Comparison of fve rotary systems regarding design, metallurgy, mechanical performance, and canal preparation—a multimethod research

Abstract

Objectives: To compare the design, metallurgy, mechanical performance, and canal preparation of 5 rotary systems.

Material and methods: A total of 735 25-mm NiTi instruments (sizes 0.17[0.18]/.02v, 0.20/.04v, 0.20/.07v, 0.25/.08v, 0.30/.09v) from ProTaper Gold, ProTaper Universal, Premium Taper Gold, Go-Taper Flex, and U-File systems were compared regarding overall geometry and surface finishing (stereomicroscopy and scanning electron microscopy), nickel and titanium ratio (energy-dispersive spectroscopy), phase transformation temperatures (differential scanning calorimetry), mechanical performance (torsional and bending tests), and unprepared canal surface (micro-CT). One-way ANOVA and Mood’s median tests were used for statistical comparisons with a significance level set at 5%.

Results: Stereomicroscopic analysis showed more spirals and high helical angles in the Premium Taper Gold system. All sets of instruments had symmetrical spirals, no radial lands, no major defects, and an almost equiatomic ratio between nickel and titanium elements, while differences were observed in their tips’ geometry and surface finishing. At room temperature (20 °C), DSC test revealed martensitic characteristics for ProTaper Gold and Go-Taper Flex, and mixed austenite plus R-phase for the Premium Taper Gold, while ProTaper Universal and U-Files had full austenitic characteristics. Overall, larger instruments had higher torque resistance and bending load values than smaller ones, while a lack of consistency and mixed values were observed in the angle of rotation. The 0.25/.08v and 0.30/.09v instruments of ProTaper Universal and U-File had the highest maximum torques, the lowest angles of rotation, and the highest bending loads than other tested systems (P < .05). No significant difference was noted regarding the untouched root canal walls after preparation with the tested systems (P > .05).

Conclusions: Although differences observed in the overall geometry and phase transformation temperatures have influenced the results of mechanical tests, unprepared canal surface areas were equivalent among systems.

Clinical relevance: Root canal preparation systems with similar geometries might present different mechanical behaviors but equivalent shaping ability.

Introduction

The advent of nickel-titanium (NiTi) rotary systems for root canal preparation provided clinicians with instruments with superelasticity and a greater capacity to maintain the original canal pathway when compared to conventional hand files. However, an intense twisting stress exceeding 8% strain applied to NiTi alloy over a short period over the instrument may lead to its plastic deformation and unexpected fracture. The mechanism most often associated with this occurrence is torsional failure which, in turn, is mainly caused by taper lock, accumulation of debris into the flutes, and the lock of the instrument’s tip into a narrow canal while the shank continues to rotate. Throughout the years, manufacturers have tried to improve the mechanical performance of rotary NiTi instruments by changing some of their characteristics, including modifications in the cross-sectional geometry, helical angle, number of blades, surface finishing, and alloy crystallographic arrangement. Another approach to reduce the stress over the instrument and, consequently, reduce fracture rate is the use of multiple instruments in a specific sequence. Most of rotary NiTi systems currently available are composed of 3 or more instruments, each one of them having different characteristics and specific values of torque and speed determined by the manufacturers to improve their safety in use. In a clinical environment, it is the combination of all of these factors that will influence the performance of rotary instruments during mechanical preparation of root canals.

ProTaper Universal (PTU; Dentsply Maillefer, Ballaigues, Switzerland) is an example of a long-lasting multiple-file rotary system made of conventional NiTi alloy, which is still available today. More recently, its manufacturer launched the ProTaper Gold (PTG; Dentsply Maillefer), a new version of this system, in which the instruments have a similar design, but the alloy has been thermomechanically treated, resulting in an improved fatigue resistance. Throughout the years, other companies developed systems that imitate the physical appearance of the PTU instruments, such as the case with Premium Taper Gold (Waldent, Shenzhen, China), Go-Taper Flex (Access, Shenzhen, China), and U-File (Dentmark, Ludhiana, India), and, recently, some studies provided important information about their safety, but clinicians are still unaware of the risks involved in using products with no scientific background.

Regardless of the aforementioned advancements, current technology for mechanical preparation still fails to debride all root canal walls, leaving untouched fins or recesses that may harbor residual bacterial biofilms and may serve as a potential cause of persistent infection and poor treatment outcome. Therefore, an in-depth analysis including the NiTi instruments that compose each rotary system should include the multiple analysis of all of these variables following a previously advocated multimethod research concept. The present study aims to fill in a gap in the literature by evaluating the full system of root canal preparation instruments of PTU (Dentsply Maillefer), PTG (Dentsply Maillefer), Premium Taper Gold (Waldent), Go-Taper Flex (Access), and U-File (Dentmark) systems using the multimethod research to assess the design, metallurgy, mechanical performance, and canal preparation. The null hypotheses to be tested were that there are no differences among instruments regarding their (i) mechanical performance and (ii) shaping ability.

Material and methods

A total of 735 25-mm NiTi instruments (sizes 0.17[0.18]/0.02v, 0.20/0.04v, 0.20/0.07v, 0.25/0.08v, and 0.30/0.09v) of 5 different rotary systems (two made of conventional NiTi alloy [PTU (Lot 1032529) and U-File (Lot AB2240404B)] and three thermal treated [PTG (Lot 1523909), Premium Taper Gold (Lot 201808), and Go-Taper Flex (Lot 17110103)]) were selected and comparisons were made regarding design, metallurgy, mechanical performance, and canal preparation.

Instruments’ design

Six randomly selected instruments from each type were inspected under stereomicroscopy (× 3.4 and × 13.6 magnifications; Opmi Pico, Carl Zeiss Surgical, Germany) and evaluated regarding (a) the number of active blades (in units); (b) the helical angle by taking the mean measurements of the 6 most coronal angles of the active blade, assessed in triplicate; and (c) the distance (in mm) from the 3 measuring lines marked at the non-cutting part of the instruments to the tip using a digital caliper (0.01-mm resolution; Mitutoyo, Aurora, IL, USA). Measurements were made in triplicate, averaged, and considered discrepant if values were higher than 0.1 mm from the reference line position; and (d) the presence of defects or deformations such as missed, twisted, or distorted blades. The same instruments were then inspected under conventional scanning electron microscopy (SEM) (× 100 and × 500 magnifications; S-2400, Hitachi, Tokyo, Japan) to evaluate (a) the symmetry of the spirals in their active blades (symmetrical or asymmetrical; with or without radial lands); (b) tip geometry (active or non-active); (c) cross-sectional shape; (d) marks produced on the surface by the machining process; and (e) minor deformations or defects.

Metallurgical characterization

Semi-quantitative elemental analysis was done by energy-dispersive X-ray spectroscopy and scanning electron microscopy (EDS/SEM) at a 25-mm distance on the surface (400 µm2) of 3 instruments of each type using a SEM device (20 kV and 3.1A; S-2400, Hitachi) connected to a EDS detector (Bruker Quantax, Bruker Corporation, Billerica, MA, USA) with a dedicated software with ZAF correction (Systat Software Inc., San Jose, CA, USA). Differential scanning calorimetry (DSC analysis; DSC 204 F1 Phoenix; Netzsch-Gerätebau GmbH, Selb, Germany) was used to assess the metallurgical features of the instruments. This test was carried out on a 3- to 5-mm fragment (7 to 10 mg) acquired from the coronal active portion of 2 different 0.20/0.07v instruments of each system, according to the American Society for Testing and Materials guideline. Firstly, samples were submitted to a chemical etching bath (45% nitric acid, 30% distilled water, and 25% hydro-fluoric) for 2 min, and then mounted in an aluminum pan, with an empty pan serving as control. Thermal cycles were performed under a gaseous nitrogen (N2) atmosphere with temperatures ranging from 150 to − 150 °C (cooling/heating rate: 10 K/min). DSC charts were created (Netzsch Proteus Thermal Analysis software; Netzsch-Gerätebau GmbH) for the visual assessment of the transformation temperatures. In each group, DSC test was performed twice in order to confirm the results.

Mechanical tests

The mechanical performance of all instruments in each system was evaluated by torsional and bending resistance tests according to ANSI/ADA Nº28-2002 and ISO3630- 3631:2008 international specifications. The 0.20/0.07v instrument was used as reference for sample size calculation based on the highest difference observed among systems after the 6 initial measurements of each test. Effect size calculation for the maximum torque (0.26 ± 0.18; U-File vs Go-Taper Flex), angle of rotation (410.5 ± 226.6; Premium Taper Gold vs Go-Taper Flex), and bending load test (356.5 ± 188.3; U-File vs Premium Taper Gold), with 80% power and an alpha-type error of 0.05, resulted in 9, 6, and 6 instruments, respectively, to observe differences among systems. In order to counter-balance that sample size calculation was not performed for the other instruments’ sizes, a total of 10 instruments were set for each test.

Before each test, the selected instruments were visually inspected under stereomicroscopy (× 13.6 magnification) and no deformation or defects were detected. In the torsional test, each instrument was clamped in its apical 3 mm and rotated clockwise on a constant speed (2 rotations/min) until fracture (TT100 Odeme Dental Research, Luzerna, Santa Catarina, Brazil). Then, maximum torque (in N.cm) and angle of rotation (in degrees) prior to fracture were calculated. For the bending resistance test, instruments were firstly mounted in the motor file holder which was positioned at 45° to the floor. Then, their apical 3 mm was attached to a wire connected to a universal testing machine (Instron EMIC DL-200 MF, São José dos Pinhais, Brazil), set at 15 mm/ min constant speed and 20 N load, until a 45° displacement occurs. The maximum load for displacement was recorded in gram/force (gf).

Root canal preparation

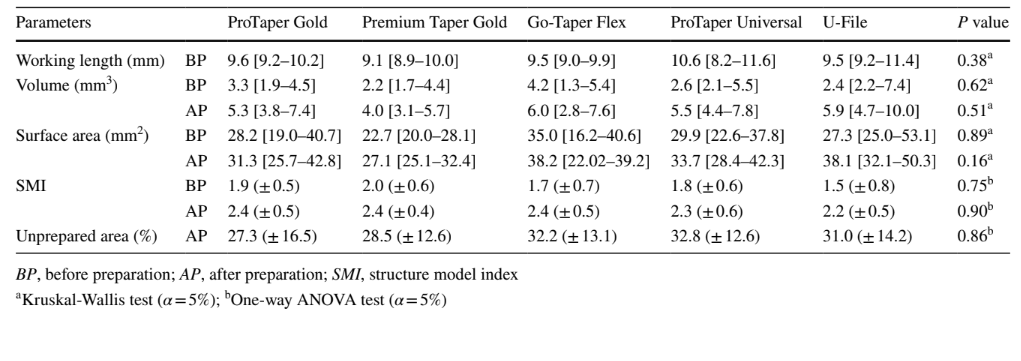

After approval of this research protocol (#CE202003) by the local Ethics Committee, one-hundred, two-rooted, mandibular molars with fully formed apices were randomly selected from a pool of extracted teeth and imaged at 19 µm (pixel size) with the SkyScan 1174v.2 micro-CT system (Bruker-microCT, Kontich, Belgium) set at 50 kV, 800 mA, rotation of 180° with steps of 0.6°, using a 1-mm-thick aluminum filter. The acquired projections were reconstructed using standardized parameters for smoothing (3), attenuation coefficient (0.01–0.15), beam hardening (15%), and ring artifact (3) corrections (NRecon v.1.6.9; Bruker-microCT). CTAn v.1.14.4 software (Bruker-microCT) was used to create three-dimensional (3D) models of the internal anatomy of each tooth, which were evaluated regarding canal configuration (CTVol v.2.2.1 software; Bruker-microCT). Then, morphometric parameters of root canals, including length, volume, surface area, and structure model index, were calculated from the cementoenamel junction level to the apex (CTAn v.1.14.4 software; Bruker-microCT). Based on these measurements, specimens were matched to create 5 groups of 4 teeth, in a total of 55 root canals. After checking the normality (Shapiro–Wilk test) and homoscedasticity (Levene’s test) of the parameters (P > 0.05; one-way ANOVA test), the homogeneity of the groups was confirmed. Then, each set of teeth with anatomically matched canals (n = 11) was randomly assigned to 1 of the 5 experimental groups according to the preparation protocol with PTG, Premium Taper Gold, Go-Taper Flex, PTU, and U-File systems.

Conventional access cavities were prepared and apical patency confirmed with a size 10 K-file (Ready Steel; Dentsply Maillefer). Glide path was performed with a size 15 K-file (Ready Steel; Dentsply Maillefer) at the working length (WL), established 0.5 mm from the foramen. Shaping procedure was performed up to the WL with the instruments adapted to a 6:1 angle handpiece (Sirona Dental Systems GmbH) rotating in a continuous clockwise direction (VDW Silver; VDW GmbH) with gentle in-and-out motion strokes, according to the manufacturers’ directions. After 3 strokes, the instrument was removed and cleaned and the procedure repeated until it reached the WL. Mesial canals were sequentially prepared with 0.17[0.18]/0.02v, 0.20/0.04v, 0.20/0.07v, and 0.25/0.08v instruments, while distal canals were further enlarged with a 0.30/0.09v instrument. One instrument was used for 2 canals and then discarded. After each step, irrigation was performed with a total of 15 mL of 2.5% NaOCl per canal using a disposable syringe fitted with a 30-G NaviTip needle (Ultradent, South Jordan, UT) positioned 1 mm from the WL. A final irrigation was accomplished with 5 mL of 17% EDTA and 5 mL of distilled water. Chemomechanical preparations were performed by a single operator with large experience in using rotary systems in clinics. Then, root canals were slightly dried (ProTaper Gold paper points; Dentsply Maillefer) and a final micro-CT scan and reconstruction were carried out as previously mentioned.

Color-coded models of co-registered pre- and post- operative models of the roots and root canals (3D Slicer 4.3.1 software; http://www.slicer.org) were rendered (CTAn v.1.14.4; Bruker-microCT) for qualitative comparison of groups (CTVol v.2.2.1; Bruker-microCT), while quantita- tive evaluation was done by calculating post-operative morphometric (volume, surface area, and structure model index) using CTAn v.1.14.4 software (Bruker-microCT). Then, the percentage of untouched canal walls was determined by the formula (Au/Ab) × 100, in which Au is the unprepared canal area and Ab is the canal area before preparation. All the analyses were performed by an examiner blinded to the shaping protocols.

Statistical analysis

The Shapiro–Wilk test was used to evaluate the normality of the data. Non-Gaussian distribution data were evaluated with nonparametric Mood’s median test, while normal distributed results were compared with one-way ANOVA and post hoc Tukey tests. Results were summarized using either mean and standard deviation or median and interquartile range depending on sample distribution with a significance level set at 5% (SPSS v22.0 for Windows; SPSS Inc., Chicago, IL, USA).

Results

Instruments’ design

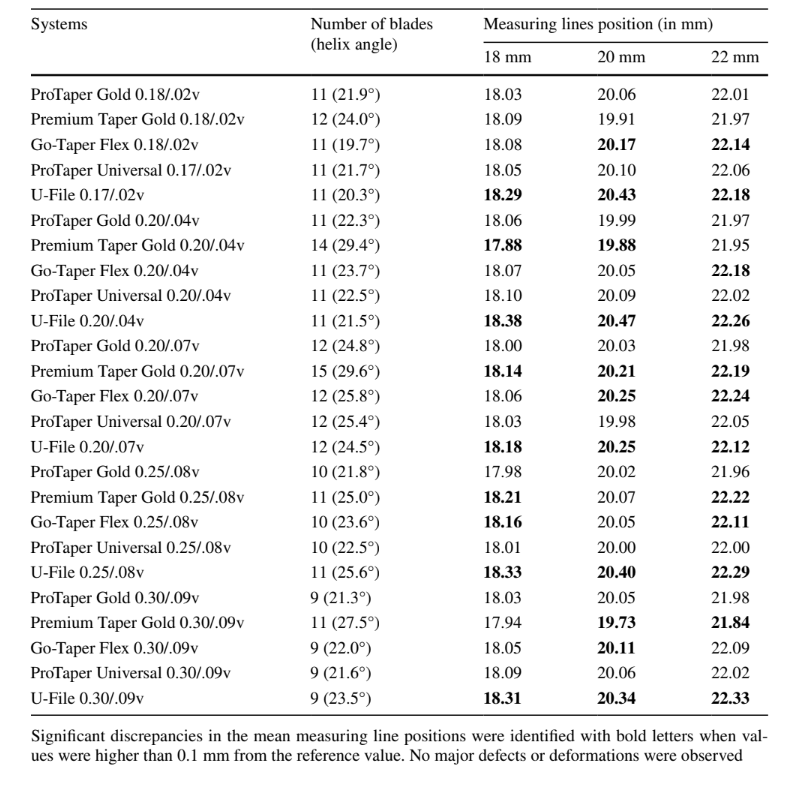

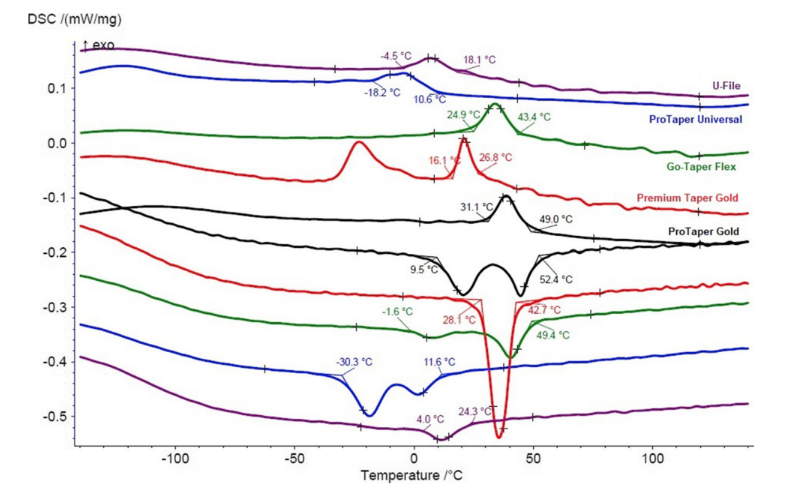

The instrument stereomicroscopic inspection showed that Premium Taper Gold system usually had 1 to 3 more spirals and superior helical angles (⁓8°) than the other tested systems, which were quite similar regarding these aspects (Table 1). Measuring line positions were consistent in the PTG and PTU instruments, while in the remaining systems discrepancies could be observed, with all U-File instruments presenting deviations higher than 0.1 mm (Table 1).

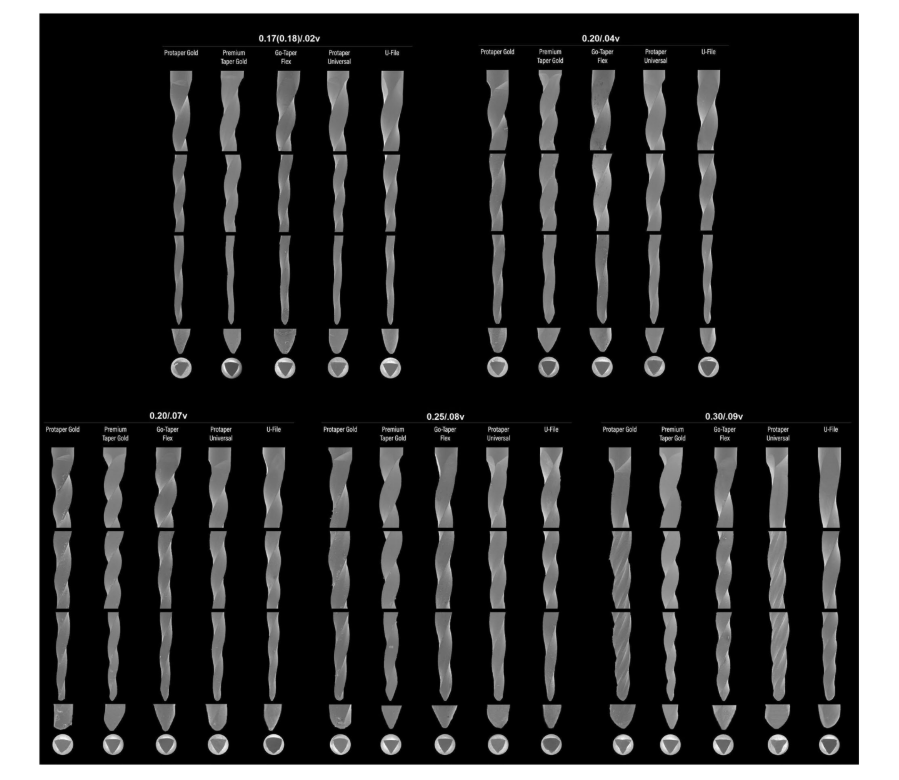

SEM analysis revealed that all sets of instruments had symmetrical spirals without radial lands, but with completely different tip geometry. All instruments of all systems had a convex cross-sectional triangular shape, except for Premium Taper Gold that presented a triangular geometry in 0.20/0.07v, 0.25/0.08v, and 0.30/0.09v files. Additionally, while PTG and PTU 0.30/0.09v instruments had a concave triangular cross-section, the other instruments had a triangular design (Fig. 1). Visual and microscopic analysis of all instruments reveals no major deformations or defects. In contrast, SEM analysis of instruments’ surfaces reveals that PTG, PTU, and Go-Taper Flex instruments had horizontal parallel marks resulting from the manufacturing process, while less irregularities were observed on the surface of Premium Taper Gold and U-File instruments (Fig. 2).

Metallurgical characterization

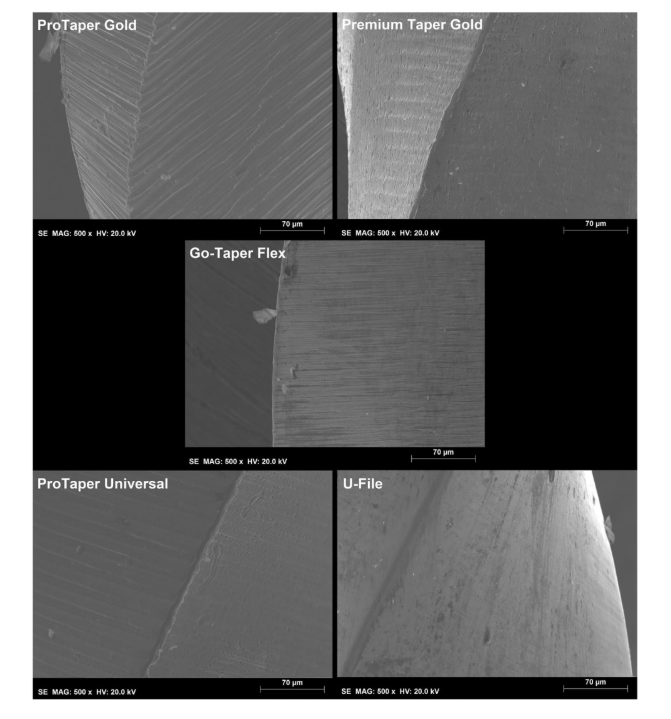

EDS/SEM analysis confirmed that all systems were made from NiTi alloy. In all instruments, nickel and titanium elements had an almost equiatomic proportion without any trace of other metallic component. At room temperature (20 °C), DSC test revealed martensitic characteristics for PTG (Rs ~ 49.0 °C; Rf ~ 31.1 °C) and Go-Taper Flex (Rs ~ 43.4 °C; Rf ~ 24.9 °C), and mixed austenite plus R-phase for the Premium Taper Gold (Rs ~ 26.8 °C; Rf ~ 16.1 °C), while PTU and U-Files had full austenitic characteristics (Rs temperatures lower than 20 °C) (Fig. 3).

Mechanical tests

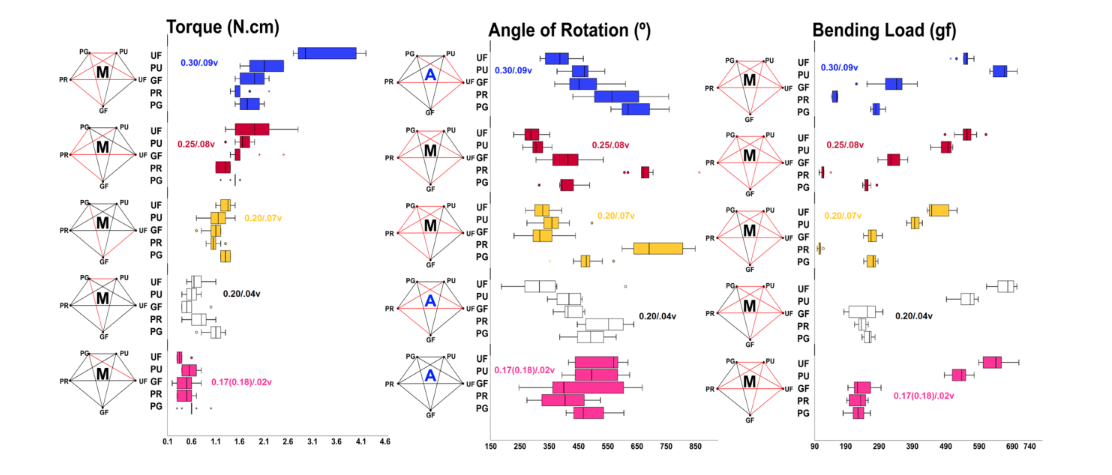

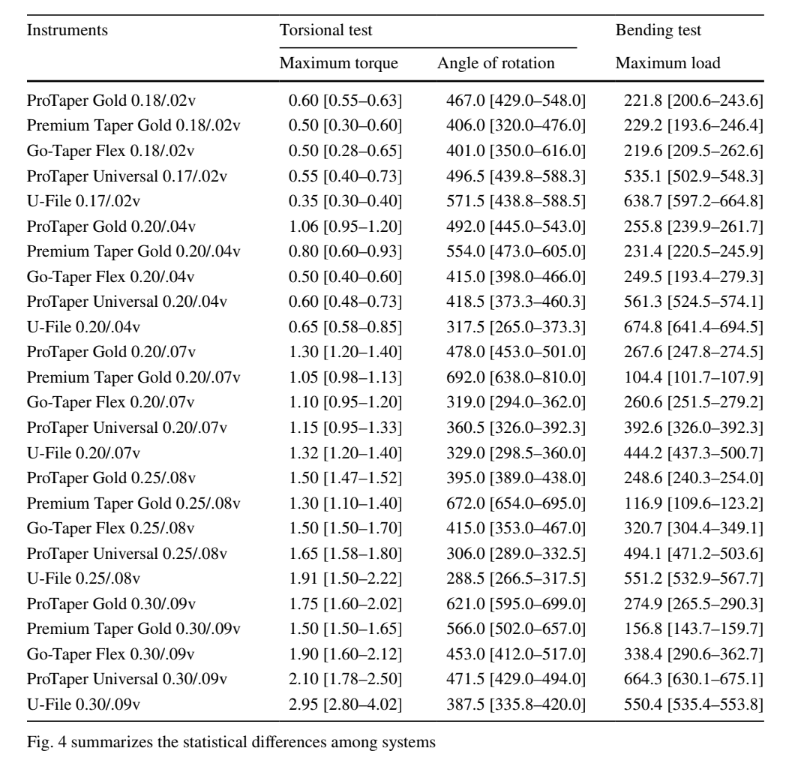

Overall, torque resistance and bending load results of 0.20/0.07v, 0.25/0.08v, and 0.30/0.09v instruments were higher than 0.17[0.18]/0.02v and 0.20/0.04v files, while a lack of consistency and mixed values were observed in the angle of rotation. Although some inconsistent results could be also observed in the other mechanical tests, 0.25/0.08v and 0.30/0.09v instruments of the PTU and U-File systems presented the highest maximum torques and bending loads (less flexibility), as well as the lowest angles of rotation (P < 0.05), when compared to the other 3 systems. A general overview according to the instruments’ sizes shows that the highest median torque values were found in the smaller sized PTG (0.18/0.02v with 0.60 N.cm; 0.20/0.04v with 1.06 N.cm) and larger U-File (0.20/0.07v with 1.32 N.cm; 0.25/0.08v with 1.91 N.cm; 0.30/0.09v with 2.95 N.cm) files, while the Premium Taper Gold system larger instruments had the lowest torque (P < 0.05). Premium Taper Gold also showed the lowest bending load (more flexibility) in 4 out of 5 instruments, and highest angle of rotation in 3 of them (Fig. 4; Table 2).

Root canal preparation

No statistical difference was observed among the rotary systems regarding the 3D morphometric parameters measured before or after shaping procedures (P > 0.05), and in the percentage of unprepared canal surface area (P > 0.05) (Table 3). No system was able to prepare the entire surface of the mesial and distal root canals of mandibular molars (Fig. 5).

Discussion

The multimethod research concept is described as a mixed method approach that simultaneously uses multiple qualitative and quantitative methodologies in the study design. The main advantage of the multimethod mixed research is the ability to offset the weaknesses of the tests included in the analyses. For instance, although differences among groups can be identified using quantitative methodologies, those differences might be difficult to justify or explain if they are not contextualized and integrated with non-quantifiable information. Therefore, a mixed multimethod approach provides more information, better understanding, and superior internal and external validation than a single or double method assessment. In the present study, results obtained in quantitative tests (maximum torque, angle of rotation, maximum bending load, unprepared surface canal area) of the basic full set of instruments (5 different sizes) from 5 rotary systems available in the market were explained based on their qualitative evaluation (overall design, surface finishing, and metal alloy crystallographic arrangement), and performed according to international guidelines or well-established and validated methodologies. Overall, results revealed differences in the mechanical properties of the systems and the first null hypothesis was rejected. On the other hand, the percentages of unprepared canal surfaces were similar among systems, leading to the acceptance of the second null hypothesis. In relation to the multimethod approach used in this study, it is important to point out that cyclic fatigue test was not included as a quantitative method of analysis considering the lack of standardized guidelines to test NiTi instruments and several methodological drawbacks recently reported in the literature.

It has been widely accepted that the design and metallurgical properties of rotary NiTi instruments have a significant impact on their mechanical performance. Overall, considering their large dimensions at D3 (position in which the instrument is locked during torsional test), the large-sized and tapered 0.20/0.07v, 0.25/0.08v, and 0.30/0.09v instruments showed higher torque resistance values than the smaller instruments. The mechanical parameter with more mixed results was the angle of rotation. It is hard to differentiate a typical behavior in the smaller 0.17[0.18]/0.02v instruments; however, lower angles of rotation were observed in the Go-Taper Flex, ProTaper Universal, and U-Files systems, which is somehow consistent with the high values observed in their maximum torque, an indicator of higher stiffness.

It may be assumed that alloy composition had no impact on the mechanical performance of the instruments, considering that all systems were made by similar amounts of nickel and titanium elements, without traces of other metals. On the other hand, the combination of the overall geometry, evaluated by stereomicroscopy and SEM, and the alloy crystallographic arrangement, determined by the DSC phase transformation temperature analysis, can partially explain almost all mechanical findings. For instance, the high number of spirals in the Premium Taper Gold system together with the small core volume of its instruments (triangular cross-section) (Fig. 1) are geometric characteristics that enhance flexibility. The association of these features with its better surface finishing (Fig. 2) and mixed austenite plus R-phase alloy (Fig. 3), characteristics that improve both flexibility and fracture resistance properties, helps to explain the overall lower maximum torque, higher angle of rotation, and lower bending load values of the Premium Taper Gold instruments compared to the other systems (Table 2; Fig. 4). In contrast, the full austenitic arrangement of the PTU (Rs ⁓10.6 °C) and U-File (Rs ⁓18.1 °C) (Fig. 3) explains their lower angle of rotation and higher bending load (less flexibility) compared to the other 3 martensitic systems (PTG, Premium Taper Gold, and Go-Taper Flex) (Fig. 4). Specific differences observed when comparing some PTU and U-File instruments, and also the martensitic systems (PTG and Go-Taper Flex) (Fig. 4), might be explained by the quality on their surface finishing (Fig. 2) and other characteristics not screened in the present investigation, such as the real dimensions of the instruments, considering that most of them were similar in terms of the other tested parameters.

Although many studies rely on mechanical parameters to assess the performance of rotary NiTi systems, a more comprehensive understanding should also include the assessment of their effectiveness in preparing the root canal system. It is well known that certain microorganisms can invade dentinal tubules at different depths and organized themselves into biofilms, which ultimately may lead to apical periodontitis. Taking this into consideration, the ability of a given mechanical instrument to scrape the dentinal walls gains special interest due to its potential capacity to remove infected dentine and/or disrupt bacterial biofilms. Therefore, the present multi-method research used a highly accurate, non-destructive, and well-established imaging methodology to assess the shaping ability of the tested systems regarding the percentage of dentinal walls touched by the instruments following the mechanical preparation protocol recommended by the manufacturers. While the metallurgical dissimilarities of tested instruments were clearly reflected in the results obtained in the mechanical testing, micro-CT evaluation of the percentage of unprepared areas of mesial root canals of mandibular molars revealed no difference among the systems (Table 3; Fig. 5). As previously reported, this parameter is not affected when comparing similar preparation protocols with similar instruments when proper care is taken to balance groups regarding morphometric parameters such as canal configuration, length, volume, surface area, and 3D geometry. In fact, this result corroborates a previous publication in which the original geometry of the root canal had a higher influence on the outcome of shaping procedures than preparation protocols. Notwithstanding punctual differences in specific instruments were not able to promote significant differences in root canal shaping. It is important to note that severe plastic deformations occurred in two 0.25/0.08v instruments and there was a fracture of one 0.18/0.02v instrument of the Premium Taper Gold system, possibly related to its design and metallurgical features, as previously commented.

For the micro-CT analysis, no pilot study was conducted considering that micro-CT technology was already validated for the evaluation of unprepared surface areas of root canal space after instrumentation. Thus, sample size estimation was initially conducted on a minor scale in order to evaluate feasibility, duration, cost, and adverse events, and to improve upon the study design prior to conducting a full-scale research project. Calculations were based on the results of the highest differences between 2 systems (Premium Taper Gold and Go-Taper Flex) in reference to the unprepared areas measured after shaping procedures of the first 3 paired canals, considering an effect size of 1.14, a standard deviation of 5.60, an 80% power, and an alpha-type error of 0.05. In these conditions, a total of 378 paired root canals per group are required to make statistical inference (i.e., the minimal sample size that would allow to observe difference among groups). In this study, however, instruments with similar dimensions were used to prepare strictly selected and matched canal anatomies. Besides, each tooth served as its own control since a non-destructive analytical tool was used to analyze the same specimen before and after the experimental protocols. This means that a similar outcome would be expected, as it was, confirming similar findings reported in previous publications. On the other hand, a different result would indicate a possible bias in sample selection and distribution, which is not the case of the present study. In summary, if someone expects to observe differences in such standardized conditions, a huge, unfeasible, and unrealistic sample size would be required, since the effect size is considerably small. Therefore, based on these arguments and considering the low clinical impact that this finding could have on such a large sample size (378 paired canals per group), a total of 11 canals were defined per group, following previous publications.

Overall, results obtained by testing PTU and PTG instruments corroborate previous reports in terms of nickel and titanium proportions, phase transformation temperatures, torsional and bending resistance tests, and unprepared canal surface area. Unfortunately, results from Premium Taper Gold, Go-Taper Flex, and U-File instruments were not possible to be compared with previous studies due to the lack of available information. The main strength of the present study was the use of a multimethod research protocol following international guidelines and well-established and previously validated methodologies. One of the main concerns regarding the evaluation of unprepared canal surface area is the anatomical bias that may work as a confounding factor. In order to ensure comparability, an initial effort was made to identify, select, and match the canals according to several morphometric parameters. Considering the ex vivo nature of this micro-CT evaluation, the external validity of the results tends to be higher than a pure laboratorial mechanical assessment of the rotary systems, which can be also considered another strength of this study. As limitations, the real dimensions of the instruments were not assessed, an information that could have added proper justification for some results, and that other tests, such as microhardness and cutting efficiency, could have been also used in this multimethod protocol. These limitations might be options for further studies.

Conclusions

The present multimethod research allowed to obtain important information of the main set instruments of 5 rotary systems through different perspectives, in order to evaluate their mechanical performance and shaping efficiency in terms of prepared canal surface areas. It was observed that instruments’ geometry and phase transformation temperatures influenced the results of the mechanical tests, but not the shaping procedure. PTU and U-File systems were full austenitic at testing temperature, while the others revealed martensitic characteristics. Overall, Premium Taper Gold instruments showed high angles of rotation and flexibility, while PTU and U-File instruments had low angles of rotation and high bending load resistance. Although no difference was observed in the percentage of unprepared canal surfaces among systems, Premium Taper Gold suffered permanent deformations in some instruments during canal preparation.

Authors: Jorge N. R. Martins, Emmanuel João Nogueira Leal Silva, Duarte Marques, Felipe Gonçalves Belladonna, Marco Simões‐Carvalho, Rui Pereira da Costa, António Ginjeira, Francisco Manuel Braz Fernandes, Marco Aurélio Versiani

References:

- Kuhn WG, Carnes DL Jr, Clement DJ, Walker WA (1997) Effect of tip design of nickel-titanium and stainless steel files on root canal preparation. J Endod 23:735–738

- Thompson SA (2000) An overview of nickel-titanium alloys used in dentistry. Int Endod J 33:297–310

- Sattapan B, Nervo GJ, Palamara JE, Messer HH (2000) Defects in rotary nickel-titanium files after clinical use. J Endod 26:161–165

- Silva E, Vieira VTL, Hecksher F, Dos Santos Oliveira MRS, Dos Santos AH, Moreira EJL (2018) Cyclic fatigue using severely curved canals and torsional resistance of thermally treated reciprocating instruments. Clin Oral Investig 22:2633–2638

- Blum JY, Cohen A, Machtou P, Micallef JP (1999) Analysis of forces developed during mechanical preparation of extracted teeth using Profile NiTi rotary instruments. Int Endod J 32:24–31

- Wei X, Ling J, Jiang J, Huang X, Liu L (2007) Modes of failure of ProTaper nickel-titanium rotary instruments after clinical use. J Endod 33:276–279

- McSpadden JT (2007) Mastering endodontic instrumentation. 1st edi. Cloudland Institute, Chattanooga

- Condorelli GG, Bonaccorso A, Smecca E, Schafer E, Cantatore G, Tripi TR (2010) Improvement of the fatigue resistance of NiTi endodontic files by surface and bulk modifications. Int Endod J 43:866–873

- Zhou H, Peng B, Zheng Y (2013) An overview of the mechanical properties of nickel–titanium endodontic instruments. Endod Top 29:42–54

- Elnaghy AM, Elsaka SE (2016) Mechanical properties of Pro-Taper Gold nickel-titanium rotary instruments. Int Endod J 49:1073–1078

- Martins JNR, Nogueira Leal Silva EJ, Marques D, Ginjeira A, Braz Fernandes FM, Deus G, Versiani MA (2020) Influence of kinematics on the cyclic fatigue resistance of replica-like and original brand rotary instruments. J Endod 46:1136–1143

- Alcalde M, Duarte MAH, Amoroso Silva PA, Souza Calefi PH, Silva E, Duque J, Vivan R (2020) Mechanical properties of Pro-Taper Gold, EdgeTaper Platinum, Flex Gold and Pro-T rotary systems. Eur Endod J 5:205–211

- Martins JNR, Silva E, Marques D, Belladonna F, Simoes-Carvalho M, Camacho E, Braz Fernandes FM, Versiani MA (2021) Comparison of design, metallurgy, mechanical performance and shaping ability of replica-like and counterfeit instruments of the ProTaper Next system. Int Endod J 54:780–792

- Love RM (2004) Invasion of dentinal tubules by root canal bacteria. Endod Top 9:52–65

- 15. Arnold M, Ricucci D, Siqueira JF Jr (2013) Infection in a complex network of apical ramifications as the cause of persistent apical periodontitis: a case report. J Endod 39:1179–1184

- Ricucci D, Candeiro GTM, Bugea C, Siqueira JF Jr (2016) Complex apical intraradicular infection and extraradicular mineralized biofilms as the cause of wet canals and treatment failure: report of 2 cases. J Endod 42:509–512

- Hunter A, Brewer JD (2015) Designing multimethod research. In: Hesse-Biber S, Johnson RB (eds) The Oxford handbook of multimethod and mixed methods research inquiry. Oxford University Press, Oxford

- ASTM International (2004) ASTM F2004 − 17: Standard test method for transformation temperature of nickel-titanium alloys by thermal analysis. 1–5

- ANSI/ADA Specification Nº28–2002. Root canal files and reamers, type K for hand use

- ISO3630–3631:2008. Dentistry – root canal instruments – Part 1: General requirements and test methods

- Martins JNR, Silva EJNL, Marques D, Belladonna F, Simões-Carvalho M, Vieira VTL, Antunes HS, Braz Fernandes FM, Versiani MA (2021) Design, metallurgical features, mechanical performance and canal preparation of six reciprocating instruments. Int Endod J 54:1623–1637

- Creswell JW (2014) Research design: qualitative, quantitative and mixed methods approaches, 4th edn. Sage Publications, Thousand Oaks

- Peters OA, Laib A, Ruegsegger P, Barbakow F (2000) Three-dimensional analysis of root canal geometry by high-resolution computed tomography. J Dent Res 79:1405–1409

- Hulsmann M (2019) Research that matters: studies on fatigue of rotary and reciprocating NiTi root canal instruments. Int Endod J 52:1401–1402

- Zupanc J, Vahdat-Pajouh N, Schafer E (2018) New thermomechanically treated NiTi alloys - a review. Int Endod J 51:1088–1103

- Kramkowski TR, Bahcall J (2009) An in vitro comparison of torsional stress and cyclic fatigue resistance of ProFile GT and Pro- File GT Series X rotary nickel-titanium files. J Endod 35:404–407

- Vieira AR, Siqueira JF Jr, Ricucci D, Lopes WSP (2012) Dentinal tubule infection as the cause of recurrent disease and late endodontic treatment failure: a case report. J Endod 38:250–254

- Peters OA, Schonenberger K, Laib A (2001) Effect of four Ni-Ti preparation techniques on root canal geometry assessed by micro computed tomography. Int Endod J 34:221–230

- Peters OA, Peters CI, Schonenberger K, Barbakov F (2003) Pro-Taper rotary root canal preparation: effects of canal anatomy on final shape analysed by micro CT. Int Endod J 36:86–92

- Zuolo ML, Zaia AA, Belladonna FG, Silva EJNL, Souza EM, Versiani MA, Lopes RT, De-Deus G (2018) Micro-CT assessment of the shaping ability of four root canal instrumentation systems in oval-shaped canals. Int Endod J 51:564–571

- Stringheta CP, Bueno CES, Kato AS, Freire LG, Iglecias EF, Santos M, Pelegrine RA (2019) Micro-computed tomographic evaluation of the shaping ability of four instrumentation systems in curved root canals. Int Endod J 52:908–916

- Silva E, Martins JNR, Lima CO, Vieira VTL, Fernandes FMB, De-Deus G, Versiani MA (2020) Mechanical tests, metallurgical characterization and shaping ability of NiTi rotary instruments: a multimethod research. J Endod 46:1485–1494

- Weyh DJ, Ray JJ (2020) Cyclic fatigue resistance and metallurgic comparison of rotary endodontic file systems. Gen Dent 68:36–39

- Hieawy A, Haapasalo M, Zhou H, Wang ZJ, Shen Y (2015) Phase Transformation behavior and resistance to bending and cyclic fatigue of ProTaper Gold and ProTaper Universal instruments. J Endod 41:1134–1138

- Versiani MA, Leoni GB, Steier L, De-Deus G, Tassani S, Pecora JD, de Sousa-Neto MD (2013) Micro-computed tomography study of oval-shaped canals prepared with the self-adjusting file, Reciproc, WaveOne, and ProTaper Universal systems. J Endod 39:1060–1066