Laser Welding in Orthopedic Dentistry

Machine translation

Original article is written in RU language (link to read it) .

As of today, soldering is considered an outdated technology for manufacturing orthopedic structures, although it is a simple way to solve problems associated with metal frames.

About the technique of intraoral welding in the webinar Immediate load using intraoral welding. Conometric concept.

Disadvantages of soldering that are easily solved by welding

This technology has a number of disadvantages. The main one is the need to heat the soldering area of the frame to a sufficiently high temperature, which exceeds the melting temperature of the solder. The result is undesirable oxidation, burning out of organic components of the structure, and thinning of the frame sections, worsening the bond with the frame.

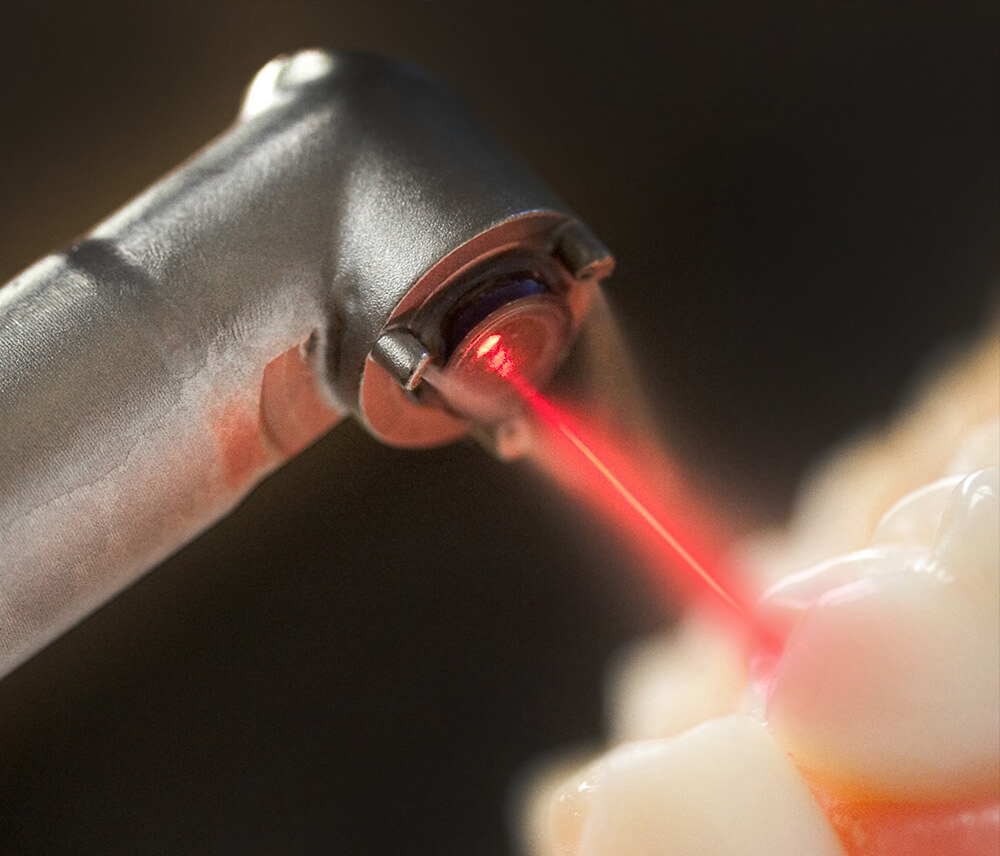

Figure 1. Laser welding in dentistry.

The next disadvantage is the thinning of the structure due to partial conversion to oxides, which are additionally polished, causing the prosthesis to lose resistance to loads, and in extreme cases, holes are formed.

The importance of laser welding cannot be overstated when, after fitting the framework, it becomes necessary to extend the edge of the crown. Without a welding device, the framework must be completely remade, recast, and the missing fragment soldered.

During the soldering process, the framework heats unevenly, causing internal expansion stresses, which provoke cracking and delamination of the brittle veneer coating.

The use of lasers also corrects other problems, such as if externally polished areas contain chips formed due to inclusions of slag, remnants of the casting crucible or molding compound, or depressions that were not noticed on the wax model or were acquired during casting. Defects of other origins are also identified, such as volumetric pores due to shrinkage, which are eliminated by smoothing the surface with a laser, where the beam is focused with a larger diameter, only slightly melting the area of the prosthesis to a minimal depth.

Figure 2. Cast prosthesis after repair by laser welding.

Another drawback is due to the fact that soldering uses solder whose melt absorbs carbon, the flame of the torch contains hydrocarbons, as a result, the solder is enriched with carbon, its composition changes and homogeneity is lost, which is the basis for adverse consequences (deformation and breakage of the entire structure).

The next drawback is the galvanic currents that develop in the patient's oral cavity due to prosthetics, even if all structures were made from the same alloy.

The fifth drawback is due to the use of soldering flux. Soldering sometimes helps to solve one problem, creating the conditions for another to arise. This occurs during the process of eliminating the consequences of incorrect installation of the gating system, causing the formation of narrow pores, microporosity, surface collapses, cracks, and fractures. During the sealing of these defects, the heated flux can be absorbed into the structure, and later, during the firing of ceramics, it comes out through the microvoids.

At this point, the list of soldering drawbacks can be concluded, mentioning also the significantly weaker strength of the soldered joint compared to solid metal, which is particularly important when using fragile veneers. The fragile solder transfers reversible load deformations with difficulty.

Figure 3. Spot welding machine.

To improve the quality of prosthetics, it is advisable to use solderless connection methods in the repair and manufacture of orthopedic structures, among which laser welding is included.

Advantages of Laser Welding

There are a number of undeniable advantages characteristic of laser welding of metal construction parts of orthodontic devices and orthopedic prostheses.

- Laser radiation has low divergence, which allows it to be precisely focused on a small area, resulting in a powerful beam of high density, capable of welding refractory materials that are difficult to weld.

- The non-contact nature of the operation and the ability to transmit radiation via a fiber optic cable allows welding in hard-to-reach areas.

- The welds obtained using lasers are characterized by a small zone of thermal impact on the surrounding material, which serves as a prevention of possible thermal deformations.

- There is no need for additional materials such as fluxes and solders.

- Limited locality of the radiation action helps to process a fragment of the structure close to thermosensitive areas.

- The short duration of laser welding prevents adverse structural changes.

- The speed of welding is quite high.

- The welding process is automated.

- The specialist can easily and quickly maneuver the shape, duration, and energy of the laser energy, which provides flexibility in controlling the technological welding process.

Currently, laser technologies have gained well-deserved popularity in modern dentistry. Against the background of increasing population allergies and the development of resistance to many drugs, laser therapy serves as an alternative to medicinal influence. The biocompatibility and non-traumatic nature of laser surgery have allowed the replacement of the scalpel with laser radiation in many surgical interventions, which helped minimize side effects, and some procedures were performed for the first time.

Figure 4. Use of laser in dentistry.

Laser Welding Mechanism

Let's take a closer look at the laser welding process. The power supply of the laser unit converts the alternating current from the network into powerful energy, which is transmitted to the electrodes of the pumping lamp. The laser radiation, coming out of the resonator, is focused on the welding surface in the form of a spot with a small diameter, no more than 1 mm. A smaller portion of the radiation hitting the prosthesis is reflected, most of it is absorbed, used to heat the material and melt it. If the radiation energy is too high per unit of surface area in the focus zone, evaporation of the material can occur, which is accompanied by its splashing.

The pulsed light flow created by the laser is focused on the joint of metallic surfaces in a spot 1 mm in diameter. In the area of the joint, the melted metal flows into the gap formed by the parts, and as it solidifies, it forms a welded spot connection due to fusion.

Details are moved at the beginning of the next laser pulse impact to allow partial overlap of the welding point with the previous one, thus forming a weld seam.

The energy of the laser radiation is determined by the charge voltage, another important indicator of laser welding is the size of the focus spot, as well as the degree of overlap of the welding points. By smoothly changing these characteristics, the specialist selects the most optimal welding mode for a specific part, taking into account the features of the part configuration and its chemical composition.

Figure 5. Laser scalpel in dentistry.

Laser radiation, when interacting with material, causes a chain of complex interconnected processes, which are more or less manifested on the treated surface:

- absorption of laser energy by the metal surface, heating of the material and heat distribution;

- thermal destruction and thermoelastic deformation of the material, melting of the metal and surface evaporation thereof;

- under the pressure, the melt moves, possible splashes, transfer to contact surfaces, convective mixing;

- heating of the material;

- plastic deformation of metal surfaces occurs;

- further propagation of laser radiation;

- cooling and solidification of the melt, which is accompanied by structural and chemical transformations.

The final result of laser welding is sensitive to the subtle characteristics of the radiation, the quality of the surface of the material being welded, and the composition of the original alloy. These internal interconnections of the mentioned processes contribute to the development of a number of instabilities and fluctuations, significantly affecting the final result.

During laboratory research, it was established that there is a need to develop and manufacture devices that would ensure the most accurate positioning and securing of parts being joined by laser welding of complex configurations, which include most of the composite components of orthopedic structures and orthodontic devices.

Electrical welding in the oral cavity: the principle of operation of the equipment in the webinar Immediate loading using intraoral electric welding in complete edentulism.