replicalike instruments are being sold worldwide and used on a daily basis, there is no scientific study evaluating their mechanical performance. Therefore, the purpose of the present study was to evaluate the cyclic fatigue resistance of 3 replicalike rotary instruments compared with their original brand systems using continuous rotation and OTR kinematics. Moreover, aiming to accomplish a comprehensive analysis of the results, a characterization of the rotary systems metal alloy of the tested systems was also performed by differential scanning calorimetry (DSC) and energy-dispersive X-ray spectroscopy. The null hypotheses to be tested were as follows: (1) there are no differences in cyclic fatigue resistance between continuous clockwise rotation and OTR motion and (2) there are no differences in cyclic fatigue resistance of original brand and replicalike instruments.

Materials and Methods

Replicalike and Original Brand Rotary Systems

One hundred brand new original and replicalike F1 rotary NiTi instruments (n = 20 per rotary system) were randomly selected (Table 1). Within the purpose of the present study, and independently of being presented under different names and brands, a replicalike instrument was defined as presenting

- the exact same number of instruments of the original brand system,

- the same instrument color coding of the original brand system, and

- the same or comparable instrument nomenclature of the original brand system (Figs. 1 and 2). All instruments were initially observed under a stereomicroscope at X13.6 (Opmi Pico; Carl Zeiss Surgical, Jena, Germany) to discard those with evident major deformations or defects.

Cyclic Fatigue Test

The cyclic fatigue resistance test was performed using a custom-made device that allowed a reproducible assessment of an instrument rotating loose inside a curved canal until fracture occurs. The block containing the artificial canal was connected to a main frame to which a mobile support for the handpiece was also connected, aiming to allow precise and reproducible placement of the instruments to the same depth inside the artificial canal. The artificial canal was created on a nontapered stainless steel tube with a 19-mm length composed of 3 segments. The initial and final straight segments are 7 mm and 3 mm in length, respectively. In between them, there is a curved segment (6-mm radius and 86° of curvature) measuring 9 mm in length with the position of maximum stress in the middle of the curvature length. The steel walls have a 1.3-mm thickness and an inner diameter of 1.4 mm.

In each group (Table 1), the 20 selected instruments were randomly distributed into 2 subgroups (n = 10) according to the kinematic: continuous rotation (the ROT group) or reciprocating OTR motion (the OTR group). In the ROT group, instruments were activated using the TriAuto ZX2 motor with a continuous clockwise rotation at 300 rpm and 1.5 Ncm torque by disabling the auto-stop and auto- reverse functions. In the OTR group, reciprocation motion was performed using the same motor set in the OTR function at 300 rpm and adjusting the torque limit at the minimum level in order to generate a reciprocating movement without any phase of continuous rotation according to Pèdulla et al.

All instruments were tested continuously using glycerin as the lubricant at room temperature until rupture occurred. The time to fracture was recorded in seconds with a digital chronometer and stopped when the file fracture was detected visually and/or audibly. The number of cycles to failure was not calculated considering that OTR motion is a mixed movement presenting an asymmetric oscillatory motion after triggering the initial preset torque value and was therefore not considered a continuous rotation. The size of the fractured segments was recorded only for the experimental control.

Energy-Dispersive Spectroscopy

Three new F1 instruments from each rotary system were previously cleaned by immersion in an acetone bath for 2 minutes and analyzed using a scanning electron microscope (Hitachi S-2400; Hitachi High-Tech Corporation, Tokyo, Japan) equipped with a Bruker Quantax energy-dispersive X-ray spectrometer (Bruker Corporation, Billerica, MA) with a light elements detector. The operative setting conditions were an acceleration voltage of 20 kW with a filament current of 3.1 A at a 25-mm working distance. An area of 400 mm X 400 mm was screened in each instrument. Data were assessed using Sigma Scan software (Systat Software Inc, San Jose, CA) in order to extract the proportions of nickel and titanium that constituted each file.

DSC

The DSC test was performed on 5-mm fragments with a weight of 15–20 mg removed from the active portion of the tested F1 instruments. Each fragment was submitted to a chemical etching bath composed of a mixture of 25% hydrofluoric acid, 45% nitric acid, and 30% distilled water for approximately 2 minutes; neutralized with distilled water; and weighed on an M-Power microbalance (Sartorius, Goettingen, Germany). Two aluminum pans (38 mg and 5 mm in diameter) were prepared, one with the fragment to be tested and the other one empty (control). The thermal cycle test was conducted on a differential scanning calorimeter (DSC 204 F1 Phoenix; Netzsch-Gerätebau GmbH, Selb, Germany) for approximately 1 hour 40 minutes. During that period, each fragment was submitted to temperatures ranging from 2150°C to 150°C, with holding temperature stabilizations of 2 minutes at both extremes. The test was conducted in a gaseous nitrogen atmosphere. The final data were assessed using Netzsch Proteus Thermal Analysis (Netzsch-Gerätebau GmbH) software from which the austenitic start and austenitic finish (Af) temperatures were extracted. Two tests were conducted in 2 different instruments in order to confirm the results. A third test was performed only if the initial tests were not within 10°C.

Statistical Analysis

The results showed a normal distribution (Shapiro-Wilk test, P ˃ .05) and statistical comparison of time to fracture between the ROT and OTR groups as well as between replicalike instruments and their respective original brand systems performed using the independent sample t test (SPSS v17.0 for Windows; IBM Corp, Armonk, NY). The null hypothesis was set at 5%. The initial sample size was defined as 10 instruments assigned to each subgroup according to the kinematics, aiming to subsequently perform a sample size calculation based on the initial results; however, because all experimental groups consistently revealed differences, no further tests were required.

Results

Cyclic Fatigue Test

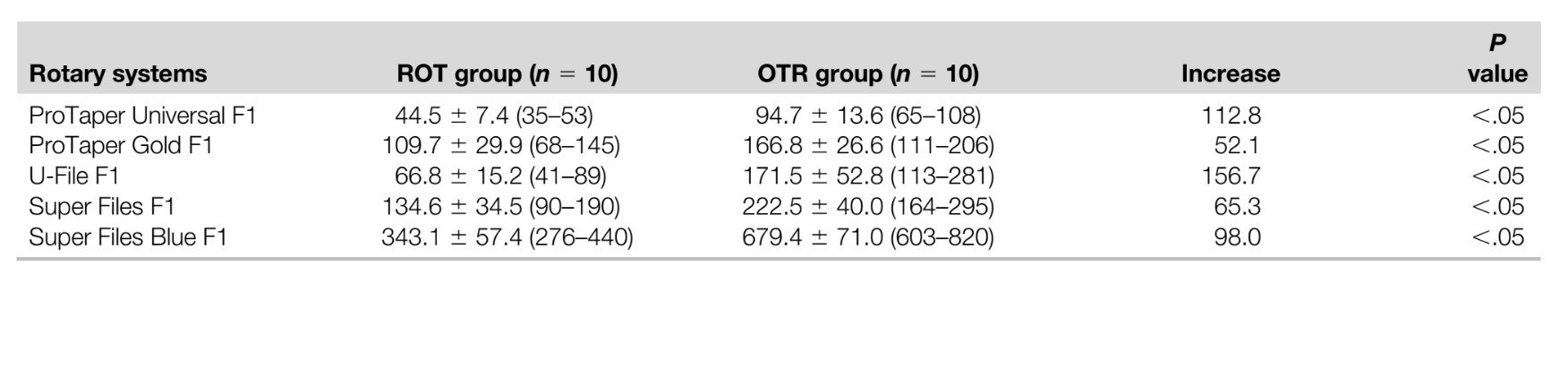

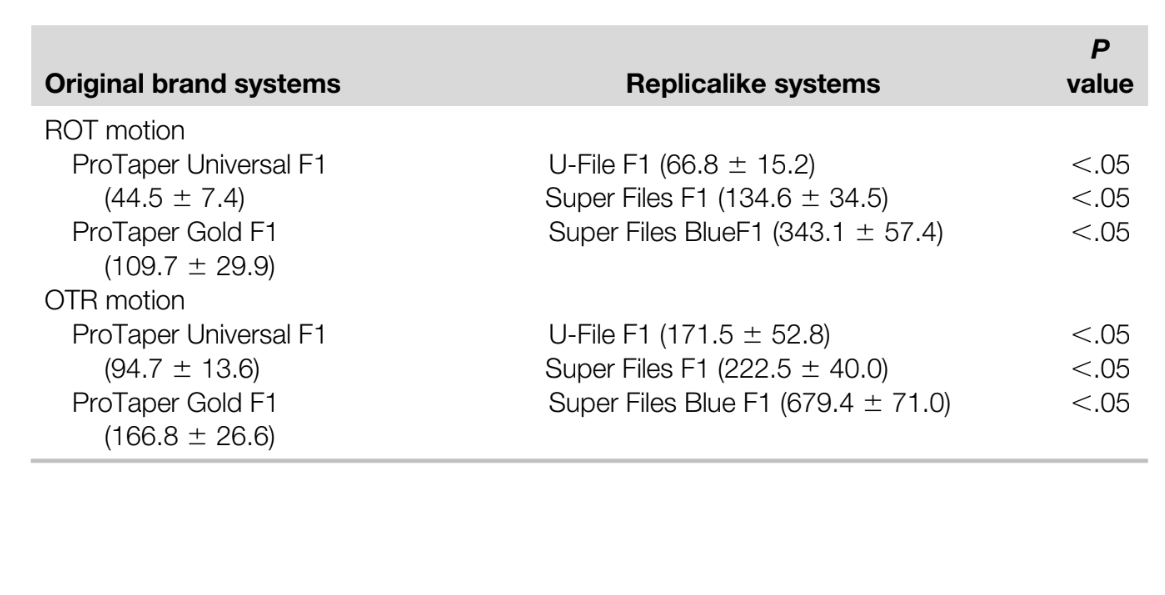

Statistical analysis revealed a significantly higher time to fracture for all rotary systems tested in OTR motion compared with continuous rotation (P ˂ .05), with a mean percentage increase ranging from 52.1% (ProTaper Gold; Dentsply Maillefer, Ballaigues, Switzerland) to 156.7% (U-File; Dentmark, Ludhiana, India) (Table 2). As for the comparison between NiTi systems, the replicalike instruments have shown a significantly higher time to fracture compared with the respective original brand instruments in either the ROT or OTR group (P ˂ .05) (Table 3). The mean sizes of the fractured segments were 7.20 ± 1.79 mm (Super Files Blue F1; Shenzhen Flydent Medical, Shenzhen, China), 7.45 ± 0.57 mm (U-File), 7.43 ± 0.72 mm (Super Files F1, Shenzhen Flydent Medical), 7.35 ± 0.51 mm (ProTaper Gold F1, Dentsply Maillefer), and 7.75 ± 0.30 mm (ProTaper Universal F1, Dentsply Maillefer) without statistical difference among the groups (P ˃ .05).

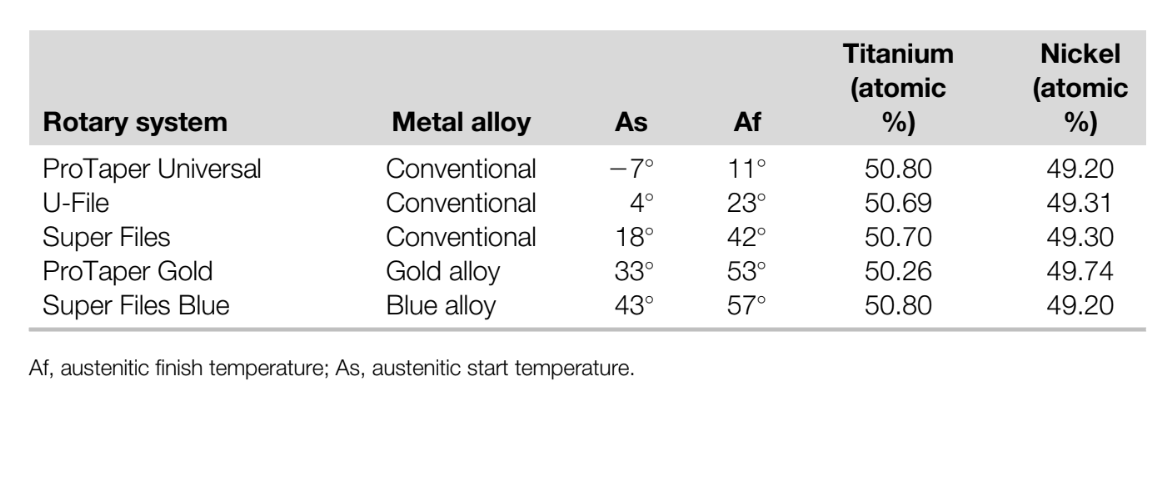

Energy-Dispersive Spectroscopy and DSC Tests

Table 4 summarizes the results of energy- dispersive spectroscopy and DSC tests. All tested instruments revealed an almost equiatomic ratio between nickel and titanium elements. All replicalike instruments showed austenitic transformation temperatures above the ones of the original instruments. The only F1 instrument with an Af transformation temperature below room temperature was the ProTaper Universal (Dentsply Maillefer) (Af: 11°C), whereas the highest value was observed with the Super Files Blue (Af: 57°C).

Discussion

Since the first NiTi rotary system was developed for root canal preparation, more than 160 mechanical systems were launched on the market. At first, all of them were produced in well-developed countries in which the dedicated technology was available.

However, more recently, a new phenomenon has been observed. Factories in major emerging economic countries in East Asia, such as China and India, are thriving by producing dental goods for the entire world. The main reasons for that have been attributed to the lower manufacturing cost, the cheaper labor, the higher production capability in less time, and the easier market expansion opportunities. On the other hand, despite the fact that there are well-known brands making products that are regarded as high quality and that command high prices, there also has been a demand for low-quality products in Western countries, creating an overall perception that some of these products are made out of shoddy materials. Following this trend, dental companies also based in these countries started to manufacture and sell endodontic instruments, including rotary and reciprocating NiTi systems. Although new instruments with innovative designs have been produced, there are also systems that copy or imitate the physical appearance of other well- known products but do not copy the brand name or logo of a trademark (named herein as replicalike systems). Unfortunately, the nonexistence of international specifications to guide the production of NiTi instruments for root canal preparation does not allow for imposing standards for quality control and mechanisms to supervise the implementation of regulatory tools and assessment criteria for regulatory quality of these products.

Consequently, clinicians are often unaware of the risks they incur by buying products for which there is no literature available regarding their metallurgical characteristics and mechanical behavior. Therefore, considering the increasing number of replicalike systems available on the market and the high frequency of rotary instrument separation reported in the literature, this study presents preliminary but original results on the fatigue resistance of 3 replicalike instruments compared with their well-known original brand systems, suggesting an alternative approach to increase their safety in use.

In this study, the time to fracture during the cyclic fatigue test was compared when the selected instruments were used in continuous rotation or OTR motion. Although the amount of torque needed to perform a cyclic fatigue test has never been established, during the tests in the OTR mode, the trigger torque was set to a low value (0.2 N), as reported in previous studies, to ensure that the motor was performing only OTR reciprocating motion without any continuous rotation phase. This is an important methodological aspect because if OTR motion begins at different times for each instrument of the same brand and also from different brands, data would not have been directly comparable because the tests would not have been standardized. On the other hand, when continuous rotation was tested, the torque limit was set not only to mimic their clinical application but also to follow the manufacturers’ recommendations (1.5 N), disabling auto-reverse and auto-stop functions to avoid reverse or stopping of the rotation during the test. According to the results, the use of OTR motion significantly increased the time to fracture of all systems (Table 2); therefore, the first null hypothesis was rejected. Although the percentage increase of the time to fracture varied from 52.1%–112.8%, in the original brands, it ranged from 65.3%–156.7% in the replicalike systems when used in OTR motion (Table 2). According to a previous study, asymmetric oscillatory motion provides a small release movement, opposed to the cutting direction, which may retard the crack propagation increasing the fatigue resistance of the instruments, which helps to explain the present results. Therefore, OTR reciprocating motion can be suggested as an alternative approach to continuous rotation, aiming to improve the safety use of NiTi rotary instruments, mostly when no scientific data are available regarding the mechanical behavior of the system.

Interestingly, the replicalike instruments showed a significantly higher time to fracture compared with the respective original instruments in either ROT or OTR motions (Table 3); therefore, the second null hypothesis was rejected. Because no information is available in the literature or from the manufacturers regarding the replicalike instruments, the interpretation of the present results must be made with caution. First of all, it is important to notice that the tested instruments (F1) of both the original (Fig. 1) and replicalike (Fig. 2) systems showed similar designs regarding tip size, taper, and cross-sectional shape. Therefore, these results might be related to the martensitic-austenitic transformation at a specific temperature. It is well-known that a fully austenitic sample of NiTi alloy has lower cyclic fatigue resistance than a partially martensitic one depending on the instruments’characteristics. Considering the metallurgical tests performed in the present study, the almost equiatomic characteristics of all tested instruments seem to exclude the proportions of titanium and nickel as a possible source of difference observed in their mechanical behavior. However, the results of the DSC test may explain the differences observed among the tested instruments. The presence of the Af temperature below the room temperature in the ProTaper Universal instrument gives it a total austenitic crystalline phase constitution, whereas the higher Af temperature observed in the Super Files instrument compared with the ProTaper Universal and U-File instruments indicates that its martensitic characteristics are still present below the room temperature, which explains its higher cyclic fatigue resistance results. Regarding the thermo-treated instruments and assuming a true blue treatment on the Super Files Blue system (not confirmed or reported by the manufacturer), its higher time to fracture compared with the ProTaper Gold instruments would be expectable and was confirmed by its superior Af temperature, a similar effect also observedwith the conventional alloy systems (Table 4).

Although the fracture mechanisms have not yet been completely understood, 2 types of NiTi instrument modes of failure have beenidentified and described as torsional or cyclic fatigue failures. Regarding the cyclic fatigue mode of failure, it tends to occur when a file is subjected to repetitive cycles of compression and tension, which happens in root canals with severe curvatures or as result of low-intensity stress tension applied for a long period of time, which could correspond to overuse as well. The wear induced by the tension and compression cycles may lead to instrument fracture, with some studies pointing out that this phenomenon is responsible for 93% of instrument separation. In order to mimic thetension and compression effect on the instrument’s metal alloy in a laboratory- controlled environment, different cyclic fatigue resistance tests were developed. In this type of experimental setup, the instrument to betested is mounted in a stabilized handpiece and made to rotate freely in an artificial canal with predefined characteristics and under specific conditions until the instrument ruptures. It allows for different factors to be isolated and tested individually without interference from other variables, increasing the internal validity and reproducibility of the method, which allows better comprehension of the resistance behavior of instruments.

Taking this into consideration, a recent editorial stating that the results of cyclic fatigue tests are useless for clinicians and a review concluding that “fatigue resistance tests conducted under room temperature should be regarded as having little meaning and thus as outdated” are highly questionable because tests conducted at a body temperature showed a significant low number of cycles to fracture. These conclusions are questionable because the cyclic fatigue tests at room temperature cannot be considered outdated; on the contrary, these tests, at any temperature, have an unquestionable validity. These tests make it possible to identify very clearly the role that small changes in temperature may have on the working behavior of the instruments, taking into account the more or less significant structural changes that may occur with such temperature variations. At most, the review author may question the clinical relevance of conducting it at a specific temperature that may or may not be related with a specific clinical condition.

It is important to highlight that the majority of instruments submitted to cyclic fatigue tests under body temperature suffer a decrease of their fatigue resistance not because of the temperature itself but rather because the increased temperature transmitted from the warmed artificial canal to the metal alloy of the instrument, depending on the instrument’s transformation phase range, may change its crystalline phase to austenitic characteristics, which, independent of being thermo-treated or not, will lead to a decrease in the number of cycles to fracture. It is also important to highlight that there is no evidence to support that the alloy crystalline changes induced by the passage of temperature from the canal to the instrument on a body temperature cyclic fatigue test, which usually takes several minutes and allows the temperature of the instrument to rise and stabilize, is the same as the clinical condition in which the instruments contact the root canal walls for just a few seconds. Additionally, in clinics, it must be taken into consideration the presence of an irrigant solution, commonly used under room temperature, as well as the thermal insulating efficiency of the dentin, which may affect the temperature within the root canal space. Therefore, considering the assumption that the cyclic fatigue test under body temperature mimics better the clinical condition lacks validation, the room temperature was chosen to perform the cyclic fatigue test in this study once that is the real temperature in which the instruments are stored and used in clinics.

Another literature controversy on the cyclic fatigue topic is the use of a dynamic model opposed to the static model, aiming to more closely mimic the clinical setting by using the in-and-out repetitive movement of the instrument in order to distribute the stress applied to the instrument along a larger area, avoiding the localized load, and increasing the number of cycles to failure. Actually, thedynamic model has been associated with a lower internal validity when compared with the static model because it might be difficult to keep the instrument in a reproductive trajectory, especially when comparing instruments with different geometric features. Although there is the possibility of standardization of speed and amplitude of the axial movement in the dynamic model, these variables are operator dependent and not possible to be properly reproduced in clinics. Besides, considering OTR motion, the dynamic model would also add another drawback once the instruments at this kinematic mode could rotate instead of performing a pure reciprocating motion at the straight segment of the artificial canal.

Therefore, in order to overcome the limitations of the dynamic model, which seems to be more technique sensitive, and to minimize confounding causes by other mechanisms of instrument separation apart from cyclic fatigue, a static model was chosen in the present study. This method allows the isolation of the independent variables (continuous rotation and OTR motion), minimizing other possible confounding variables. Additionally, the similar length of the fracture segments confirmed the correct placement of the instruments into the testing device, confirming the reproducibility of this model and allowing a reliable mechanical comparison between replicalike and original brand instruments. Obviously, as it happens with all in vitro testing studies, the present results cannot be directly extrapolated to the clinical situation. Further research on the mechanical properties, the metal alloy, the geometric characteristics, the shaping ability, and the cutting efficiency of other replicalike and counterfeit instruments must be performed in order to understand their safety in use compared with the original brand systems, but it would also be of benefit for the validation of different kinematics, such as OTR motion, as an alternative approach to the continuous clockwise rotation.

Conclusions

Under the conditions of the present study, the use of asymmetric oscillatory motion provided by the OTR function resulted in superior cyclic fatigue resistance of all tested systems when compared with continuous clockwise movement. Moreover, the replicalike F1 instruments have shown a significantly higher resistance to cyclic fatigue compared with the original brands in either OTR or rotary kinematics.

Authors: Jorge N. R. Martins,Emmanuel João Nogueira Leal Silva, Duarte Marques, António Ginjeira, Francisco Manuel Braz Fernandes, Gustavo De Deus, Marco Aurélio Versiani

References:

- Hülsmann M, Peters OA, Dummer PM. Mechanical preparation of root canals: shaping goals, techniques and means. Endod Topics 2005;10:30–76.

- Peters OA. Current challenges and concepts in the preparation of root canal systems: a review. J Endod 2004;30:559–67.

- Versiani MA, Steier L, De-Deus G, et al. Micro–computed tomography study of oval-shaped canals prepared with the Self-adjusting File, Reciproc, WaveOne, and Protaper Universal systems. J Endod 2013;39:1060–6.

- Parashos P, Messer HH. Rotary NiTi instrument fracture and its consequences. J Endod 2006;32:1031–43.

- Arens FC, Hoen MM, Steiman HR, Dietz GC Jr. Evaluation of single-use rotary nickel-titanium instruments. J Endod 2003;29:664–6.

- Pèdulla E, Corsentino G, Ambu E, et al. Influence of continuous rotation or reciprocation of optimum torque reverse motion on cyclic fatigue resistance of nickel-titanium rotary instruments. Int Endod J 2018;51:522–8.

- Shen Y, Haapasalo M, Cheung GS, Peng B. Defects in nickel-titanium instruments after clinical use. Part 1: Relationship between observed imperfections and factors leading to such defects in a cohort study. J Endod 2009;35:129–32.

- Sattapan B, Nervo GJ, Palamara JE, Messer HH. Defects in rotary nickel-titanium files after clinical use. J Endod 2000;26:161–5.

- Gambarini G, Piasecki L, Miccoli G, et al. Classification and cyclic fatigue evaluation of new kinematics for endodontic instruments. Aust Endod J 2019;45:154–62.

- Gambarini G, Rubini AG, Al Sudani D, et al. Influence of different angles of reciprocation on the cyclic fatigue of nickel-titanium endodontic instruments. J Endod 2012;38:1408–11.

- J Morita Corporation. TriAuto ZX2 Operational Instructions. Available at: https://www.morita. com/cms/files/TR-ZX2-US_Operation_USA_K322-80002-500_20180406_en.pdf. Accessed March 6, 2020.

- Silva EJ, Vieira VT, Belladonna FG, et al. Cyclic and torsional fatigue resistance of XP-endo Shaper and TRUShape instruments. J Endod 2018;44:168–72.

- Silva EJ, Vieira VT, Hecksher F, et al. Cyclic fatigue using severely curved canals and torsional resistance of thermally treated reciprocating instruments. Clin Oral Investig 2018;22:2633–8.

- Gavini G, Santos MD, Caldeira CL, et al. Nickel-titanium instruments in endodontics: a concise review of the state of the art. Braz Oral Res 2018;32:e67.

- Roy K, Blomqvist H, Clark C. Economic Development in China, India and East Asia: Managing Change in Twenty First Century. 1st ed. Cheltenham, UK: Edward Elgar Publishing Inc; 2012.

- Iqbal MK, Kohli MR, Kim JS. A retrospective clinical study of incidence of root canal instrument separation in an endodontics graduate program: a PennEndo database study. J Endod 2006;32:1048–52.

- Tzanetakis GN, Kontakiotis EG, Maurikou DV, Marzelou MP. Prevalence and management of instrument fracture in the postgraduate endodontic program at the Dental School of Athens: a five-year retrospective clinical study. J Endod 2008;34:675–8.

- Tokita D, Ebihara A, Miyara K, Okiji T. Dynamic torsional and cyclic fracture behavior of ProFile rotary instruments at continuous or reciprocating rotation as visualized with high-speed digital video imaging. J Endod 2017;43:1337–42.

- Zhou H, Peng B, Zheng Y. An overview of the mechanical properties of nickel–titanium endodontic instruments. Endod Topics 2013;29:42–54.

- Herold KS, Johnson BR, Wenckus CS. A scanning electron microscopy evaluation of microfractures, deformation and separation in EndoSequence and Profile nickel-titanium rotary files using an extracted molar tooth model. J Endod 2007;33:712–4.

- Kuhn G, Jordan L. Fatigue and mechanical properties of nickel-titanium endodontic instruments. J Endod 2002;28:716–20.

- Hülsmann M. Research that matters: studies on fatigue of rotary and reciprocating NiTi root canal instruments. Int Endod J 2019;52:1401–2.

- Hülsmann M, Donnermeyer D, Schafer E. A critical appraisal of studies on cyclic fatigue resistance of engine-driven endodontic instruments. Int Endod J 2019;52:1427–45.

- Thompson SA. An overview of nickel-titanium alloys used in dentistry. Int Endod J 2000;33:297–310.

- de Vasconcelos RA, Murphy S, Carvalho CA, et al. Evidence for reduced fatigue resistance of contemporary rotary instruments exposed to body temperature. J Endod 2016;42:782–7.

- Huang X, Shen Y, Wei X, Haapasalo M. Fatigue resistance of nickel-titanium instruments exposed to high-concentration hypochlorite. J Endod 2017;43:1847–51.

- Kelesx A, Eymirli A, Uyanik O, Nagas E. Influence of static and dynamic cyclic fatigue tests on the lifespan of four reciprocating systems at different temperatures. Int Endod J 2019;52:880–6.

- Plotino G, Grande NM, Mercade Bellido M, et al. Influence of temperature on cyclic fatigue resistance of ProTaper Gold and ProTaper Universal rotary files. J Endod 2017;43:200–2.

- Li UM, Lee BS, Shih CT, et al. Cyclic fatigue of endodontic nickel titanium rotary instruments: static and dynamic tests. J Endod 2002;28:448–51.