Diamondlike Carbon Surface Treatment Improves the Fatigue Resistance of Ultrasonic Tips

Abstract

Introduction: The aim of this study was to compare E1-Irrisonic (Helse Ultrasonics, Ocoee, FL) and Irri Black (Helse Ultrasonics), a novel ultrasonic tip with diamondlike carbon treatment, regarding their design, metallurgy, microhardness, bending resistance, and time to fracture under the oscillatory fatigue test.

Methods: A total of 17 E1-Irrisonic and 17 Irri Black new ultrasonic tips were selected. The tip geometry and surface finishing were assessed using scanning electron microscopy. The elemental composition was defined by energy-dispersive X-ray spectroscopy. Hardness Knoop was calculated using a microhardness tester. The maximum load required to displace the instrument in 45° was recorded in gram/force, oscillatory fatigue was measured in seconds at the moment of instrument fracture, and the size of the separate fragments was determined in millimeters. The Student t test was used for statistical comparison (a = 5%).

Results: Scanning electron microscopic analyses revealed that E1-Irrisonic had a flat end tip, whereas a noncutting rounded tip was observed in Irri Black. The surface of E1-Irrisonic was smoother than Irri Black, which was irregular. Energy-dispersive X-ray spectroscopic analyses showed that the elemental compositions of the E1-Irrisonic and Irri Black tips were consistent with stainless steel and titanium-aluminum alloys, respectively. Irri Black showed significantly higher bending load resistance, time to fracture under oscillatory motion, and hardness Knoop than the E1-Irrisonic tip (P ˂ .05), whereas the length of fragments was similar (P ˃ .05).

Conclusion: Diamondlike carbon treatment improved hardness Knoop and reduced the flexibility of the Irri Black ultrasonic tip, improving its time to fracture under oscillatory motion compared with the nontreated E1-Irrisonic tip. (J Endod 2023;49:301–306.)

Irrigation is an essential step to optimize root canal cleaning and disinfection by reaching areas untouched by endodontic instruments. In necrotic cases, dentin debris and the smear layer produced during mechanical preparation may be infected and can inactivate root canal medicaments and irrigants and/or block their access to the biofilm. In addition, because of the complexity of the root canal system, research has continuously shown that conventional irrigation with a syringe and needles fails to clean lateral canals, oval extensions, isthmuses, and irregularities on the root canal walls. Therefore, in order to improve disinfection, irrigation must provide not only an adequate flow of the irrigant to the full extent of the root canal system during chemomechanical preparation but also an enhancement in its streaming by an energy source.

Richman is credited for being the first author to report the application of ultrasound in endodontics in 1957, but it was only in 1976 that Martin suggested the activation of endodontic instruments as a primary method of canal preparation and debridement in root canal therapy. Nowadays, there are several concepts, systems, and mechanisms available to activate the irrigant solution, but 1 of the most used techniques is the ultrasonic activated irrigation (UAI), which was previously known as passive ultrasonic irrigation. UAI is based on the transmission of an acoustic mechanical energy through the irrigation solution by the action of an energy source coupled to an insert or a file. The ultrasonic oscillation of this instrument induces streaming of the fluid around it, leading to alternating pressures and shear stresses on the root canal walls, optimizing the quality of cleaning and disinfection compared with conventional techniques. On the other hand, the oscillatory nature of the pressure and the shear stress may induce fatigue to the material, increasing the risk of breakage. The effectiveness of UAI in a clinical setup can be improved by inserting the ultrasonic tip within 2–3 mm from the working length in a root canal previously enlarged to a minimal apical size 30 or 35.

E1-Irrisonic (size 20, 0.01 taper; Helse Ultrasonics, Ocoee, FL) is a stainless steel ultrasonic tip recommended for the UAI technique. Previous studies demonstrated its ability to improve canal disinfection and remove hard tissue debris or filling remnants. Recently, a new generation of this tip, the Irri Black (size 20, 0.01 taper; Helse Ultrasonic), was launched onto the market. According to the manufacturer, this instrument has the same design of its predecessor but undergoes a diamondlike carbon (DLC) coating treatment with layer doping with titanium, zirconium, niobium, and other elements that adds a black layer on its surface, which improves hardness, chemical resistance, resistance to fracture, and the tribological properties of the ultrasonic tip.

In the literature, most of the studies have tested ultrasound as a primary method of canal preparation or as an adjunct for cleaning and disinfection, whereas only a few publications explored the mechanical properties of ultrasonic tips, such as cutting efficiency and breakage resistance. Until now, no study has evaluated ultrasonic tips developed for the UAI technique regarding its metallurgical characteristics and mechanical properties. Therefore, the aim of this study was to compare the E1-Irrisonic and Irri Black instruments regarding their design, metallurgical characteristics, hardness Knoop, bending resistance, and time to fracture under an innovative oscillatory fatigue test (OFT). The null hypothesis tested was that E1-Irrisonic and Irri Black had no significant differences in the tested parameters.

Materials and methods

Thirty-four new E1-Irrisonic (n = 17) and Irri Black (n = 17) ultrasonic tips were randomly selected and tested regarding design, surface finishing, metallurgy, microhardness, bending resistance, and oscillatory fatigue.

Design and Surface Finishing

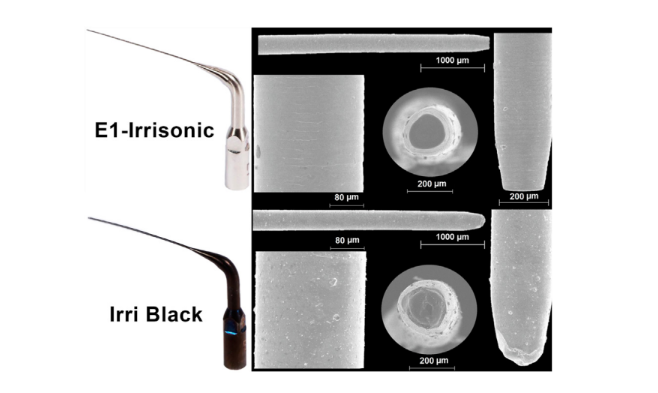

At first, all instruments were visually inspected for major defects, and no instrument was discarded. The design and surface finishing of the E1-Irrisonic (n = 3) and Irri Black (n = 3) ultrasonic tips were assessed under scanning electron microscopy (S-2400; Hitachi, Tokyo, Japan) at X30, X150, and X400 magnifications.

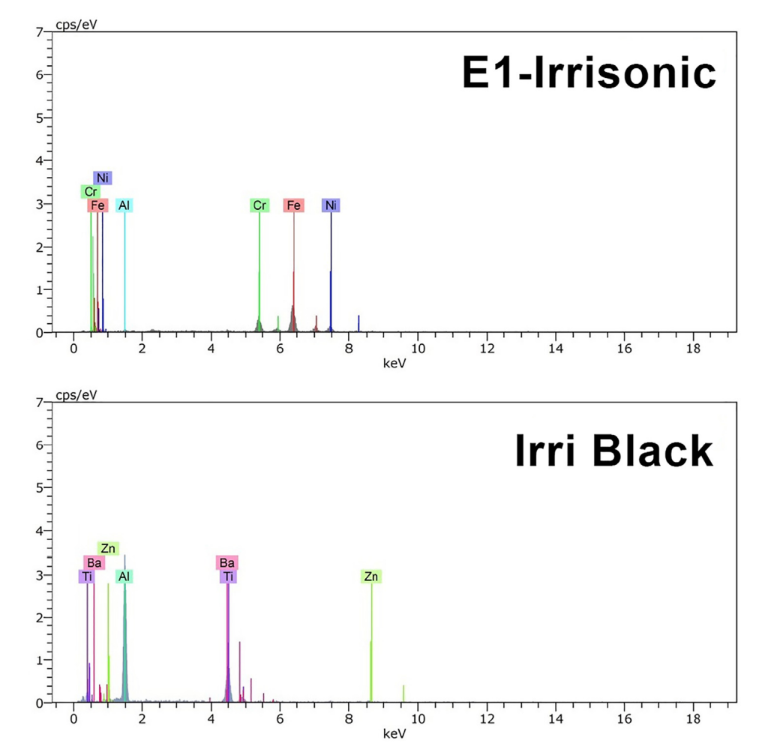

Metallurgy

The E1-Irrisonic and Irri Black tips were cleaned by immersion in an acetone bath for 2 minutes. Each instrument was then mounted on a sample holder, placed into the chamber of a scanning electron microscopic device (S-2400) set at 20 kW and 3.1 A, and positioned at a working distance of 25 mm of an energy-dispersive X-ray spectroscopic detector (Bruker Quantax; Bruker Corporation, Billerica, MA). A vacuum was created for ~10 minutes, and acquisitions (conducted on an area of 400 μm X 400 μm) were made with a 60-second lifetime for optimized image conditions with ~30% death time. The elemental analysis was semiquantitative using the ZAF correction, and the results were evaluated on dedicated software (Systat Software Inc, San Jose, CA). Two tips of each type were tested to confirm the results, and each instrument was evaluated in triplicate.

Microhardness Test

The sample size for this test was calculated based on the difference obtained after 3 initial measurements performed on the selected tips with 80% power and an alpha-type error of 0.05. Considering the effect size of 14.5, a total of 6 indentations were established per group. Thus, 2 E1-Irrisonic and 2 Irri Black tips were selected, and 3 indentations were performed in each instrument for a total of 6 indentations per group. The ultrasonic tip was stabilized in an acrylic support, and the diamond penetrator of a HV-1000 Vickers microhardness tester (Sinowon, DongGuan, China) was positioned on its surface and set to perform a 100 g/force press load for 15 seconds. The evaluation of indentations was performed at X40, and the values of microhardness are expressed as hardness Knoop.

Bending Resistance and OFT

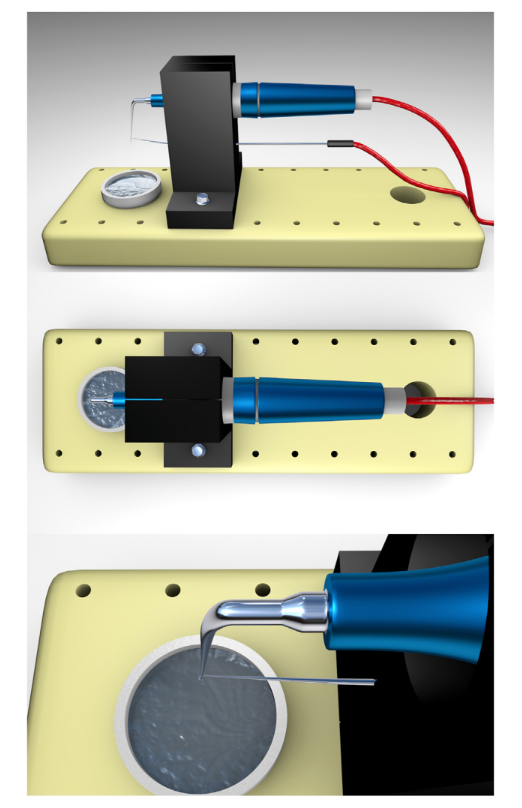

The sample size was estimated for each test by taking the difference obtained after 3 initial measurements using a power level of 80% and an alpha-type error of 0.05. A total of 4 and 2 instruments were determined for the bending resistance test (effect size = 2.44) and the OFT (effect size = 13.5), respectively, and the final sample size was established as 5 instruments per group for each test. In the bending test, each ultrasonic tip was positioned 45° in relation to the floor, whereas its apical 3 mm was attached to a wire connected to a universal testing machine (Instron, Norwood, MA). The maximum load required to displace the instrument in 45° using a load of 20 N and 15 mm/min constant speed was recorded in gram/force. The OFT was performed in a device that consists in a piezoelectric ultrasonic unit (Newtron Booster; Satelec Acteon, Me’rignac, France) driven at frequencies of 28–36 kHz and automatically operated with maximum power settings (20/20). The ultrasonic tip was mounted in light contact with a piece of wire connected to an electronic stopwatch and activated freely in the air under water cooling of the piezoelectric unit for 60-second cycles, with 2 seconds between each cycle (Fig. 1). This process was repeated until breakage was observed. At this moment, the electric circuit was interrupted, the ultrasonic unit stopped automatically, and the time to fracture was recorded in seconds. Then, the length of the fractured fragment was measured using a digital caliper (Mitutoyo, Aurora, IL).

Results

Scanning electron microscopic analyses revealed that E1-Irrisonic had a flat end tip, whereas a noncutting rounded tip was observed in the Irri Black. The surface of E1-Irrisonic was smoother than the Irri Black, which was irregular. There were no pits, defects, or potential fracture points on the surface of both tips (Fig. 2).

rounded tip was observed in Irri Black. The surface of E1-Irrisonic was smoother than Irri Black, which showed marks

compatible with a coating surface.

Energy-dispersive X-ray spectroscopic analyses showed that the elemental compositions of the E1-Irrisonic and Irri Black tips were consistent with stainless steel (Fe ⁓64.4%, Cr ⁓19.3%, and Ni ~13.5%) and titanium-aluminum (Ti ⁓35.8% and Al ⁓54.5%) alloys, respectively (Fig. 3).

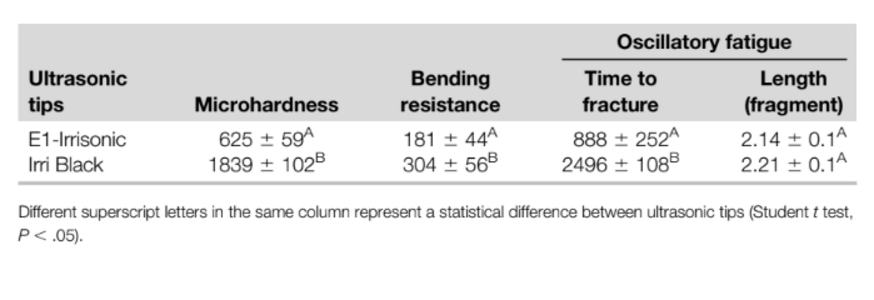

Irri Black showed significantly higher bending load resistance, time to fracture under oscillatory motion, and hardness Knoop than the E1-Irrisonic tip (P ˂ .05) (Table 1). No difference was observed in the length of fragments measured after the OFT (P ˃ .05) (Table 1).

Discussion

Instrument fracture has been a frequent finding in clinical practice that could jeopardize the success rate of endodontic treatment. In the past, there were some reports on the breakage of ultrasonic files during canal instrumentation and ultrasonic tips in root end preparation. These mishaps were attributed to clinical mishandling or manufacturing flaws and reduced strength due to instrument design. Such fractures occurred primarily at the nodes of the vibrating tip, which is a point of maximum strain. The pattern of nodes and antinodes along an ultrasonically driven instrument is what determines the flow in the axial, whereas their multitude leads to a more complex pattern of microstreaming along the instrument. Thus, the evaluation of the main characteristics of instruments used for root canal treatment is necessary to provide proper understanding of their mechanical performances. This study presents original and innovative results because this is the first investigation that assessed the design and compared the metallurgical and mechanical properties of 2 ultrasonic tips (E1-Irrisonic and Irri Black) developed to be used as an adjunctive step to improve root canal cleaning and disinfection. The analyses of the results rejected the null hypothesis because statistically significant differences were observed in the tested parameters.

The analyses of the E1-Irrisonic and Irri Black instruments using scanning electron microscopy demonstrated differences in the geometry of their tips as well as in their surface finishing (Fig. 2). Although E1-Irrisonic showed a flat end tip, a noncutting rounded tip was observed in Irri Black. According to the manufacturer, the design of E1-Irrisonic and Irri Black (including their tips) is the same, and they only differ in terms of DLC treatment. Thus, it may be inferred that the noncutting rounded tip of Irri Black is a result of the DLC surface treatment. Although these instruments were designed to be used in already enlarged root canals, the presence of a sharp edge at the tip of E1-Irrisonic may be a risk for damage to the dentin, especially in curved canals. It is unlikely that this instrument would be able to cause a ledge in the canal walls, but depending on the irregularities created at the apical third, it may compromise the sealing quality of filling materials at this area; this is an issue to be explored in future studies. On the other hand, the rounded tip associated with a round cross section of the Irri Black instrument would help to prevent these mishaps. Another difference observed in these instruments was related to their surfaces. Irri Black showed several irregularities on its surface compared with E1- Irrisonic. This surface characteristic can also be found in other instruments submitted to the DLC coating treatment as reported in the literature. It has been suggested that these irregularities are associated with a kind of coating delamination, a process related to the loss of coating adhesion to a surface or between coating layers.

Energy-dispersive X-ray spectroscopic analysis revealed that the elemental compositions of E1-Irrisonic and Irri Black tips were consistent with stainless steel and titanium-aluminum alloys, respectively. Ozkomur et al investigated the effect of DLC coating over titanium on galvanic corrosion behavior between titanium and the Ni-Cr alloy and concluded that DLC coating may serve as an insulating film layer over the surface preventing galvanic coupling. In other studies, it was demonstrated that the DLC coating process also reduced the frictional force of orthodontic wires and brackets. Taken together, these results suggest that instruments coated with a DLC layer are subjected to less static and kinetic frictional forces than stainless steel while serving as a galvanic corrosion barrier, which may result in long-term strength.

There are only a few publications using different methods to evaluate the fracture resistance of ultrasonic tips. Walmsley et al used a double-pan balance and reported that breakage was more likely to occur in tips with excessive angulation and bending. Lin et al evaluated the cutting efficiency of the 3 different ultrasonic tips (stainless steel, zirconium nitride coated, and diamond coated) used for orthograde endodontic treatment and reported that only diamond-coated tips broke. Wan et al compared the breakage of 3 endodontic ultrasonic tips when removing dentin from extracted molars, and the results were consistent with those observed by Lin et al. One of the main strengths of this study was to present a new proposal to determine the time to fracture of ultrasonic tips under activation, which is the most common mishap observed in clinical practice. In this study, the OFT was performed in an automatic device that consists in an ultrasonic unit operating with cycles of 60 seconds with rest periods of 2 seconds at maximum power settings (20/20). This setup was chosen because in a pilot study the power setting recommended by the manufacturer (10% power level) was insufficient to fracture the instruments, even when operating for a long period of time. Using the manufacturer’s directions is an important aspect to be considered for the clinical use of the tested ultrasonic tips; however, from a methodological point of view, it does not allow the measurement of the time to fracture. Also, previous studies used maximum power settings when testing the fracture resistance of other types of ultrasonic tips. On the other hand, although one may argue that the lack of fracture of the tested tips operating under a low-power setting may confirm their efficacy, ultrasonic tips developed for UAI procedures also have a risk of fracture. It is of note that the OFT was conducted without curving the ultrasonic tips, which might have contributed to the lack of fracture under low-power settings. This was 1 of the limitations of this study that could be tested in future studies.

The hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of a material, aiming to determine its resistance to permanent deformation. In this study, the hardness values of the DLC-coated Irri Black were significantly higher than those of the stainless steel E1-Irrisonic instrument (Table 1). An increase in hardness is often the most noted improved property observed in DLC-coated instruments. Most DLC films are harder than most metallic materials, and DLC coating gives hardness values ranging from

6–20 GPa depending on the deposition conditions. In addition, the literature has demonstrated that DLC coating can prevent corrosion and improve wear resistance and hardness when applied to the surface of medical devices, which may explain the significantly higher time to fracture and bending load of Irri Black compared with the E1-Irrisonic tip (Table 1). The improved time to fracture of the DCL-coated ultrasonic instruments is beneficial in clinical practice because it may prevent unexpected breakage during the activation of irrigants inside the root canal system.

However, it is important to emphasize that the coating process also significantly reduced the flexibility of the Irri Black tip (Table 1), an aspect that should be evaluated in future studies in order to determine if this reduction could compromise its efficiency, mostly when used in curved canals.

Although this article reported original results using a novel method to evaluate the fracture resistance of ultrasonic tips, it also presented limitations. For instance, only 1 ultrasonic unit was used, and the time to fracture may differ depending on the device. Tips were also tested by activating them freely in the air under water cooling and not immersed into a liquid or within the root canal space to simulate its clinical use. Finally, tips were kept straight, and future studies might be conducted using the OFT under curved conditions. In fact, manufacturers should be aware of the main causes of fracture and use sound scientific principles and quality control to develop new ultrasonic tips. In this way, more studies on mechanical and metallurgical properties that affect the fracture resistance of ultrasonic tips are required so that clinicians might be better informed when selecting tips for a particular procedure. Under the limitations of this study, it may be concluded that DLC treatment improved hardness Knoop and reduced the flexibility of the Irri Black ultrasonic tip, improving its time to fracture under oscillatory motion compared with the nontreated E1-Irrisonic ultrasonic tip.

Authors: Emmanuel J. N. L. Silva, Bruno M. Crozeta, Jorge N. R. Martins, Thiago Moreira, Victor T. L. Vieira, Francisco Manuel Braz-Fernandes, and Marco A. Versiani

References

- Haapasalo M, Qian W, Portenier I, Waltimo T. Effects of dentin on the antimicrobial properties of endodontic medicaments. J Endod 2007;33:917–25.

- Linden D, Boone M, De Bruyne M, et al. Adjunctive steps for the removal of hard tissue debris from the anatomic complexities of the mesial root canal system of mandibular molars: a micro-computed tomographic study. J Endod 2020;46:1508–14.

- van der Sluis LW, Versluis M, Wu MK, Wesselink PR. Passive ultrasonic irrigation of the root canal: a review of the literature. Int Endod J 2007;40:415–26.

- Richman MJ. The use of ultrasonic in root canal therapy and root resection. J Dent Med 1957;12:8–12.

- Martin H. Ultrasonic disinfection of the root canal. Oral Surg Oral Med Oral Pathol 1976;42:92–9.

- Boutsioukis C, Verhaagen B, Walmsley AD, et al. Measurement and visualization of file-to-wall contact during ultrasonically activated irrigation in simulated canals. Int Endod J 2013;46:1046–55.

- Ahmad M, Pitt Ford TJ, Crum LA. Ultrasonic debridement of root canals: acoustic streaming and its possible role. J Endod 1987;13:490–9.

- van der Sluis L, Verhaagen B, Macedo RG, Versluis A. Disinfection of the root canal system by sonic, ultrasonic, and laser activated irrigation. In: Cohenca N, editor. Disinfection of Root Canal Systems: The Treatment of Apical Periodontitis. 1 ed. Oxford, UK: John Wiley & Sons, Inc; 2014. p. 217–38.

- Flemming H-C, Wingender J, Szewzyk U. Biofilm Highlights. Springer Series on Biofilms. 1 ed. Berlin, Germany: Springer; 2011.

- Capelli A, Duarte MAH, Vivan R, et al. New resources to mitigate failure in root canal treatment and retreatment. Endod Practice USA 2018;10:28–33.

- Nakamura VC, Pinheiro ET, Prado LC, et al. Effect of ultrasonic activation on the reduction of bacteria and endotoxins in root canals: a randomized clinical trial. Int Endod J 2018;51(Suppl 1):e12–22.

- Silva EJNL, Carvalho CR, Belladonna FG, et al. Micro-CT evaluation of different final irrigation protocols on the removal of hard-tissue debris from isthmus-containing mesial root of mandibular molars. Clin Oral Investig 2019;23:681–7.

- Crozeta BM, Lopes FC, Menezes Silva R, et al. Retreatability of BC Sealer and AH Plus root canal sealers using new supplementary instrumentation protocol during non-surgical endodontic retreatment. Clin Oral Investig 2021;25:891–9.

- Nalwa HS. Handbook of Thin Film Materials. 1 ed. San Diego: Academic Press; 2002.

- Plotino G, Pameijer C, Mariagrande N, Somma F. Ultrasonics in endodontics: a review of the literature. J Endod 2007;33:81–95.

- Paz E, Satovsky J, Moldauer I. Comparison of the cutting efficiency of two ultrasonic units utilizing two different tips at two different power settings. J Endod 2005;31:824–6.

- Lin YH, Mickel AK, Jones JJ, et al. Evaluation of cutting efficiency of ultrasonic tips used in orthograde endodontic treatment. J Endod 2006;32:359–61.

- Wan J, Deutsch AS, Musikant BL, Guzman J. Evaluation of the breakage of orthograde endodontic ultrasonic tips. J Endod 2014;40:2074–6.

- Walmsley AD, Lumley PJ, Johnson WT, Walton RE. Breakage of ultrasonic root-end preparation tips. J Endod 1996;22:287–9.

- Panitvisai P, Parunnit P, Sathorn C, Messer HH. Impact of a retained instrument on treatment outcome: a systematic review and meta-analysis. J Endod 2010;36:775–80.

- Spili P, Parashos P, Messer HH. The impact of instrument fracture on outcome of endodontic treatment. J Endod 2005;31:845–50.

- Scott GL, Walton RE. Ultrasonic endodontics: the wear of instruments with usage. J Endod 1986;12:279–83.

- Ahmad M. An analysis of breakage of ultrasonic files during root canal instrumentation. Endod Dent Traumatol 1989;5:78–82.

- Ahmad M, Roy RA. Some observations on the breakage of ultrasonic files driven piezoelectrically. Endod Dent Traumatol 1994;10:71–6.

- Martins JNR, Silva E, Marques D, et al. Evaluation of design, metallurgy, microhardness, and mechanical properties of glide path instruments: a multimethod approach. J Endod 2021;47:1917–23.

- Ozkomur A, Erbil M, Akova T. Diamondlike carbon coating as a galvanic corrosion barrier between dental implant abutments and nickel-chromium superstructures. Int J Oral Maxillofac Implants 2013;28:1037–47.

- Muguruma T, Iijima M, Brantley WA, Mizoguchi I. Effects of a diamond-like carbon coating on the frictional properties of orthodontic wires. Angle Orthod 2011;81:141–8.

- Muguruma T, Iijima M, Brantley WA, et al. Frictional and mechanical properties of diamond-like carbon-coated orthodontic brackets. Eur J Orthod 2013;35:216–22.

- Batista Mendes GC, Padovan LE, Ribeiro-Junior PD, et al. Influence of implant drill materials on wear, deformation, and roughness after repeated drilling and sterilization. Implant Dent 2014;23:188–94.

- Wuchenich G, Meadows D, M T. Comparison of retrograde cavities prepared by ultrasonic tips and burs. J Endod 1993;19:206.

- Cunha TC, Matos FS, Paranhos LR, Moura CCG. Treatment outcome of young molars obstructed by fractured endodontic instruments: two case reports. RSD 2020;9:e3149108537.

- Hauert R. A review of modified DLC coatings for biological applications. Diam Relat Mater 2003;12:583–9.

- Sridharan K, Anders S, Nastasi M, et al. Nonsemiconductor applications of PIII&D. In: Anders A, editor. Handbook of Plasma Immersion Ion Implantation and Deposition. New York: Wiley & Sons; 2000.

- Shirakura A, Nakaya M, Koga Y, et al. Diamond-like carbon films for PET bottles and medical applications. Thin Solid Films 2006;494:84–91.

- Donnet C, Fontaine J, Le Mogne T, et al. Diamond-like carbon-based functionally gradient coatings for space tribology. Surf Coat Technology 1999;120-121:548–54.